Carbide Wear Parts

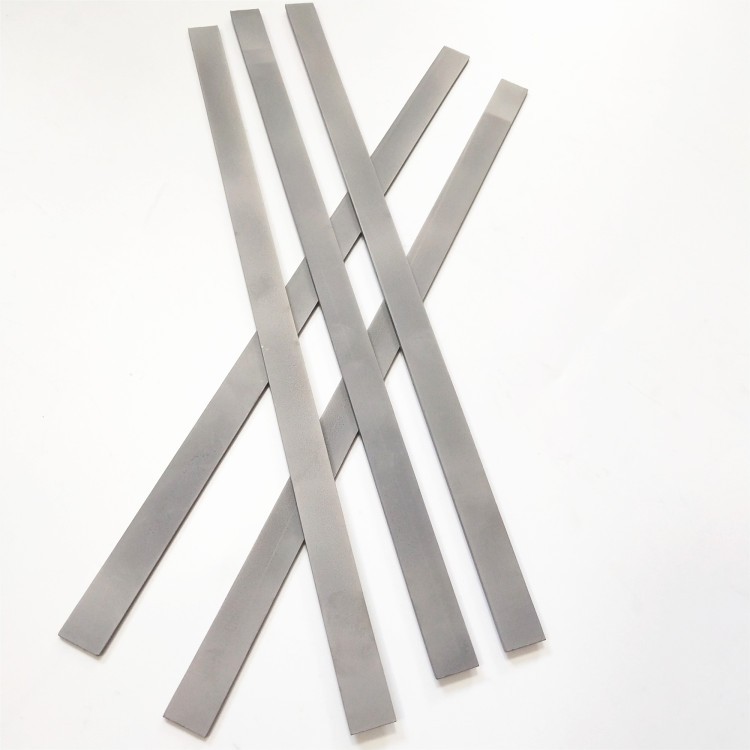

China high bending strength tungsten carbide wear plate/ cemented carbide strip manufacturer

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: YG10X, YL10.2, YG12X, YG15X etc

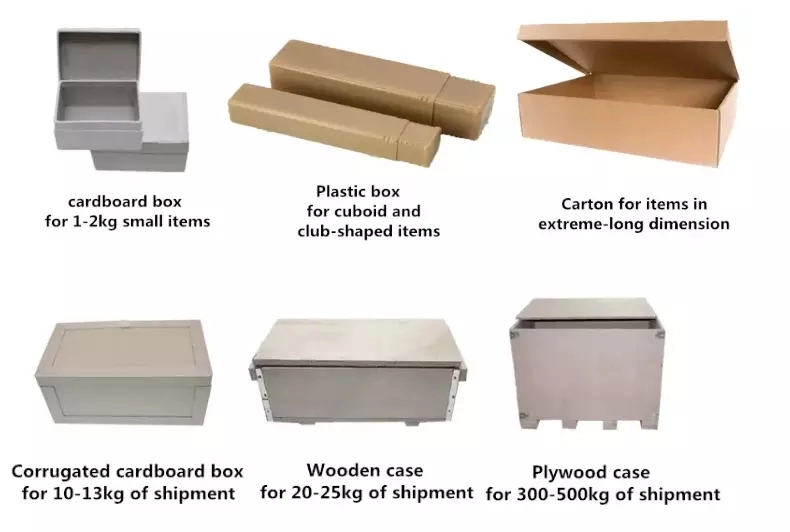

- Minimum Order Quantity:100 pcs

- Price:USD 45-58/kg

- Delivery Time:3-5 days

- Payment Terms:30% after confirming order the balance before shiping

- Supply Ability:100000 pcs/month

China high bending strength tungsten carbide wear plate/ cemented carbide strip manufacturer

