Carbide Wear Parts

YG6 cemented tungsten carbide brazed tips welding tips for cutting tool A325, A320 etc

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: K10,K20,K30

- Minimum Order Quantity:10 pcs

- Price:USD 45-58/kg

- Delivery Time:3-5 days

- Payment Terms:30% after confirming order the balance before shiping

- Supply Ability:100000 pcs/month

YG6 cemented tungsten carbide brazed tips welding tips for cutting tool A325, A320 etc

Specifications

1.CIP pressed,extruded ,HIP sintered

2. tungsten carbide BUTTON

3.Exellent supplier

4.100% quality guarantee

application

It is a carbide mining tool applicable to the manufacturing of heavy rock drilling machine, slice or column bore bit used for digging hard rock, various gear wheel drilling

bits; it is also applicable to the manufacturing of stone wall in building installation project, concrete drilling bit, it can also be used for crashing aluminum oxide and stone.

| Product Name | Good quality YG8c ss10 tip tungsten carbide brazed tips for stone cutting machine |

| Type | SS10 |

| Grade | YG8C |

| Material | Tungsten Carbide |

| Surface | Blank |

| Size | 10.2*4*13.5mm |

| Hardness | 88.8 |

| TRS | 2700 |

| Density | 14.68 |

| Grain Size | 1.6 |

| Packaging | Inner package:1kg/plastic box Outside package: carton |

| MOQ | 10kgs |

| Delivery | 15-25days |

Good quality YG8c ss10 tip tungsten carbide brazed tips for stone cutting machine

Features:

1. Top 100% virgin raw material

2. Excellent wear-resistance

3. High impact resistance

4. Stable chemical properties

5. Careful surface treatment and perfect appearance

6. Easier to braze, and long service time

7. Made by precision moulds, better diemsional accuracy and uniform

8. Various types and grades available

Tungsten carbide brazed inserts

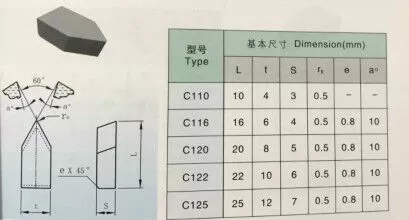

Types:

Main Types: A&B5 / A&B6 / A&B8 / A&B10 / A&B12 / A&B16 / A&B50 / etc.

C5 / C6 / C8 / C10 / C12 / C16 / C20 / C25 / C32 / C40 / C50.

D3 / D4 / D5 / D6 / D8 / D10 / D12.

E4 / E5 / E6 / E8 / E10 /E12 / E16 / E20 / E25 / E32 / etc.

F10 / F13 / F 16 / F20 / F25 / F60 / etc.

G8 / G10 / G12 / G16 / G20 / G25 / G30.

K110 / K112 / K114 / K116 / K118 / K120 / K122 / K124 / K126.

K030B/D, K032B/D, K034B/D, K036B/D, K038B/D, K040B/D, K044B, K046B, etc.

C1 type for example

Other types,dimensions and customized design are all available.

grades of tungsten carbide material for your reference:

Grade | ISO grade | Physical and mechanical properties | ||

Density(g/cm3) | Hardness(HRA) | TRS(N/mm2) | ||

YG15 | K40 | 13.9-14.1 | ≥86.5 | ≥2020 |

YG16C | 13.7-14.1 | ≥84.0 | ≥2400 | |

YGH40 | 13.5-13.9 | ≥83.0 | ≥2450 | |

YG20 | 13.4-14.8 | ≥83.5 | ≥2480 | |

YG20C | 13.4-14.8 | ≥82.5 | ≥2480 | |

YLH90 | 13.2-13.5 | ≥81.5 | ≥2580 | |

YLH100 | 13.0-13.4 | ≥81.0 | ≥2650 | |

YT15 | 11.1-11.6 | ≥91.0 | ≥1180 | |

YW1 | 12.7-13.5 | ≥91.5 | ≥1180 | |

YL10.2 | 14.3-14.5 | ≥91.0 | ≥4000 | |

Welcome and please tell us if you need the customized sizes and grades!

Company introduction

1 We are a Real Factory in Zhuzhou City.

2. High density,Good machinability ,High modulus of elasticity ,Strong corrosion resistance,Non-poisonous ,Good mechanical properties

3.100% QC inspection Before Shipment.

4. We guarantee that all of our products are used with 100% Virgin Raw Material.

5. We can produce the Special Non-standard Shaped Carbide Products as per your sample or drawing.

Zhuzhou Zhenfang Yaguang Tungsten-Molybdenum Co.,LTD is a professional manufacture in tungsten carbide field. We have engaged in this field for over ten years. We have rich experience on tungsten carbide studying and manufacture.We pursuit providing efficient solution and high quality products for clients. We specialize in tungsten carbide rod, carbide plate&strips, carbide dies, carbide roller, carbide wear parts for petrochemical industry, carbide cutting tools.Tungsten carbide rod and customized wear parts is our advantage.

We always keep good relationship with our clients, enhancing communication and Cooperation to each other, trying to create WIN--WIN cooperation.

If have any further problem, please feel free to contact with me.

Contact information

contact person:Ms Sharon Chen

Mobile number:86-18173388506

email address:sharon@chinahardalloy.com

webiste:www.wmcarbide.com

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 6A-block,Tianyikeji industrial park, Qunfeng town, Tianyuan district, Zhuzhou, Hunan, China 412000