Tungsten Products

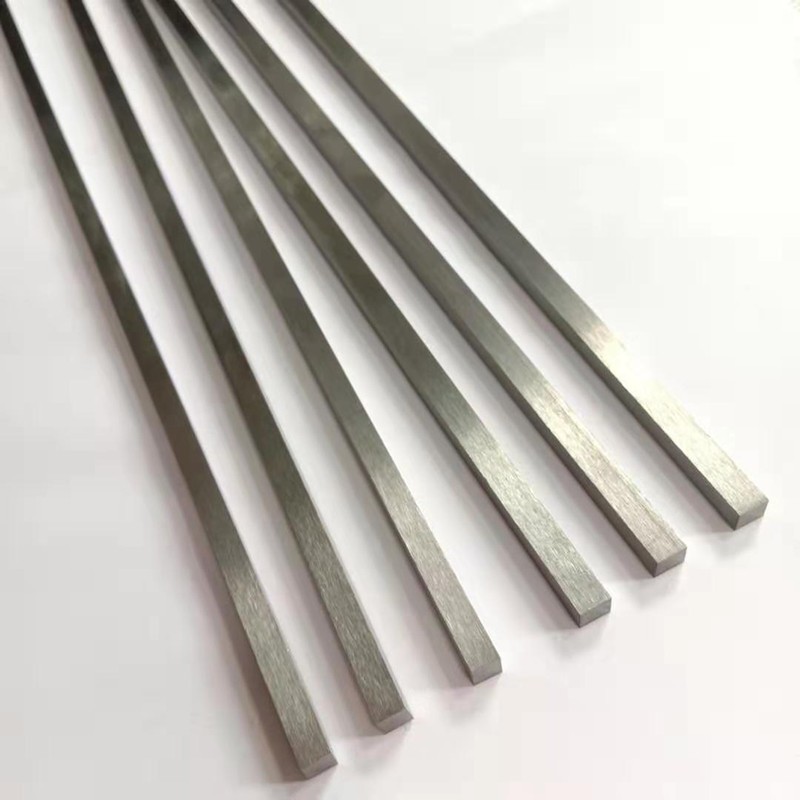

10*10*300mm Tungsten Square Bar Purity 99.95% For Electrode / Heat Shield

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF-T058

- Minimum Order Quantity:10 pcs

- Price:negotiable

- Delivery Time:3-18days

- Payment Terms:L/C, D/A, D/P, T/T, Western Union

- Supply Ability:15tons/month

For more information, warmly welcome to contact me

Shirley Pan(Ms.)