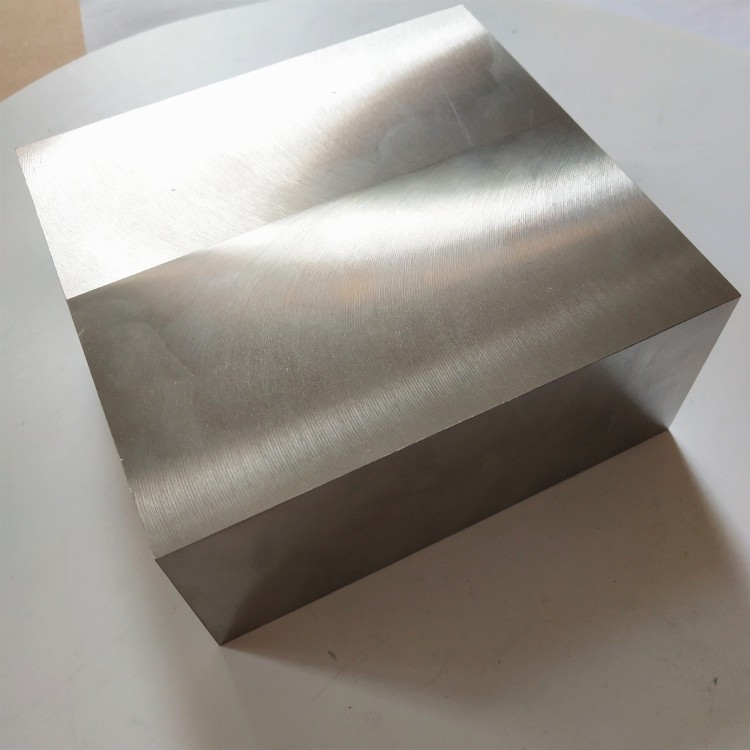

The carbide strips are used in wide application field. They’re very good material to produce the parts to resist high temperature & corrosion, also widely used as wear parts, shielding parts, mold core, insert, special shape punch and so on, for cutting cast iron, nonferrous metals, plastics, chemical fiber, stainless steel and high Manganese steel, etc.

Various grades and sizes can be chosen.

Features:

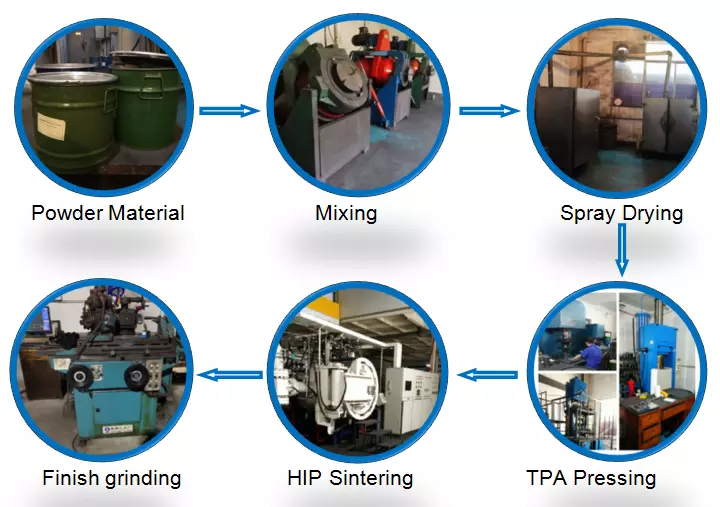

1. 100% virgin raw material

2. High hardness, excellent wear-resistance

3. High elastic modulus and compressive strength

4. Stable chemical properties

5. Blanks, precision grinded and polished

6. Various sizes and grades

7. Factory’s offer

8. Strict products quality inspection

Length(mm) | Width(mm) | Thickness(mm) |

10-330 | 2-100 | 1.2-20 |

Tungsten carbide strips are usually used for treating solid wood, shaving board and middle-density fiberboard,Also be used to make woodworking tools, such as forming tool, reamer, serrated knife blade and various blade,our strips meet the ISO 9001:2015 quality standard.

Mainly used in vertical shaft impact crusher (sand making machine), with high performance and high efficiency of sand making and shaping. A variety of crushing forms (stone-to-stone, stone-to-iron) to meet different crushing needs of users. Rotor with stone-stone structure-suitable for crushing sand for hard and extremely hard materials, and shaping various soft and hard materials.

It can adjust the level of stone powder content, which is suitable for the requirements of high stone powder content in grinding jade concrete, and the requirements of low stone powder content for ordinary concrete. The stone iron rotor is used-suitable for the crushing of materials below medium hardness, with high crushing efficiency, Features such as high sand production rate and easy adjustment of fineness modulus.

1. Adapt to different material crushing requirements of users. Such as: granite, basalt, limestone, quartzite, gneiss, cement

clinker, concrete aggregate, ceramic raw materials, iron ore, gold ore, copper ore, corundum, bauxite, silica, etc.

2. Compared with other materials, it has the advantages of good comprehensive performance, high reliability, strong wear

resistance, and low price!

3. The length of the alloy bar can be customized according to the specifications of the throwing head, and the service life of each pair of alloys can reach 40-70 hours.

1. Tungsten Carbide rod

2. Tungsten Carbide Sealed Ring

3. Tugnsten Carbide Wear parts

4. Tugnsten Carbide Dies

5. Tungsten Carbide Non-standard parts

6. Tungsten Carbide Circular Blade

If have any more information, please feel free to contact with me.

Contact information

contact person: Ms Sharon Chen

mobile number +86 18173388506

email address: sharon@chinahardalloy.com

Website:www.wmcarbide.com

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 6A-block,Tianyikeji industrial park, Qunfeng town, Tianyuan district, Zhuzhou, Hunan, China 412000