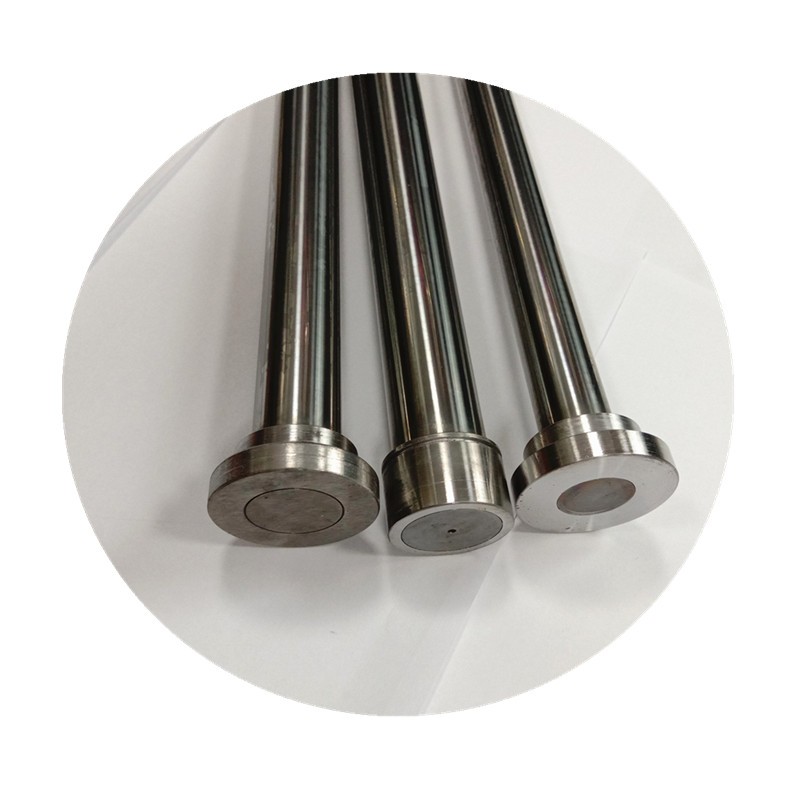

Plunger

Pressure Pump Non Magnetic Cemented Carbide(WC)Plunger Piston

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF-P027

- Minimum Order Quantity:3pcs

- Price:Negotiable

- Delivery Time:3-18days

- Payment Terms:L/C, D/A, D/P, T/T, Western Union

- Supply Ability:15tons/month

For more information, warmly welcome to contact me

Shirley Pan(Ms)

Email:shirley@chinahardalloy.com

Mobile:+8617773379950

Pressure Pump Non Magnetic Cemented Carbide(WC)Plunger Piston

Application Range:

our tungsten carbide plunger widely used in high pressure pump, high pressure cleaning pump, High-power high-pressure pump group, High Pressure Pump Automatic Set,Pipe dredge, High-pressure oil injection machinery etc.

Detail Information

1. Material: WC+Ni/WC+Co

Our advantage:

1. Material: using high quality raw material

2. Production Procedure: Powder preparing- Pressing-HIP sintering- Processing-Finishing

3. Perfect quality control systerm: ISO9001:2015

4. Various dimension for choosing

5. Various grade for choosing based on your application. the hardness is from HRA82 to HRA92.5

6. We also accept manufacturing based on your drawing

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

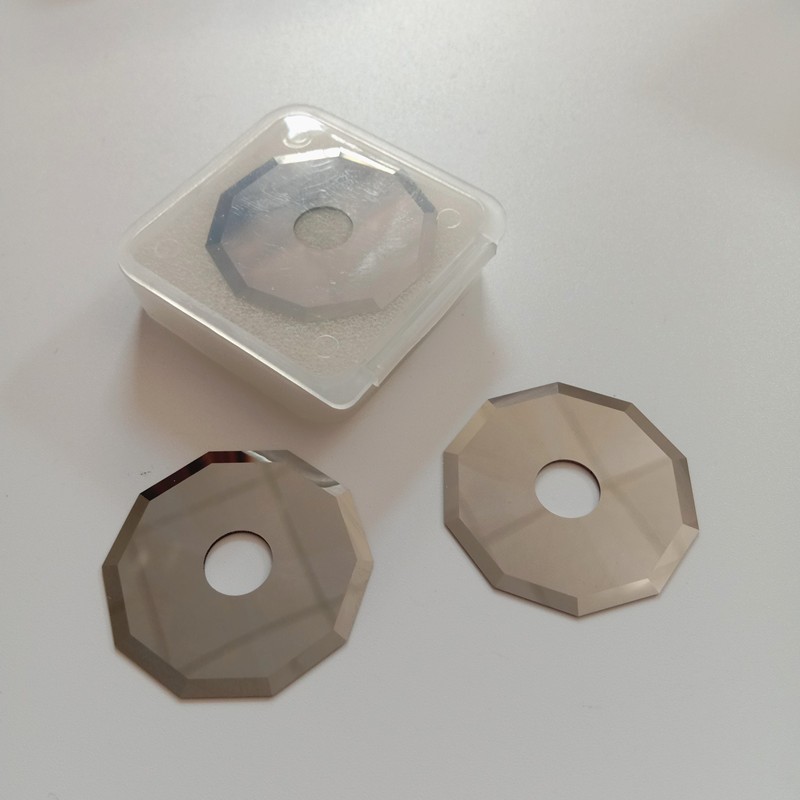

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 6A-block,Tianyikeji industrial park, Qunfeng town, Tianyuan district, Zhuzhou, Hunan, China 412000