Carbide Wear Parts

Ballistic button bit tungsten carbide DTH button bit rock drilling button bit

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF0095

- Minimum Order Quantity:500 pcs

- Price:USD 45-58/kg

- Delivery Time:7-15 days

- Payment Terms:100% TT before shiping

- Supply Ability:100000 pcs/month

Ballistic button bit tungsten carbide DTH button bit rock drilling button bit

If have any more information, please feel free to contact with me. And warmly welcoem to visit our factory.

Conter person:Ms Sharon Chen

Email:sharon@chinahardalloy.com

Mobile phone:+86-181733888506

Website:www.wmcarbide-rods.com

Our factory is professionally produce customized, non-standard, special and non-magnetic parts.

Our business is focus on:

1. Customized and special shape parts and workblank.

2. Non-standard parts and workblank.

3. Dies or workblank of stretching, drawing, cutting, flatting, hot forging, cold heading, cold extruding, forming for all related machinery industry.

4. Non-magnetic alloy dies for magnetic industry.

5. Standard parts of rod, block, bar and stick, etc.

6. Mining tools like bits, blaze, inlay cutter, sand maker's T- bar and R-bar, etc.

7. Other wear-resistance, anti-corrosion and non-magnetic product.

Application:

Tungsten Carbide ball tooth is widely used in oil drilling and snow removal of snow plough device.In addition, carbide ball tooth in the cutting tool and coal mining machinery, road maintenance and drill tool also has a good application.Mining with cemented carbide balls tooth mainly used for quarrying, mining, and mining tools in tunnel and civil construction.

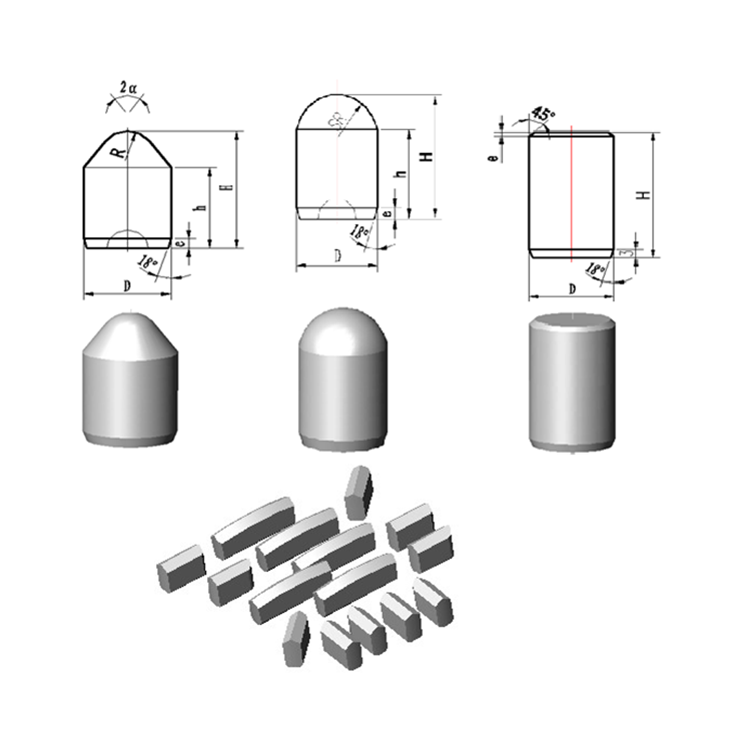

Carbide button type

2. Conical Carbide button Type

3. Ballistic Carbide Button type

4. Scoop Carbide Button Type

5. Wedged Carbide button Type

6. Flat Carbide button Type

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 7 buildings in area C, High-tech Auto parts City, Zhongda Road, Tianyuan District, Zhuzhou City, Hunan Province.