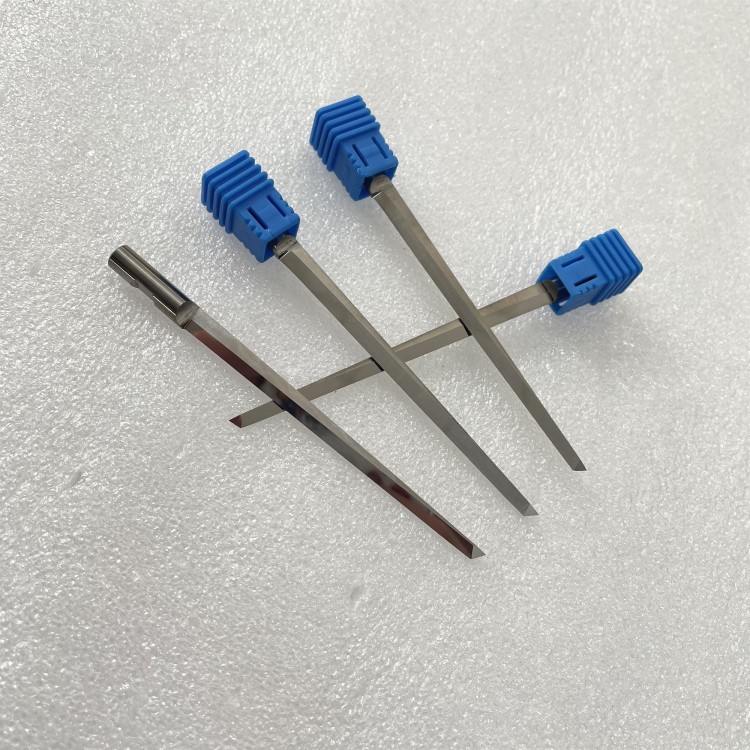

Tungsten Products

WCu 75/25 Tungsten Copper Alloy Bar / Electrode Per KG Price

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: WCu75/35

- Price:Quote based on drawings

WCu 75/35 Tungsten Copper Alloy Bar / Electrode Per KG Price

| Material | Tungsten copper alloy |

| Grade | WCu10 WCu15 WCu20 WCu25 WCu30 WCu50 |

| Shape | rod/bar |

| Copper content | 7%-50% |

| Density | 11.85g/cm3-17.2g/cm3 |

| MOQ | 1kg |

| Surface | polishing,burnishing,black surface |

| Dimension | dia1.0mm min*L1500mm max |

| Quality | ISO9001:2008 |

Chemical composition:

| Code No. | Chemical Composition % | Mechanical properties | ||||||

| CU | Impurity | W | Density (g/cm3 ) | Hardness HB | RES( cm) | Conductivity IACS/ % | TRS/ Mpa | |

| CuW50 | 50+/-2.0 | 0.5 | Balance | 11.85 | 115 | 3.2 | 54 | |

| CuW55 | 45+/-2.0 | 0.5 | Balance | 12.3 | 125 | 3.5 | 49 | |

| CuW60 | 40+/-2.0 | 0.5 | Balance | 12.75 | 140 | 3.7 | 47 | |

| CuW65 | 35+/-2.0 | 0.5 | Balance | 13.3 | 155 | 3.9 | 44 | |

| CuW70 | 30+/-2.0 | 0.5 | Balance | 13.8 | 175 | 4.1 | 42 | 790 |

| CuW75 | 25+/-2.0 | 0.5 | Balance | 14.5 | 195 | 4.5 | 38 | 885 |

| CuW80 | 20+/-2.0 | 0.5 | Balance | 15.15 | 220 | 5.0 | 34 | 980 |

| CuW85 | 15+/-2.0 | 0.5 | Balance | 15.9 | 240 | 5.7 | 30 | 1080 |

| CuW90 | 10+/-2.0 | 0.5 | Balance | 16.75 | 260 | 6.5 | 27 | 1160 |

Application

1. EDM (Electrical Discharge Machining) electrodes;

2. ECM (Electrochemical Machining) electrodes;

3. Machining other parts, toy and so on;

4. Industries as engine,electric power,electron,metallurgy,spaceflight and aviation.

Features

1. High hardness, high density, High strength, high heat resistant;

2. Excellent thermal and electrical conductivity;

3. Better arc burning loss resistance, erosion resistance;

4. Easy to be machined.

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com