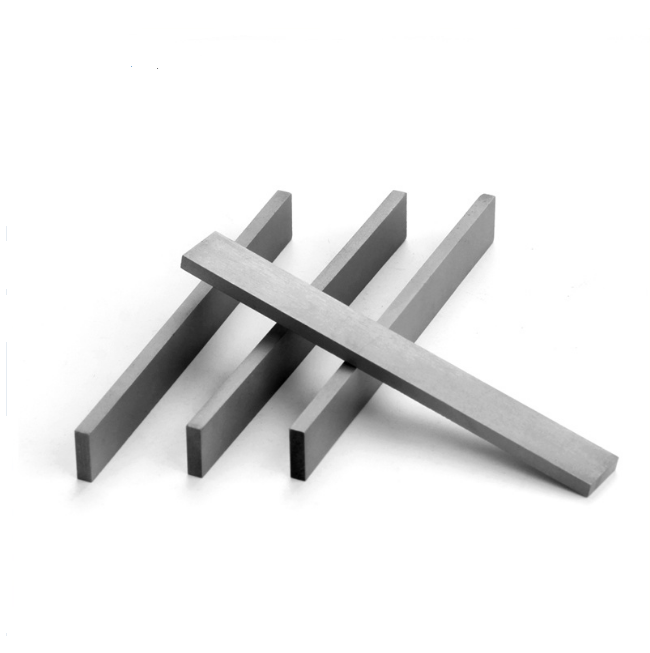

Carbide Wear Parts

Tungsten carbide pins,cemented carbide welding inserts,brazed carbide tips for safety hammer

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: YG10X, YL10.2, YG12X, YG15X etc

- Minimum Order Quantity:1000 pcs

- Price:USD 45-58/kg

- Delivery Time:3-5 days

- Payment Terms:30% after confirming order the balance before shiping

- Supply Ability:100000 pcs/month

Tungsten carbide pins,cemented carbide welding inserts,brazed carbide tips for safety hammer

We are Professional Mufacture in China that mainly produce Tungsten carbide pins,cemented carbide welding inserts,brazed Carbide tips, For various types and specification. This like for making core clampers for lathes and periphery grinders.We also acceptable customize inserts carbide tips,pins,inserts as customer requirement!

-Zhenfang Cemented Carbide always with the best quality and well-known in ZhuZhou Carbide Base.

-Zhenfang Carbide with good abrasive resistance and resistance to cracking!

1).hot selling:tungsten carbide pins,cemented carbide welding inserts,brazed carbide tips;

2).Grade:YG6X(K10)/YG6(K20)/YG8(K30);

3).Application field: for making core clampers for lathes and periphery grinders;

4).Free samples available;

5).MOQ:1pcs;

6).Detail pictures show to you:

-Based on our experience, We recommend Grade materials for Carbide tips,inserts,pins as below:

YG6X(K10)/YG6(K20)/YG8(K30)

| Grade | ISO | Density g/cm3 | Hardness HRA> | T.R.S>N/mm² | Performances or recommended applications | |||||

| Grade | ||||||||||

| Conventional grades | ||||||||||

| YG3 | K05 | 15.20-15.40 | 91.5 | 1400 | Medium grain, for finishing machining of cast iron and non-ferrous metals | |||||

| YG3X | K05 | 15.20-15.40 | 92 | 1300 | Fine grain, for finishing machining of cast iron and non-ferrous metals | |||||

| YG4C | 15.05-15.25 | 90 | 1620 | Coarse grain, for percussion drill bits and mining inserts | ||||||

| YG6 | K20 | 14.85-15.05 | 90.5 | 1860 | Medium grain, for rough machining of non-ferrous metals | |||||

| YG6A | K10 | 14.85-15.05 | 92 | 1600 | Fine grain, for drawing dies and woodworking tools | |||||

| YG6X | K10 | 14.85-15.05 | 91.7 | 1800 | Fine grain, for cutting of non-ferrous metals | |||||

| YG7 | K20 | 14.65-14.85 | 90 | 1900 | Medium grain with good wear-resistance and good impact- resistance | |||||

| YG8 | K30 | 14.60-14.85 | 89.7 | 2060 | Medium grain, for drawing dies | |||||

| YG8A | K30 | 14.6-14.85 | 90 | 2000 | Medium grain, for the drawing dies and wood-working | |||||

| YG8X | K30 | 14.60-14.85 | 90.5 | 2000 | Fine grain, high hardness and oxidation resistance at high temperatures and good impact toughness | |||||

| YG8C | 14.55-14.75 | 88 | 2160 | Coarse grain, for button drill bits and the mining inserts | ||||||

| YG10 | K40 | 14.25-14.55 | 88 | 2160 | Medium grain, for machining gray cast iron with a low hardness | |||||

| YG11 | K40 | 14.30-14.50 | 87.5 | 2260 | Medium grain, for wear parts and mining tools | |||||

| YG11C | 14.20-14.40 | 87 | 2260 | Coarse grain, for mining inserts | ||||||

| YG12 | K40 | 14.10-14.40 | 87 | 2260 | Medium grain, for rough machining of non-ferrous metals | |||||