Email: shirley@chinahardalloy.com

Mobile:+8617773379950

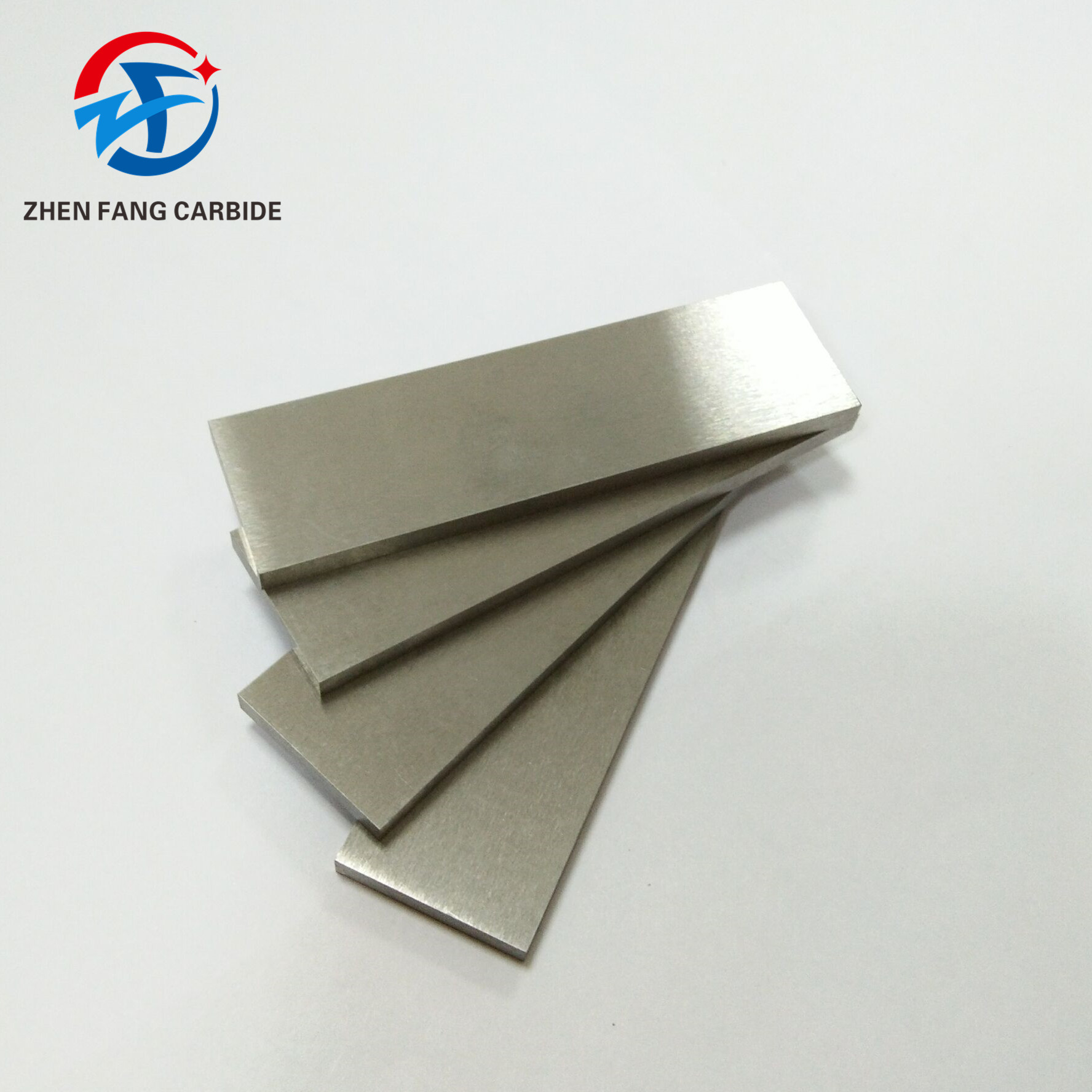

10*10*300mm Tungsten Bar, Tungsten Sheet For Electrode 99.95% Purity

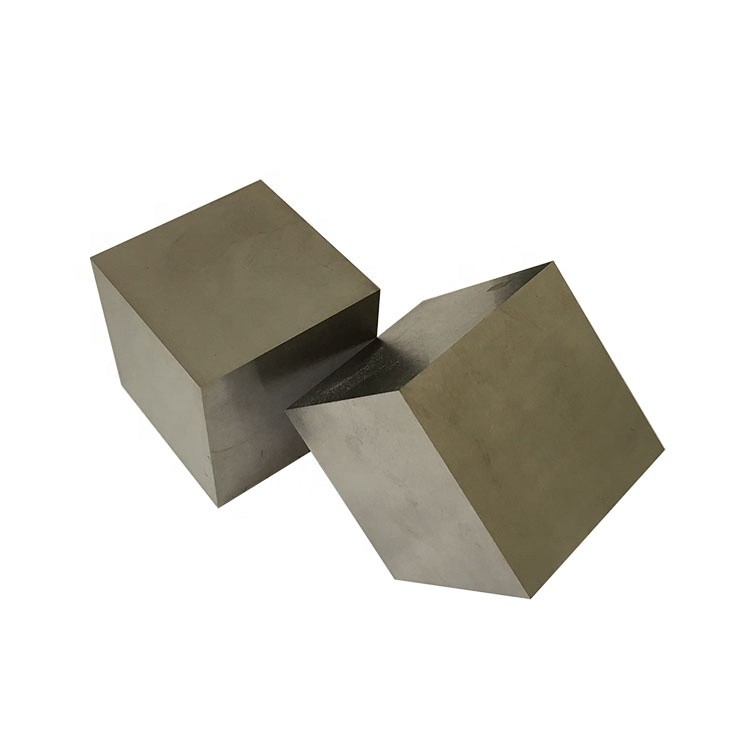

| Name | Tungsten bar ,tungsten sheet |

| Purity | 99.95% |

| Density | 19.3g/cm3 |

| Melting point | 3620℃ |

| color | Grey sliver |

| size | customized |

| standard | ASTM B760-07 |

| Grade | w1,w2 |

| Surface | sintered / forging/Rotary forging/ rolling/ grinding |

| Packaging | Standard wooden package |

| Application | Industrial, medical, metallurgy etc |

Application:

1. Tungsten plates are used for producing tungsten electrodes, heating elements, heat shields, sintering trays, sintering boats, stacking sheets, base plates, sputtering targets, crucibles in electronic and vacuum applications;

2. Tungsten plate is basically used in the technology of coating manufacturing and chemical vapor deposition (CVD) and physical vapor deposition (PVD) of thin film, including heat and electron beam evaporation, low temperature organic evaporation, atomic layer deposition (ALD), specific application of metal organic chemical vapor deposition (MOCVD);

3. Tungsten plate is widely used in rotating anode X ray tube, heating elements in high temperature furnace, reflection shield, sapphire growth furnace, high temperature tape, insulation screen, vacuum coating equipment and the shield of high temperature resistance ship.

Features:

1. Tungsten plate has the highest melting point and boiling point among all metals;

2. Three methods of producing tungsten plate include hot rolling process, warm rolling process and the cold rolling process. And tungsten plate production process involves stamping, spinning and drawing;

