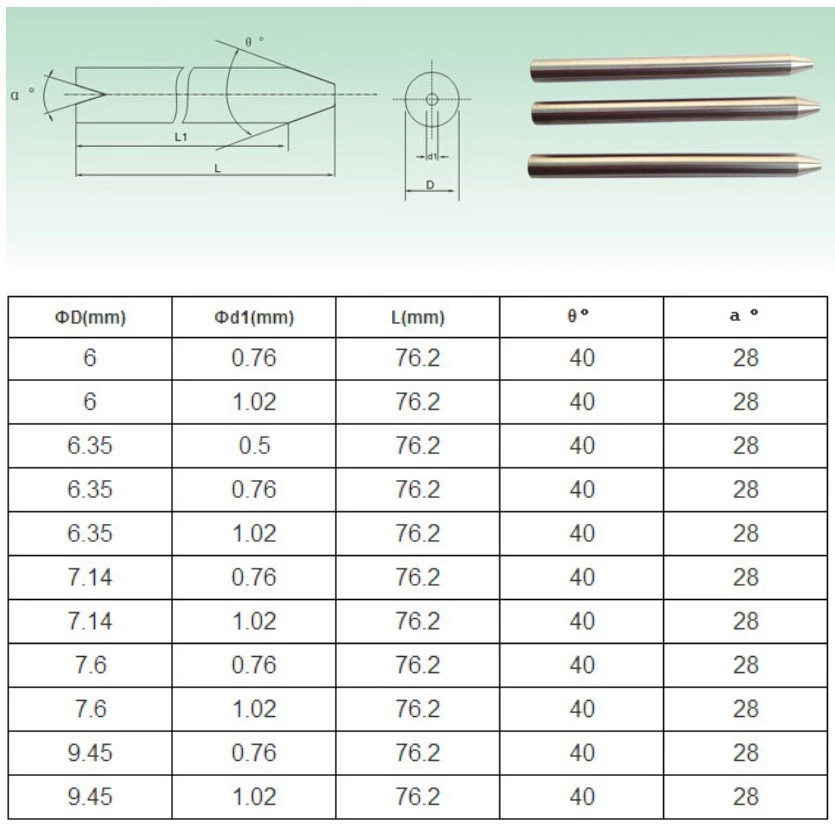

Tungsten Carbide Nozzle

High Hardness And Wear-resistance Tungsten Carbide Waterjet Nozzle

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: K10,K20,K30

- Price:Quote based on drawings

High Hardness And Wear-resistance Tungsten Carbide Waterjet Nozzle

The tungsten carbide water jet cutting nozzle, also known as carbide nozzle water pipe, abrasive nozzle, water nozzle, water

knife, water knife sand tube, high pressure water knife sand tube, etc.

Mainly used for metal cutting, ceramic cutting, stone cutting, glass cutting and other material cutting.

Features:

1.100% raw material, can provide titanium telluride coating to increase wear resistance.

2. Specifications have Φ6.35, Φ7.14, Φ7.6, Φ9.45, etc.

3. Made of special materials, long service life, hardness up to 97.5, excellent wear resistance.

4. Sizes can be produced as required.

5. Factory’s offer

6. Strict products quality inspection

solution and high quality products for clients. We specialize in tungsten carbide rod, carbide plate&strips, carbide dies, carbide roller, carbide wear parts for petrochemical industry, carbide cutting tools.Tungsten carbide rod and customized wear parts is our advantage.

We always keep good relationship with our clients, enhancing communication

We are Factory with 13 years of production experience.

Q2: What is the producing process?

Production process including raw material cutting, machine processing, grinding, accessories cleaning, assemble, cleaning, stoving, oil coating, cover pressing, testing, package.

Q3: How to control the products quality?

Q4: What is the transportation?

If small quantity , we Suggest to send by express, such as DHL,UPS, TNT FEDEX. If large quantity, by sea.

Q5: Can you provide OEM service?

Yes, we work on OEM orders. Which means size, quantity, design, packing solution, etc will depend on your requests; and your logo will be customized on our products

Q6: How to place an order for Good performance nonstandard products by stellite alloy?

Q7: What’s your delivery time ?

For the normal type which we have mold it takes 7-15 days after receiving the advance payment. For the non standard which we do not have mold it takes 15-35 days after receiving the advance payment.

Q8:How to contact us?

You can Contact me by E-mail, Trademanager, Skype, Mobile, whatsapp and so on

If have any more information, please feel free to contact with me.

Contact person:Ms Sharon Chen

Email:sharon@chinahardalloy.com

Mobile phone:+86-18173388506

Website:www.wmcarbide.com

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com