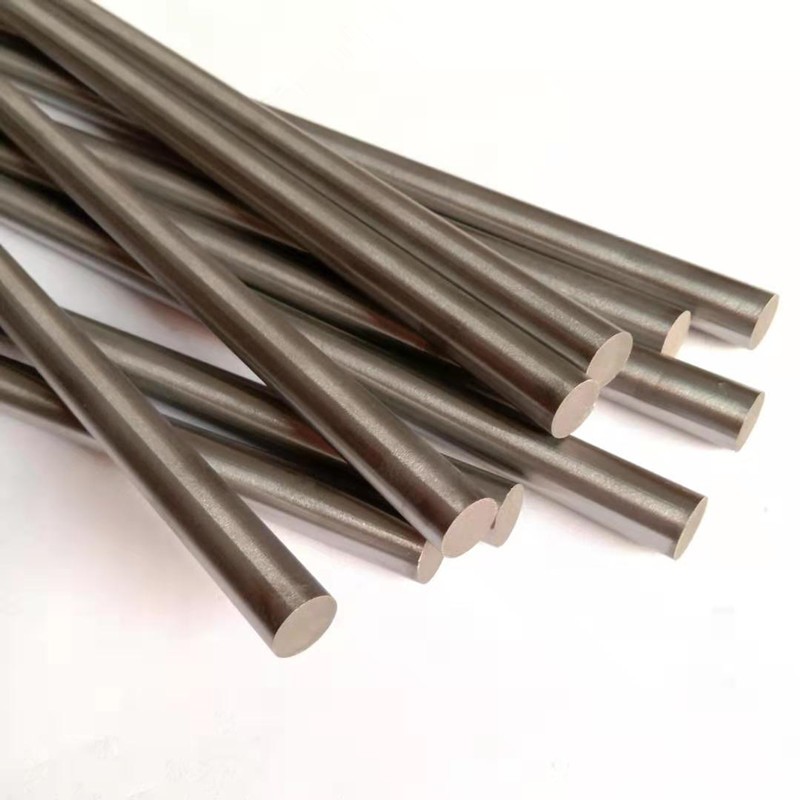

Tungsten Carbide Drill Blanks

Corrosion Resistant Tungsten Carbide Rod Blanks For Rock Drilling Bits

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF-R186

- Minimum Order Quantity:10 pcs

- Price:negotiable

- Delivery Time:3-10days

- Payment Terms:L/C, D/A, D/P, T/T, Western Union

- Supply Ability:15tons/month

Corrosion Resistant Tungsten Carbide Rod Blanks For Rock Drilling Bits

Carbide rods are one of our best-selling products.

We can produce carbide rods diameter from 0.3mm to 35mm with length

310mm, 330mm or 340mm, or others. Grade in YL10.2,YG10X, YG6, YG8 etc.

And h5 or h6 tolerance, or other requirement.

Our standard size models:

| Dimension DXL | Tolerance of diameter(mm) | Tolerance of length(mm) |

| Φ2.0×330 | +0.3/+0.5 | +0/+5.0 |

| Φ4.0×330 | ||

| Φ6.0×330 | ||

| Φ8.0×330 | ||

| Φ10.0×330 | ||

| Φ10.0×330 | +0.30/+0.70 | +0/+5.0 |

| Φ12.0×330 | ||

| Φ14.0×330 | ||

| Φ16.0×330 | ||

| Φ18.0×330 | +0.40/+1.0 | +0/+5.0 |

| Φ20.0×330 | ||

| Φ22.0×330 | ||

| Φ24.0×330 | ||

| Φ26.0×330 | ||

| Φ28.0×330 | ||

| Φ30.0×330 |

For more size information, please kindly call or email us

Carbide Rod Grade Information

Carbide Rods Grades for Drills

| Grade | ISO Grade | WC% | Co% | Grain Size μm | Density g/cm3 | Hardness (HRA) | T.R.S. N/mm2 | Application |

| YG3X | K01 | 97 | 3 | 0.6 | 14.8 | 92 | 1400 | good wear resistance, Suitable for high-speed finishing of cast iron, non-ferrous metals and their alloys, crushed steel and alloy steel |

| YG3 | K05 | 97 | 3 | 0.8 | 14.8 | 90.5 | 1450 | suitable for Semi-precision turning, thread and hole enlargement of continuous cutting of cast iron non-ferrous metals and their alloys |

