Carbide Wear Parts

High quality tungsten carbide grinding bowl for chemical laboratory

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: K10,K20,K30

- Minimum Order Quantity:3 set

- Price:USD 730-1000/set

- Delivery Time:7-15 days

- Payment Terms:30% after confirming order the balance before shiping

- Supply Ability:10000 sets/month

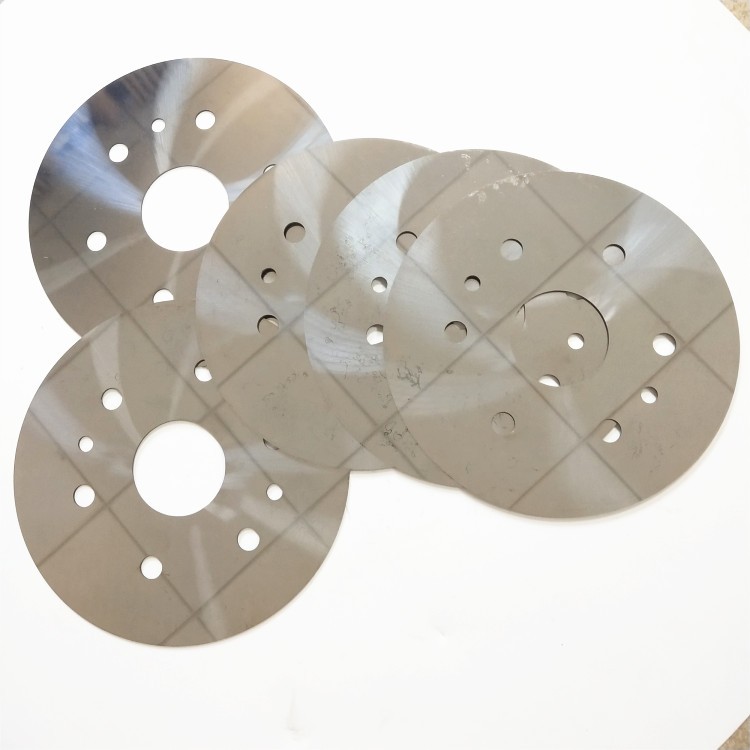

High quality tungsten carbide grinding bowl for chemical laboratory

Introduction of Tungsten Carbide Grinding Bowl

The production of Tungsten carbide mortar is very complex. The outside material generally is 45# steel, the inside lining is inlayed tungsten carbide material.

the mortar can grind very high hardness material becausethe high hardness of carbide material

Application fields:Iron,Aluminum,cobalt,plumbum,tungtsen,copper,tin,alumina,zirconia,silicon,carbon,etc.

Usage: Specimen-Making Machine

Main Material : Tungsten Carbide --YG15

Chemicial composition: WC85% Co14.5%

Physical Properties:Hardness: HRA87.5 Density:14.1g/cm3 T.R.S: 2080Mpa

Dimension:100g,200g,250g (can customized)

Temperature:-100~1000℃

Surface Treatment : finish/ground

We also can make manual mortar with grinding rod for University laboratory

Other grade of tungten carbide grinding mortar

| Grade | ISO | Density(g/cm3) | T.R.S(Mpa) | Hardness(HRA) |

| YG8 | K30 | 14.5 | 2000 | 89.5 |

| YG11C | K40 | 14.35 | 2200 | 88 |

| YG15 | K40 | 14 | 2500 | 87.5 |

| YG15C | K40 | 14 | 2700 | 86 |

| YG20 | K40 | 13.5 | 2750 | 84 |

| YG20C | K40 | 13.4 | 2800 | 82 |

Property of Zhenfang Tungsten Carbide Grinding Bowl

1.High wear resistance and toughness

2.High combination abilities

3.High impact-resistance

4. Long-lifetime

Our Advantage

1. 13year's manufacturing experience and advanced equipment guaranteed the stable quality and competitive price

2. 100% virgin raw material guaranted the long life time, good wear resistance and high impact-resistance

3. With strict quality control system: material incoming test-first samples test--production test-outgoing goods test etc. (hardness/ magnetic saturation/ density etc.)

4.. Fast delivery time

5. ISO-9001:2015 certificate

6. Standard and non-standard are all supported

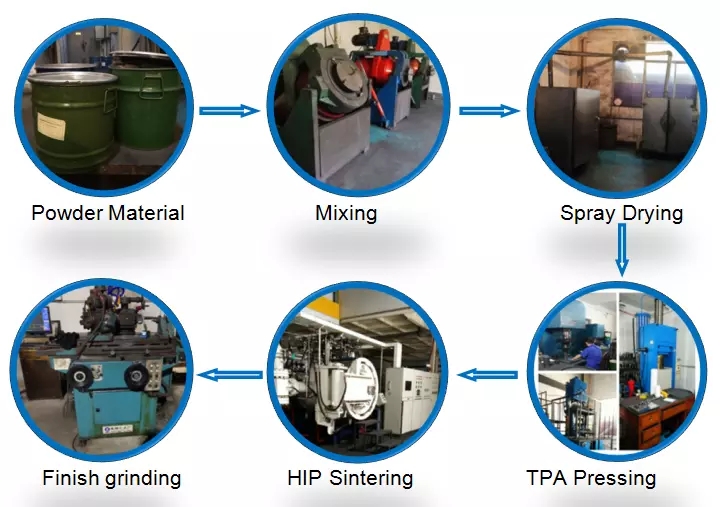

Production Process

Zhuzhou Zhenfang Yaguang Tungsten-Molybdenum Co.,LTD is a professional manufacture in tungsten carbide field. We have engaged in this field for over ten years. We have rich experience on tungsten carbide studying and manufacture.We pursuit providing efficient solution and high quality products for clients. We specialize in tungsten carbide rod, carbide plate&strips, carbide dies, carbide roller, carbide wear parts for petrochemical industry, carbide cutting tools. Tungsten carbide rod and customized wear parts is our advantage.

We always keep good relationship with our clients, enhancing communication and Cooperation to each other, trying to create WIN-WIN cooperation

1. Can I negotiate the Prices?

Yes.

2. What is your minimum order requirement?

We accept the sample and trial order.

3. How long will it take to execute my order?

For the stock items, we can arrange the shipment within 3-5 days after received your payment.

4. Can you give warranty of your products?

Yes, we extend a 100% satisfaction guarantee on all items. The detailed inspection pictures and the report of the order will be sent to you for confirmation before delivery. For the overseas orders, if there is quality problem, please kind to provide the pictures to show the problems by e-mail . We will provide the replacements to you at our cost according to actual conditions.

5. Can I visit you?

Sure, we have a showroom in our factory.

If you are intereested in us, please feel free to contact or visit us at any time.

Contact person:Ms Sharon Chen

Mobile phone:+86-18173388506

Email address:sharon@chinahardalloy.com

Website:www.wmcarbide.com

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 6A-block,Tianyikeji industrial park, Qunfeng town, Tianyuan district, Zhuzhou, Hunan, China 412000