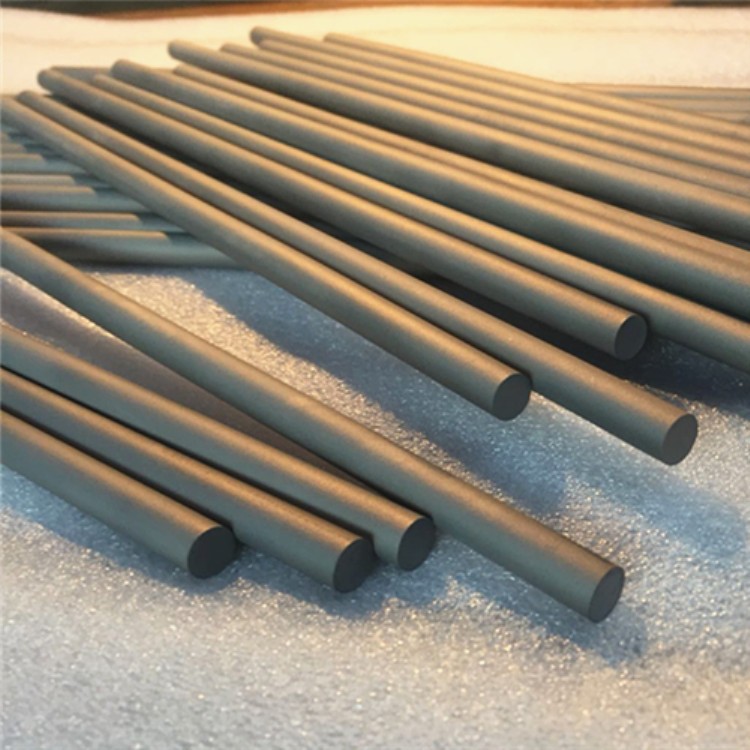

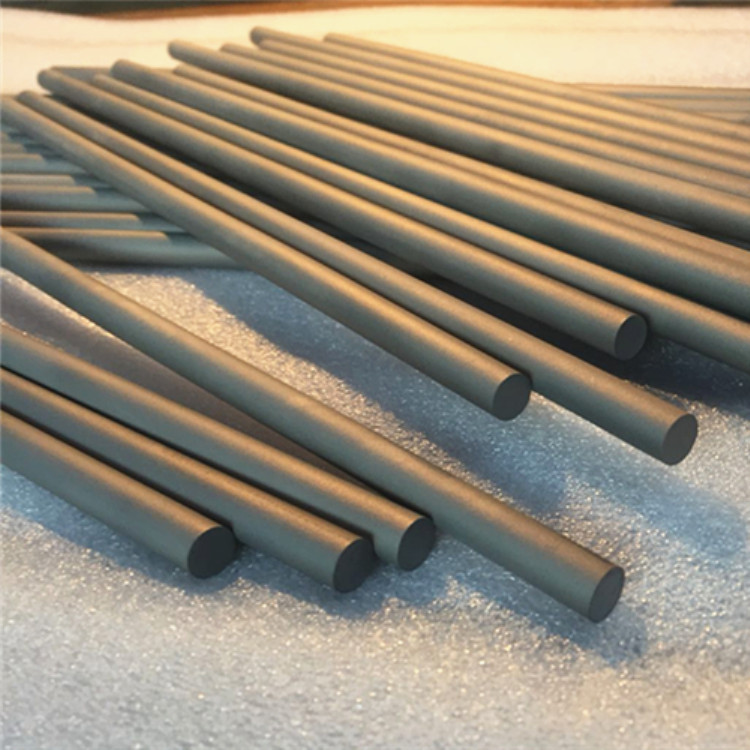

Solid Carbide Rods

330mm YG10X / YL10.2 unground solid sintered cemented carbide rod

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF00150

- Minimum Order Quantity:100 pcs

- Price:USD 45-58/kg

- Delivery Time:3-5 days

- Payment Terms:30% after confirming order the balance before shiping

- Supply Ability:100000 pcs/month

330mm YG10X / YL10.2 unground solid sintered cemented carbide rod

Solid tungsten carbide rods are used for cutting aluminum alloy, cast iron, stainless steel, refractory alloy steel, nickel based alloy, titanium alloy and nonferrous metals.widely used processed as HSS Cutting tool, carbide end mills, carbide cutting tool, NAS cutting tool, carbide end mill, aerospace cutting tool, carbide drill, high speed steel, milling cutter Core drill, taperd end mills, metric end mills, miniature end mills, pilot reamer, electronics cutter, step drill, metal cutting saw, double margin drill, gun barrel, angle milling cutter, carbide burrs, carbide tipped cutter.With several years’ development, with our good quality and competitive price, our products have been widely recognized by worldwide makers of tools. We are looking forward to establish new business with new customers.