| YG6A | K10 | 94 | 6 | 0.4-0.6 | 14.7 | 91.5 | 1500 | Fine grain alloy, good wear resistance, suitable for semi-finishing of chilled cast iron, non-ferrous metals and their alloys |

| YG6 | K20 | 94 | 6 | 0.8 | 14.6 | 90 | 1600 | Wear resistance is higher, but lower than YG3. Shock and vibration resistance is better than YG3X. Suitable for semi-finishing and finishing of cast iron, non-ferrous metals and alloys, non-metallic materials with medium cutting speed. |

| YG8 | K30 | 92 | 8 | 0.8 | 14.5 | 89.5 | 1700 | It has high strength, impact resistance and seismic resistance, but its wear resistance and allowable cutting speed are lower than YG6. Suitable for low speed roughing of cast iron, non-ferrous metals and alloys, non-metallic materials. |

| YG6X | K10 | 94 | 6 | 0.6-0.8 | 14.9 | 92 | 2000 | Suitable for processing Chilled cast iron, heat-resistant alloy steel, and fine process of common cast iron |

| YL10.2 | K25-K35 | 90 | 10 | 0.4-0.6 | 14.5 | 92.8-93 | 4800 | Wear resistance and strength comparatively higher,suitable for PCB micro drills,for making drills,end mill, reamer, taps, burrs etc. |

| YG15 | 85 | 15 | 0.8 | 14.1 | 87 | 2100 | suitable for drawing steel bars and steel pipes under high compression rate, And Forging, piercing and stamping tools and |

Application of tungsten carbide rod

Our tungsten carbide rod manufactured with high hardness and toughness, vibration-resistance, especially no stick when working.

It is widely used for making

- various kinds of carbide solid tools and cutting tools, such as drills, end mills, thread taps, rotating file,etc.

- A good material for general-purpose. Suitable for machining carbon steel, cast irons, stainless steel, heat-resistance steel, nickel based alloys and titanium alloys.

- Tungsten Carbide wear Parts

- Tungsten Carbide Moulding dies

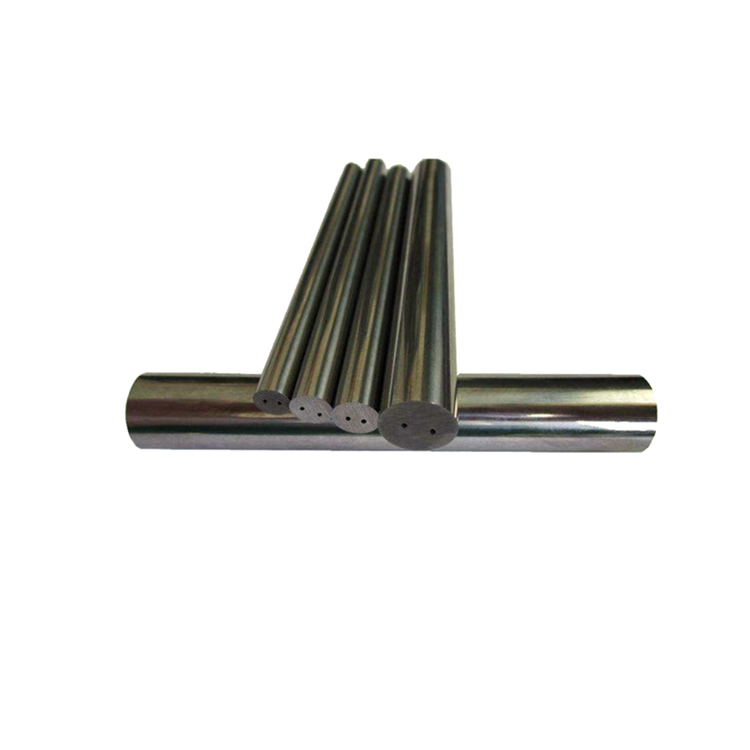

Our tungsten Carbide Rod Type

blank tungsten carbide rod, ground carbide rod, carbide rod with hole, fixed carbide rod, chamfered carbide rod

For more detail size,pls email us,thanks

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 7 buildings in area C, High-tech Auto parts City, Zhongda Road, Tianyuan District, Zhuzhou City, Hunan Province.