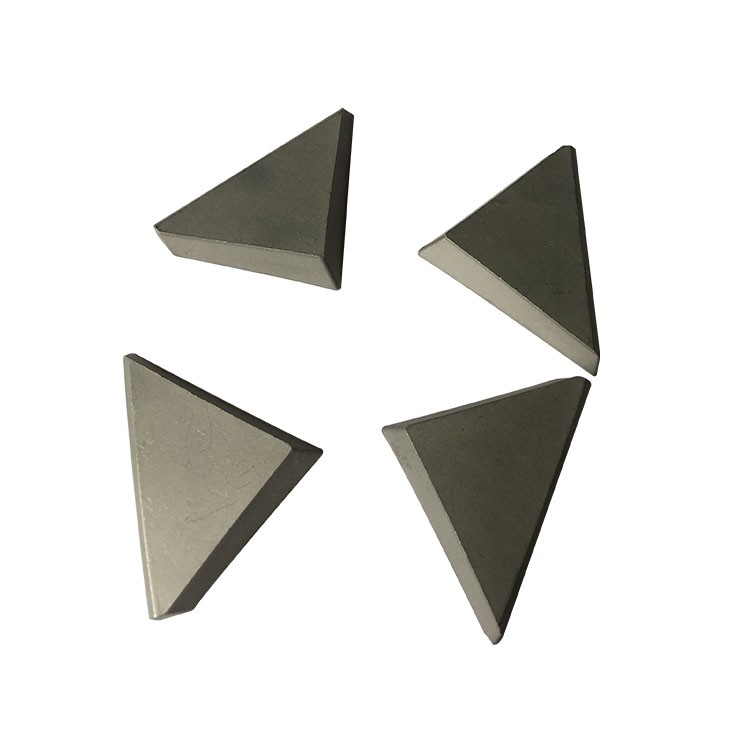

tungsten carbide blade

Tungsten carbide rolling cutter made by cemented carbide circular blade for fin machine

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF00158

- Price:Quote based on drawings

Tungsten carbide rolling cutter made by cemented carbide circular blade for fin machine

If have any more information, please feel free to contact with me.

Contact person:Ms Sharon Chen

Mobile phone:+86-18173388506

Email adddress:sharon@chinahardalloy.com

Website:www.wmcarbide.com

Detail Information

1. Material: 100%virgin WC+CO

2. Specification: OD140*ID40*1.1mm (various size)

3. Property: high abrasive resistance, good bending strength, good precision and flatness

4. Surface: high grinding, good flatness

5. Features: excellent cutting performance and long lifetime,

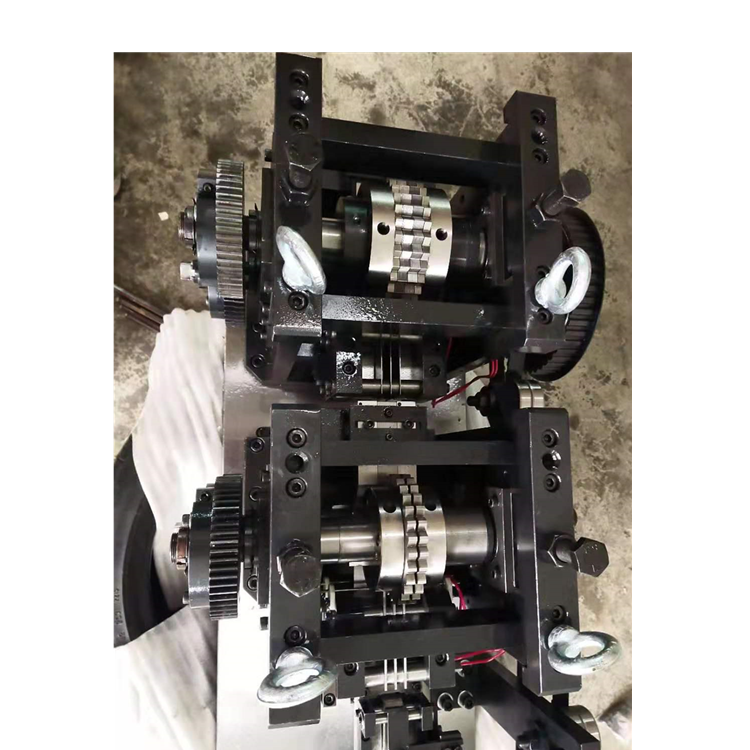

6. Application: Hobbing cutter of Fin Machine/heat exchanger

7. 100% inspection before shipment

8. Fast delivery time: 2 days for inventory, 15-18 dyas for mass manufacturing

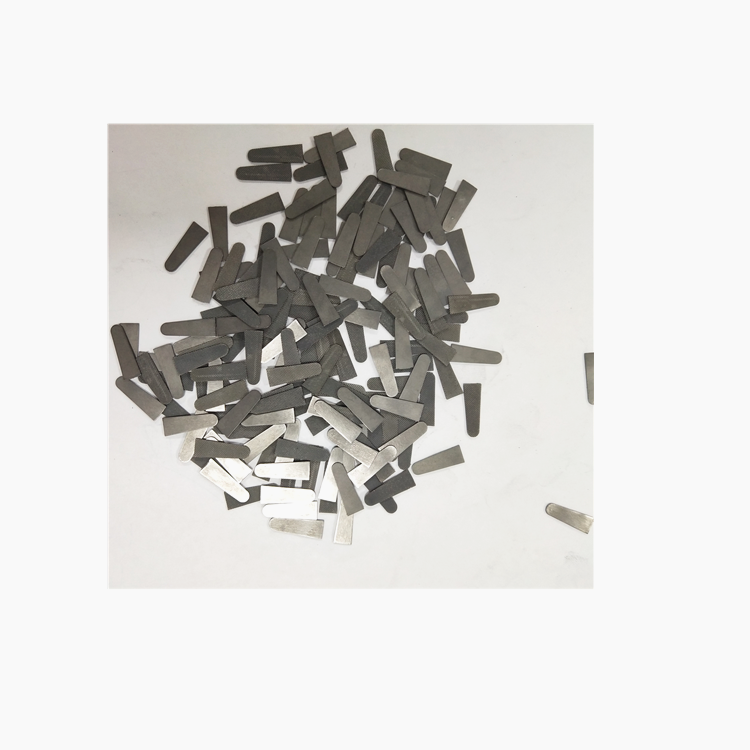

9. blank or finished also can be provided

Powder preparing-Pressing-Sintering-Processing- Finishing

1. Our products adopt spray drying tower granulation, raw material with low oxygen content, contamination,the flowability,

apparent density particle and granulate is uniform;

2. Adopting high-precision CIP molding machine, uniform product density, precise dimension,high roundness, and flatness;

3. Adopting advanced HIP sintering, effectively eliminate the internal holes and defects, the product has good compactness,

high strength, good polishing performance;

4. Adopting a special stress-relief process to eliminate the internal stress of products to further enhance the product

strength and improve the microstructure;

5. Precision grinding machine processing, ground rod can reach h6 tolerance.

With over 13 years experience in tungsten carbide manufascturing, our circular carbide blade for hobbing cutter have ecellent cutting performance. It is widely used in fin Machine. We got good feedback from our clients with fast cutting performance, good cutting precision,and long lifetime. It will bring great benefit for you.

Various dimension for reference(We can manufacture based on your drawing)

Our factory

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com