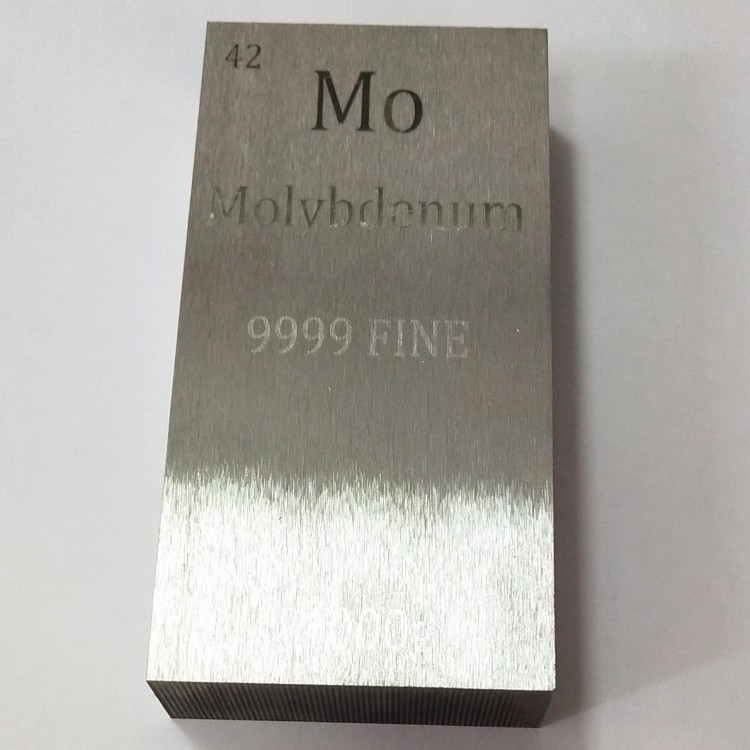

Molybdenum Products

99.95% High purity molybdenum rod electrode processing

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF0096

- Minimum Order Quantity:100 pcs

- Price:USD 55-65/kg

- Delivery Time:7-15 days

- Payment Terms:100% TT before shiping

- Supply Ability:100000 pcs/month

99.95% High purity molybdenum rod electrode processing

purity | 99.95% min |

Size | dia(0.08-100)*L mm |

Surface | black, ground, polished |

Density | 10.2g/cc |

Appearance | rolling rods: Dark brown, the surface is smooth and straight, no defects (crackle, heavy skin, hole, trough, etc) ; |

Electrode rods | Bright silver gray metallic luster. (process according to user's drawing, surface finish is higher) |

Features and application

Molybdenum bar have high melting point, good thermal conductivity and low thermal expansion performance, under the environment of high temperature, it have good oxidation resistance and high strength.

Generally used in the manufacture of electric vacuum device and electric light source parts, suit for ion implantation parts.

Used as high temperature heating element and high temperature furnace internal parts.

Used as melting pot electrode in the glass and refractory fiber industry.

Used as electrode in the rare earth industry.

Used in the production of molybdenum wire.

Used in the production of molybdenum crucible.

Product advantage:

Molybdenum Electrode Introduction:

Molybdenum electrodes are made through isostatic pressing and can be forged to various specifications after undergoing sintering and shaping in medium frequency furnaces. Glass melting electrodes must with stand extremely high temperatures and aggressive glass melts. Molybdenum is the right material for these challenging conditions.

Our more Products

1. Tungsten Carbide rod

2. Tungsten Carbide Sealed Ring

3. Tugnsten Carbide Wear parts

4. Tugnsten Carbide Dies

5. Tungsten Carbide Non-standard parts

6. Tungsten Carbide Circular Blade

Why choose us ?

1. We are a real factory with very very nice wholesale price with high quality and good after sales service.

2. Rearch and development team with 5 members is rich experienced. OEM and label printing

orders are welcome.

3. The MOQ is 1pc.Sample and freight fee is borne by buyer.The sample fee will be reduced in

the next big quantity order.

4. Quick delivery time. We have carbide rods in stock. Delivery time within 3 days after your payment.If quantity is customized and large,delivery time is negociate.

If have any more doubt, please feel free to contact with me.

Contact person:Ms Sharon Chen

Email:sharon@chinahardalloy.com

mobile phone:+86-18173388506

website:www.tungstencarbide-rods.com

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 6A-block,Tianyikeji industrial park, Qunfeng town, Tianyuan district, Zhuzhou, Hunan, China 412000