| YG15 | 13.95-14.15 | 86.5 | 2400 | Medium grain, for mining tools, cold heading and punching dies | ||||||

| YG20 | 13.45-13.65 | 84 | 2480 | Medium grain, for non-standard dies and moulds, cold heading and punching dies | ||||||

| YG20C | 13.40-13.60 | 82.5 | 2480 | Coarse grain, for die and moulds making screws of a diameter of 20-50mm | ||||||

| YG22 | 13.15-13.55 | 83 | 2480 | Medium grain, for non-standard dies and moulds, cold heading and punching dies | ||||||

| High-performance grade | ||||||||||

| YD40 | 13.10-13.55 | 82.5 | 2480 | High impact resistance, for cold heading and punching dies and hot heading and punching dies | ||||||

| YD45 | 13.25-13.65 | 83 | 2480 | High impact resistance, a special grade for hot heading dies | ||||||

| YG011 | K10 | 14.55-14.75 | 92.5 | 1840 | Ultra-fine grain size, for machining glass fiber reinforced plastics, titanium alloys, hardened steel with a high hardness | |||||

| YG012 | K20 | 14.25-14.55 | 91 | 2160 | Ultra-fine grain, for milling cutters and the hole-machining tools | |||||

| YG013 | K10 | 14.35-14.60 | 91.5 | 2060 | Ultra-fine grain with good wear resistance and toughness, for wood-working tools | |||||

| YG014 | K05 | 14.65-14.95 | 93 | 1760 | Ultra-fine grain, for finishing machining of non-ferrous metals and for wood-working tools | |||||

| Cutting steel class grade | ||||||||||

| YT03 | P10 | 14.75-14.95 | 91.5 | 1860 | Suitable for the semi-finishing and finishing machining of non-ferrous metals, stainless steel | |||||

| YT5 | P30 | 11.50-13.20 | 90 | 1750 | Suitable for heavy duty cutting of steel and cast steel and for a low-speed and medium-speed and a big feed-rate roughing operation under unfavorable machining conditions | |||||

| YT14 | P20 | 11.20-11.80 | 91 | 1550 | Suitable for semi-finishing and finishing machining of steel and cast steel, using a medium feed-rate | |||||

| YT15 | P10 | 11.10-11.60 | 91.5 | 1500 | Suitable for semi-finishing and finishing machining of steel and cast steel and a medium feed-rate and a rather high cutting speed is to be recommended | |||||

| YS25 | P25 | 12.80-13.20 | 91 | 1860 | A special grade for mining steel and cast steel | |||||

| SC30 | P30 | 12.70-13.20 | 90 | 1600 | Suitable for heavy duty cutting of steel and cast steel with a possible big feed-rate | |||||

| YC40 | P40 | 13.00-13.40 | 89.5 | 1860 | Suitable for heavy duty cutting of steel and cast steel with a possible big feed-rate and for face milling as well | |||||

| YW1 | M10 | 12.85-13.40 | 92 | 1380 | Suitable for semi-finishing and finishing of stainless and ordinary alloyed steel | |||||

| YW2 | M20 | 12.65-13.35 | 91 | 1680 | Suitable for semi-finishing and finishing of stainless and low alloyed steel, mainly used for machining of trains' wheel hubs | |||||

| YW3 | M10 | 12.85-13.10 | 92 | 1420 | It is suitable for semi-finishing and finishing of stainless and ordinary alloyed steel | |||||

Assembling On Tool Bit, Engraving or Scribing On Very Hard Items, For Example: Aluminum, Brass, Bronze, Metals, Steel, Glass, Ceramics, Hardwood, Etcs.

Our advantage of tungsten carbide pin

* ISO 9001:2015 Certification

* Use 100% tungsten carbide raw material

* Advanced technology , automatic pressing , HIP sintering

* with over ten year experience

* And precision grinding

* the tolerance of polish and ground can be +0.005/-0.005mm

* Full ability to accept OEM & ODM orders

* Stringent quality control and quality consistency.

* Strict inspection for quality of raw material and finished products

We Guarantee:

1. produced with advanced equipments and process.

2. high quality durable tungsten carbide rod blanks/cemented rods for milling for router bits made from 100% virgin raw material.

3. all products go through in-process and final inspection.

4. Quality Control System and strict inspection.

5. stable and continuous production ability.

6. free online technical service available.

7. OEM and ODM are accepted as well.

8. Our solid carbide rods are known for constantly providing maximum quality. You can rely on our products as a basis for

consistent performance capacity of your tools.

9. Undertake orders of non-standard sizes at customer's requests.

We can offer a lot of type tungsten carbide rods:

1. un-gound, finish-ground in metric and imperial diameters;2. Carbide rods with central coolant duct;

3. Fixed length Carbide Rod

4. Random Length carbide rod

5. Carbide rods with chamfered end.

If have any more information, please feel free to contact with me.

Contact person:Ms Sharon Chen

Email:sharon@chinahardalloy.com

Mobile phone:+86-18173388506

Website:www.wmcarbide.com

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 6A-block,Tianyikeji industrial park, Qunfeng town, Tianyuan district, Zhuzhou, Hunan, China 412000