Carbide Wear Parts

High pressure resistance shaft sleeve tungsten carbide bushing for petroleum chemical industrial

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: YG6,YG8

- Price:Quote based on drawings

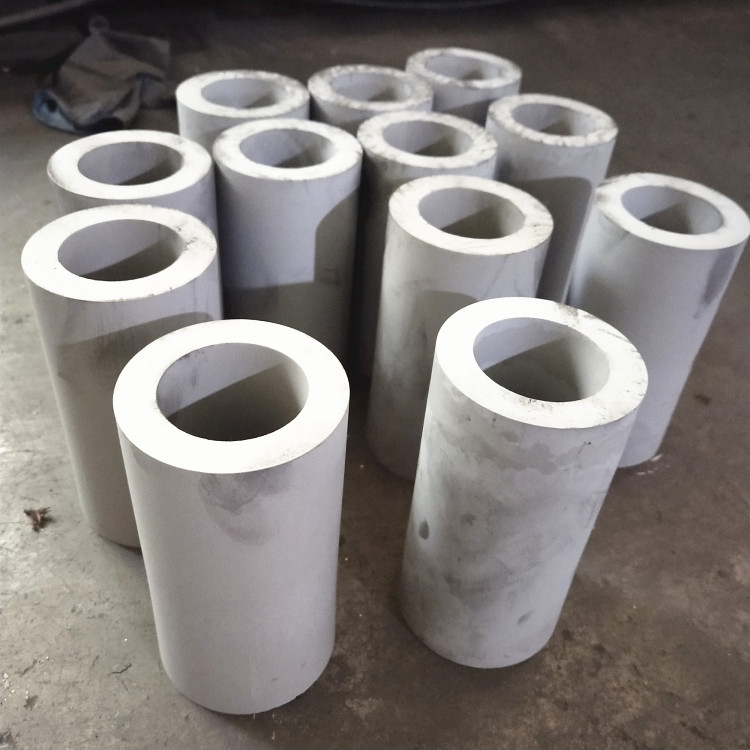

High pressure resistance shaft sleeve tungsten carbide bushing for petroleum chemical industrial

Product description of tungsten carbide bushing

Tungsten carbide bushing set up by virgin tungsten carbide material. It’s shows high hardness and bending strength. That has superior performance on resisting abrasion and corrosion, which is widely used in many industries

For its widely usage. Tungsten carbide bushing are often made with high accuracy, and owing to their perfect finish, precise dimension, durability and corrosion resistance. These are highly appreciated by the clients at home and aboard.

In addition, differ from the various of application environment. There are several types of Tungsten carbide bushing. Most of the specifications are all customized. Zhuzhou Tongda Carbide has backed by rich industry knowledge and production experience of various Tungsten carbide bushing. This can produce various of Tungsten carbide bushing based on specific design.

Product specification of tungsten carbide bushing

Grade | Density | T.R.S. MPa | Performance & application recommended |

YG6A | 14.95 | 1800 | Fine grain alloy, good wear resistance. Semi-finishing of chilled cast iron, non-ferrous metals alloys, semi-finishing and finishing of hardened steel, alloy steel. |

YG8 | 14.8 | 2200 | High strength in use, impact and shock resistance higher than YG6, but wear resistance and cutting speed comparatively lower |

YN8 | 14.7 | 2000 | Corrosion Resistant, It widely used in chemical and petroleum pumps |

YG10 | 14.5 | 2400 | High strength in use, impact and shock resistance higher than YG6, but wear resistance and cutting speed comparatively lower. Roughing of cast irons, non-ferrous metals and their alloys as well as non metallic materials at low cutting speed. |

YL10.2 | 14.5 | 2400 | Fine grain alloy, good wear resistance. Used for processing hard wood, veneer board, PCB, PVC and metals |

YG20 | 14.3 | 2420 | Conventional wear resistance, high bending strength,used for steel alloy etc. |

Product Application of tungsten carbide bushing

Tungsten carbide bushing applications is wide, which is a device to protect a class of components. It is in the actual work and the role and purpose of its application environment have a great relationship. Valve applications, bushings be installed in the valve stem cap trap, in order to reduce the valve leakage, to seal; bearing applications, the use of bush to reduce wear between the bearing and the shaft seat, avoid the gap between the shaft and the hole increases and so on.

Tungsten carbide bushing production and processing of high-strength, can withstand prolonged load, with high chemical stability, alkali, alcohol, ether, hydrocarbons, acid, oil, detergent, water (sea water), and has no smell , non-toxic, tasteless, non-rust characteristics, its widely used in petrochemical industry for Submerged Oil Pump, slurry pump, water pump, Centrifugal Pump,etc.

Product feature of tungsten carbide bushing

1. High hard resistance

2. High corrosion resistance

3. Pressured resistance

4. Wear resistance

5. High bending strength

We always keep good relationship with our clients, enhancing communication.

1.We are a real factory with very very nice wholesale price with high quality and good after sales service.

2.Rearch and development team with 5 members is rich experienced. OEM and label printing

orders are welcome.

3.The MOQ is 1pc.Sample and freight fee is borne by buyer.The sample fee will be reduced in

the next big quantity order.

4.Quick delivery time. We have carbide rods in stock. Delivery time within 3 days after your payment.If quantity is customized and large,delivery time is negociate.

If have any more question, please feel free to contact with us.

contact person:Ms Sharon Chen

Email address:sharon@chinahardalloy.com

whatsapp:+8613823202651

website:www.wmcarbide.com

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com