3. Tungsten plate is of high density, internal structure stability, resistance to high temperature;

4. We can produce tungsten plate with matte surface or glossy surface according to different materials' thickness, width and rolling process5; The purity of the tungsten plate can reach 99.97% and density 18.8-19.1g/cm3;

5. Tungsten plate from Achemetal is under vacuum annealing and leveling before delivery;

6. Our tungsten plate is approved by ASTM B 386-2003 and GB 3876-2007 and GB 3877-2006;

7. We can produce tungsten plate with matte surface or glossy surface according to different materials' thickness, width and rolling process.

Parameters of Tungsten Plate:

| Thickness (mm) | Width (mm) | Length (mm) |

| 1.5-2.0 | 150 | 200 |

| 2.0-3.0 | 200 | 250 |

| 3.0-4.0 | 250 | 600 |

| 4.0-6.0 | 300 | 600 |

| 6.0-8.0 | 300 | 600 |

| 8.0-10.0 | 300 | 750 |

| 10.0-14.0 | 200 | 650 |

| 14.0 - | 250 | 500 |

Parameters of Tungsten Square Plate:

| Thickness (mm) | Width (mm) | Length (mm) |

| 1.0-5.0 | 500 | 500 |

| 6.0-10.0 | 400 | 400 |

| 10.0-14.0 | 350 | 350 |

| 14.0- | 300 | 300 |

Our company can also provide tungsten plates according to customers' requirements.

1. Carton with water proof paper and protective foam inside

2. Standard wooden case

Our Service

1. Prompt response within 24 hours after receving your inquiry.

2. Experienced people do the right thing for your order.

3. Payment term could be negotiated.

4. Quality could be guaranteed, because the materials is from our reliable partners who is in this field more than 10 years.

5. On-time delivery: We ensure that your goods can be completed within 20 days once got the down payment.

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 7 buildings in area C, High-tech Auto parts City, Zhongda Road, Tianyuan District, Zhuzhou City, Hunan Province.