Custom Tungsten Carbide Parts

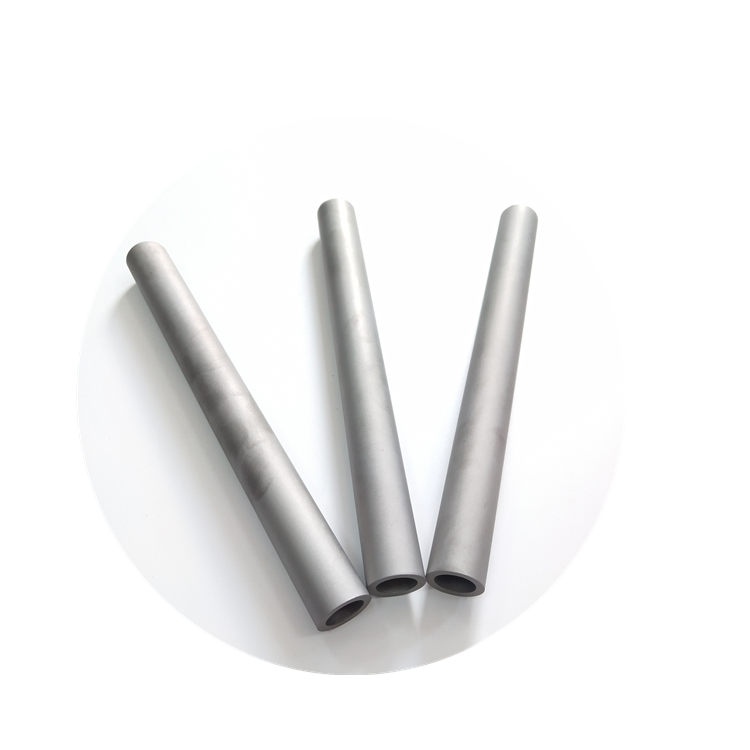

OEM&ODM high wear resistance tungsten carbide bushing cemented carbide sleeve for valve

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: YG6, YG8, YG15

- Price:Quote based on drawings

OEM&ODM high wear resistance tungsten carbide bushing cemented carbide sleeve for valve

Tungsten carbide bushing set up by virgin tungsten carbide material. It’s shows high hardness and bending strength. That has superior performance on resisting abrasion and corrosion, which is widely used in many industries

2. Various kinds of grades are availalbe based on customer's application.

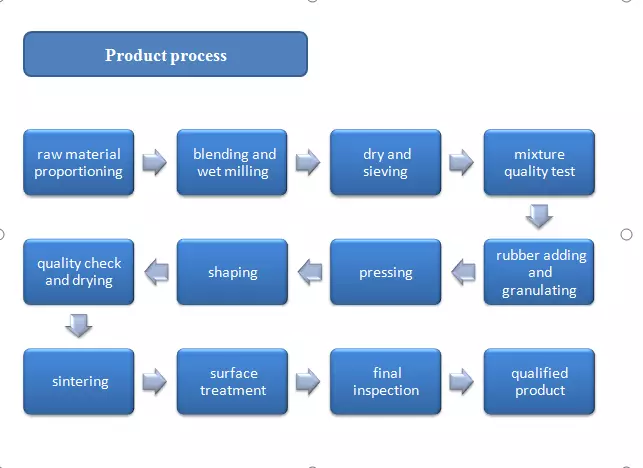

3. we have professional advanced production line and inspeciton equipments to ensure high quality

4. Precision Ground and high polishing process

5. High wear resistance,high hardness and impact toughness

6. Advanced technology , precise grinding.

Features

These carbide bushing have high temperature resistance, wear resistance and corrosion resistance It is mainly used for the sealing of oil pump valves such as sand wells, heavy oil wells, offshore oil wells and high-pressure sulfur-resistant oil wells in the petroleum industry.

Quality control:

1.All raw materials are tested in terms of density, hardness and TRS, each rod will be drop from 1.2m higher place

2.Every piece of product goes through in-process and final inspection

3.Every batch of product can be traced

Service

We supply various material grades includes standard YG8, YG6, YG6X, etc. Using good carbide is like using thin kerf saw blades.

The differences are not dramatic but they are important. Good carbide will reduce breakage and give better quality cuts overall.

There are several types of Carbide, including advanced grades. Our R&D Team can supply you with more information about these advanced grades and tungsten carbide grades when you make the inquiry.

Detail Production Information:

1. Tungsten Carbide rod

2. Tungsten Carbide Sealed Ring

3. Tugnsten Carbide Wear parts

4. Tugnsten Carbide Dies

5. Tungsten Carbide Non-standard parts

6. Tungsten Carbide Circular Blade

1.We are a real factory with very very nice wholesale price with high quality and good after sales service.

2.Rearch and development team with 5 members is rich experienced. OEM and label printing

orders are welcome.

3.The MOQ is 1pc.Sample and freight fee is borne by buyer.The sample fee will be reduced in

the next big quantity order.

4.Quick delivery time. We have carbide rods in stock. Delivery time within 3 days after your payment.If quantity is customized and large,delivery time is negociate.

If have any more information, please feel free to contact with me.

Contact person:Ms Sharon Chen

Mobile phone:+86-18173388506

Email address:sharon@chinahardalloy.com

Website:www.wmcarbide.com

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com