Tungsten Carbide Drill Blanks

Cheap Price Unground 10% Cobalt Solid Tungsten Carbide Drill Blanks Rod

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: YG10X YL10.2 YG12X

- Minimum Order Quantity:10 pcs

- Price:Negotiable

- Delivery Time:3-10days

- Payment Terms:L/C, D/A, D/P, T/T, Western Union

- Supply Ability:15tons/month

Zhuzhou Facory Unground 10% Cobalt Solid Tungsten Carbide Drill Blanks Rod

Zhuzhou Facory Unground 10% Cobalt Solid Tungsten Carbide Drill Blanks Rod

We manufacture unground carbide rods in stock with HIP and CIP sintered and 100% virgin material. Our grade include ISO K05 to K40, from machining carbon steel to aluminum , non-ferrous metals and titanium or we develop grade for your applications.

We recommended grade 10% cobalt covers a number of applications in cutting tools. The stability and high performance of the series bring many benefits to our customers and inspires them to develop quality products.

Solid tungsten carbide rods:

1. Grade: 10% cobalt and 12% cobalt recommend

2. Size: Diameter 1--30mm available

3. Certification: ISO9001,

4. Mirror polished to h6 and unground carbide rod are available

5. Each Metric and Inch dimensions available

6. Standard length: 330mm/310mm and can cut into different length as per requirments

Tungsten carbide solid round rod Features?

1. Excellent quality and competitive price

2. 100% raw material and recyle material as per your option

3. Good abrasion, heat and corrosion resistance

4. Various size and shape, grade

What's the Application?

1.Metal working, process into press tool, blade, cutter, wear parts, Blanks and polishing tungsten carbide plates for machinery lathe to machine HSS material,Alu ,steel,and stainless steel,etc.

2.Wood working,blanks and polishing solid tungsten carbide rods for wood working stone pit industry and mining industry.

3.Stone working,blank and polishing solid tungsten carbide rods for crusher machining of marble,granite,cobblestone,mountain stone,etc.

4.Other application,such as wear resistance parts of punching mold,measuring and cutting industry.

Recommended Grade:

| GRADE | GRAIN SIZE | COBALT | DENSITY | HRA | TRS |

| ZF10U | <=0.8um | 10% | 14.4 | >=91.3 | >=3600 |

| ZF10F | <=0.8um | 10% | 14.4 | >=91.5 | >=3800 |

| ZF12F | <=0.6um | 12% | 14.1 | >=92.5 | >=4000 |

Dimension and Tolerance:

| Dimension(mm) | Tolerance of diameter(mm) | Tolerance of length(mm) |

| Min BL-Φ1.0×330 | +0.20/+0.5 | -0/+5.0 |

| Max BL-Φ40×330 | +0.30/+0.8 | -0/+5.0 |

Our Guarantee

1. Competitive price , but good performance.

2. Press by CIP and Sintered in HIP furnace

3. Feedback within 24 hours. More details, please contact us skype/whatsapp: +86-13307338220

4. ISO9001: 2008 certificate professional manufacturer over 20 years

5. Fully adopted in advance technology and equipment.

6. Quality Control System and strict inspection.

7. OEM and ODM are accepted as well.

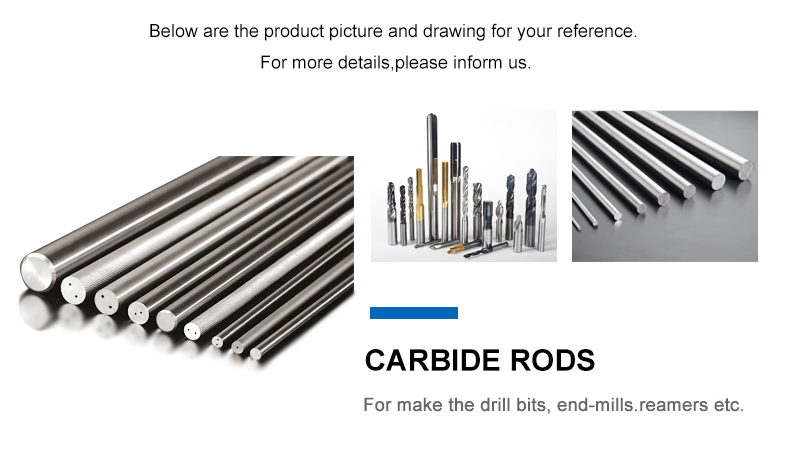

Tungsten Carbide Rods Types

For more information, warmly welcome to contact me

Ms. Shirley Pan

Email: shirley@chinahardalloy.com

Mobile: +8617773379950(wechat/whatsapp)

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 6A-block,Tianyikeji industrial park, Qunfeng town, Tianyuan district, Zhuzhou, Hunan, China 412000