Custom Tungsten Carbide Parts

high precision tungsten carbide roller for cold /hot rolling mill

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF0058

- Minimum Order Quantity:10 pcs

- Price:USD 55-65/kg

- Delivery Time:7-15 days

- Payment Terms:100% TT before shiping

- Supply Ability:100000 pcs/month

high precision tungsten carbide roller for cold /hot rolling mill

Detail information

1. Material: good quality WC+Co+Ni+Cr

2. Grade: YGR20 Hardness:HRA87.2

3. Size: OD180*ID125*100mm (various size)

Grade as following :

YG6,YG6X,YG8,YG8.2,YG8L,YG15,YG20,YG20C,YG20D etc are the traditional material,suitable for the normal tungsten carbide ring

Specifications:

1.ISO9001:2015 Certificate

2.Material in Fine Grain Size

3.Direct sale from our own factory

Our rolls include PR,CA,RT, RO,FO type. Also we could make it as per customer requirements.

The material of rolls blanks we used are sintered in HIP furnace, 100% virgin material of Tungsten Carbide.

Package:

Wooden box. The package of Tungsten carbide roller with good wear resistance are available based on customers' requirements.

We can offer various grade and size based on your application and requirement

Introduction of cemented carbide roller:

Cemented carbide roller used on the stretch reducing mill for bars, thread steel bars and common wire with the durability 10 to 20 times higher compared to common steel roller. The surface quality and the steel bar size accuracy are greatly improved. The cemented carbide roller reduces effectively the production cost and improves the quality.

Advantages of our cemented carbide roller :

1. 10 - 20 times life time longer than steel roller. Saving maintenance time and cost.

2. Improved mechanical properties.

3. Good surface finish and corrosion-resistance.

4. V – U and custom straightening grooves.

Roller for Profile Wire Rolling, Flat Wire Rolling, Construction Wire Rolling, Plain Wire Rolling and Welding Wire Rolling, Wire Straightening, Wire Guiding etc.

Carbide descaling roller

Carbide reliving roller

Carbide straightening roller

Carbide guide roller

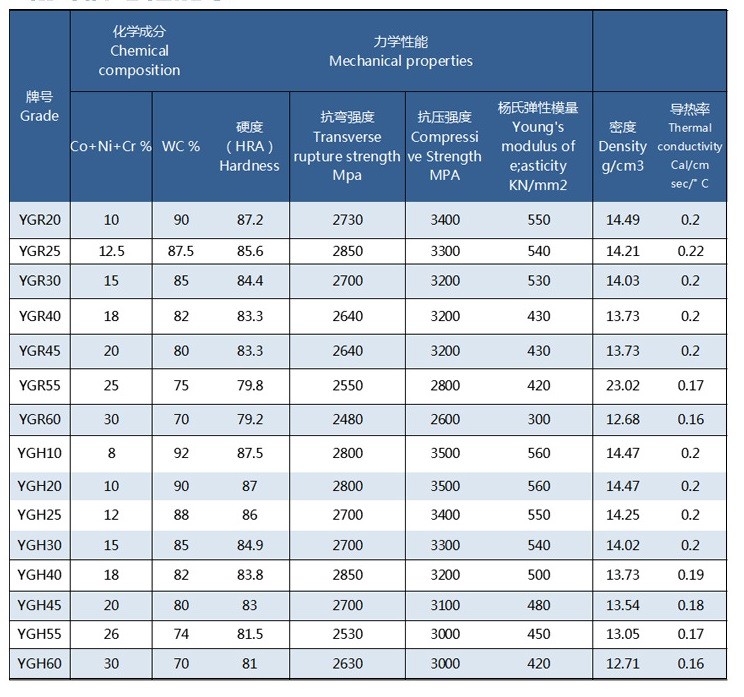

Some Grade Information

Zhuzhou Zhenfang Yaguang Tungsten-Molybdenum Co.,LTD is a professional manufacture in tungsten carbide field. We have engaged in this field for over ten years. We have rich experience on tungsten carbide studying and manufacture.We pursuit providing efficient solution and high quality products for clients. We specialize in tungsten carbide rod, carbide plate&strips, carbide dies, carbide roller, carbide wear parts for petrochemical industry, carbide cutting tools.Tungsten carbide rod and customized wear parts is our advantage.

We always keep good relationship with our clients, enhancing communication and Cooperation to each other, trying to create WIN-WIN cooperation

OEM, ODM service

Distributor discounts

Sample order be accepted

After-sale service: Replacement, refund

Technical support: Installation, analysis production condition

Fast Delivery Competitive price

If you are interested in our products, please feel free to contact us at any time

Contact person:Ms Sharon Chen

Mobile phone:+86-18173388506

Email address:sharon@chinahardalloy.com

Website:www.tungstencarbide-rods.com

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 7 buildings in area C, High-tech Auto parts City, Zhongda Road, Tianyuan District, Zhuzhou City, Hunan Province.