Custom Tungsten Carbide Parts

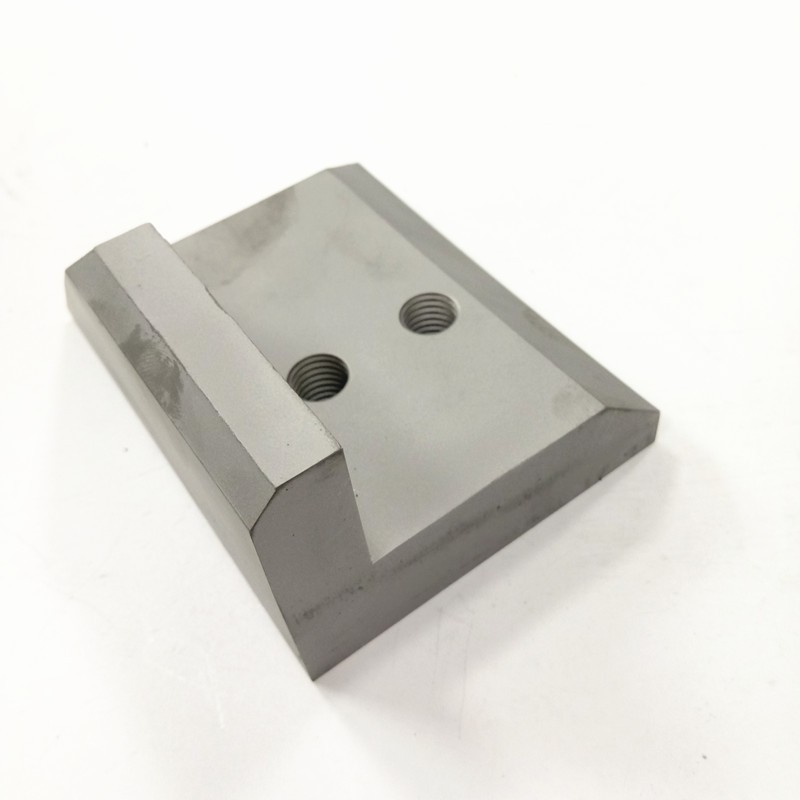

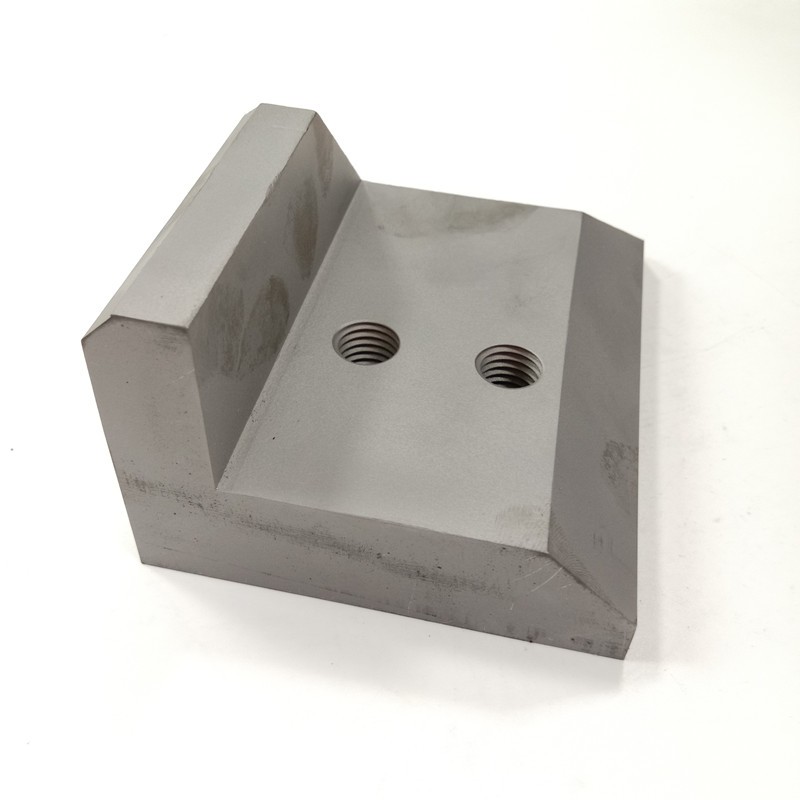

Customized Cemented Tungsten Carbide Wear Part With Inner Screw

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: K10 K20 K30 YL10.2 YN8 YN9

- Minimum Order Quantity:10 pcs

- Price:Negotiable

- Delivery Time:3-15days

- Payment Terms:L/C, D/A, D/P, T/T, Western Union

- Supply Ability:15tons/month

For more information, wearmly welcome to contact me

Shirley Pan

Email:shirley@chinahardalloy.com

Mobile: +86 17773379950

Customized Cemented Tungsten Carbide Wear Part With Inner Screw

Our main products include tungsten carbide inserts, mining tips, indexable insert shims, drilling bits, cutter tips, drawing dies, cold forging dies, carbide bars, rods, balls, wear parts, etc.

Our company can also manufacture various cemented carbide tools as per drawings and samples based on different requirements of customers and provide a whole package of solutions for mechanical machining and manufacturing.

A. Detail Information

1.Product Name: Non standard Tugnsten Carbide Wear Parts In China

2.Material: WC+CO

3. Surface: Rough Machine

4. Size: Manufacture following drawing

5. Certificate: ISO9001:2015

6. Features: Excellent Abrasive Resistance

7. Grade: YG6/YG8/YL10.2/YG6X

8. Application: Wear Parts on Mechanical equipment, mould

Main Grade and Application (other grades can be offered by customer's requirements)

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 7 buildings in area C, High-tech Auto parts City, Zhongda Road, Tianyuan District, Zhuzhou City, Hunan Province.