Ungrounded Tungsten carbide rods

1. Material includes ISO K10, K20, K30 and K40F and produce all kinds of unground carbide rods and milling cutting blanks ISO h6.

2. Undertake orders of non-standard sizes at customer's requests.

| Grade | Grain size(μm) | Density(g/cm³) | Hardness(>=HRA) | TRS(>=MPA) |

| YG8 | 1.6 | 14.80 | 89.0 | 2800 |

| YG6X | 1.0 | 14.90 | 90.5 | 2300 |

| ZF05 | 0.4 | 14.80 | 93.0 | 3300 |

| LX25 | 0.8 | 14.50 | 91.3 | 3800 |

| YL10.2 | 0.8 | 14.40 | 91.5 | 4000 |

| ZF10 | 0.5 | 14.2 | 92.7 | 4400 |

| Dimension(mm) | Tolerance of diameter(mm) | Tolerance of length(mm) |

| Min BL-Φ3.0×330 | +0.20/+0.45 | -0/+5.0 |

| Max BL-Φ50.0×330 | +0.20/+0.45 | -0/+5.0 |

Our guarantee:

1. 100% raw material.

2. Sintered in HIP Furnace

3. Size standard as per your requirements

4. Professional suggestion on products

5. Feedback within 24 hours

6. ISO9001: 2015 certificate.

7. Fully adopted in advance technology and equipment.

8. Professional manufacture for tungsten carbide items with more than 13 years experience.

9. Fully adopted in advance technology and equipment.

10. Quality Control System and strict inspection.

Contact us and put our vast mechanical knowledge and manufacturing experience to work for you. And you will enjoy benefits of good quality and services from our products! ALSO, we warmly welcome you and your drawing papers.

Production Process:

Power mixing-Pressing-HIP sintering-Blank- Processing- Finished

Common size list

Grinding | Blank | ||||

D | L | D | L | ||

(mm) | Tol.(mm) | Tol.(+1mm) | (mm) | Tol.(mm) | Tol.(+3mm) |

| 0.7 | h6 | 330 | 1 | +0.2 | 330 |

2 | h6 | 330 | 2.2 | +0.2 | 330 |

3 | h6 | 330 | 2.7 | +0.2 | 330 |

3.175 | h6 | 330 | 3.2 | +0.2 | 330 |

4 | h6 | 330 | 3.7 | +0.2 | 330 |

5 | h6 | 330 | 4.2 | +0.2 | 330 |

6.35 | h6 | 330 | 4.7 | +0.2 | 330 |

7 | h6 | 330 | 5.2 | +0.2 | 330 |

8 | h6 | 330 | 5.7 | +0.2 | 330 |

9 | h6 | 330 | 6.2 | +0.2 | 330 |

10 | h6 | 330 | 6.7 | +0.2 | 330 |

12 | h6 | 330 | 7.7 | +0.3 | 330 |

12.7 | h6 | 330 | 8.2 | +0.3 | 330 |

13 | h6 | 330 | 8.7 | +0.3 | 330 |

14 | h6 | 330 | 9.2 | +0.3 | 330 |

15 | h6 | 330 | 9.7 | +0.3 | 330 |

16 | h6 | 330 | 10.2 | +0.3 | 330 |

17 | h6 | 330 | 10.7 | +0.3 | 330 |

18 | h6 | 330 | 11.2 | +0.3 | 330 |

20 | h6 | 330 | 12.2 | +0.3 | 330 |

| 25 | h6 | 330 | 14.3 | +0.3 | 330 |

| 30 | h6 | 330 | 16.2 | +0.3 | 330 |

For more size information, please kindly email or call us.For length, we can cut to any size.

Our packing

Based on Detail products, we use different Standard packing suitable overseas shipment.

For carbide rod packing as following

1. outsizde carton or plywood case

2. inner packing is plastic box or small carton with cotton or paper protection

If have any more information, please feel free to contact with me.

Contact person:Ms Sharon Chen

Mobile phone:+86-18173388506

Email address:sharon@chinahardalloy.com

Website:www.wmcarbide.com

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 6A-block,Tianyikeji industrial park, Qunfeng town, Tianyuan district, Zhuzhou, Hunan, China 412000