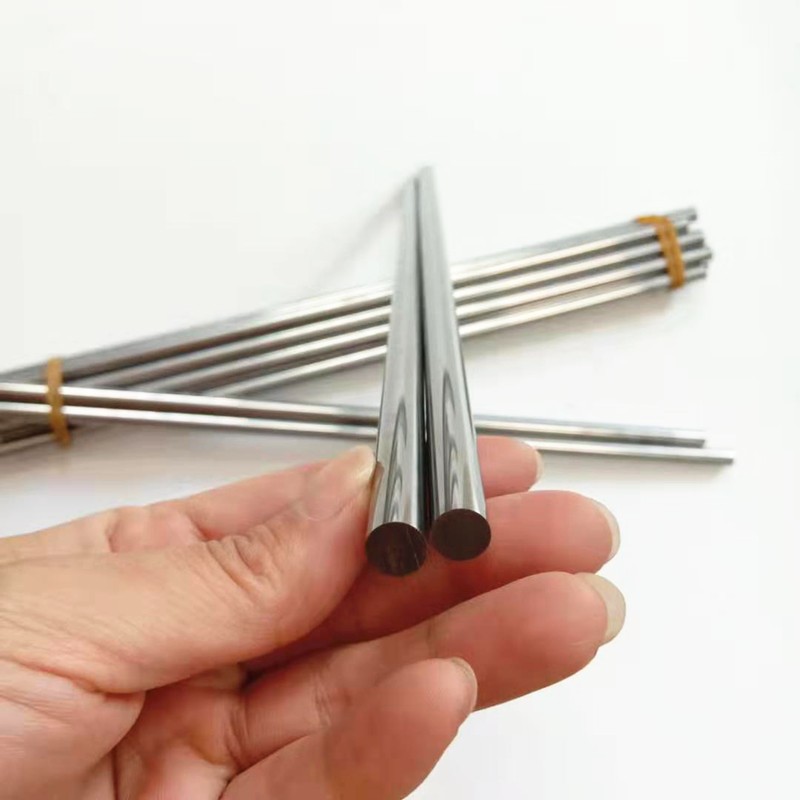

Solid Carbide Rods

High Abrasion Proof Solid Carbide Rods , Round Shape Cemented Carbide Bar

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF-R884

- Minimum Order Quantity:10 pcs

- Price:negotiable

- Delivery Time:3-10days

- Payment Terms:L/C, D/A, D/P, T/T, Western Union

- Supply Ability:15tons/month

High Abrasion Proof Solid Carbide Rods , Round Shape Cemented Carbide Bar

Production Features

1. we are using 100% WC and the raw matearils of CO.

2. High hardness HRA89-93 ,good bending strength TRS 2800-4200.N/mm2

3. Long probation,stamping.

4. Has good wear resitance.

5. Professional manufacturer for more than 10years experience.

6. ISQ 9001-2015 Quality Control System.

7. With the HIP sintered technology,the structure of tungsten carbide is more uniform,more dense,the TRS can be raised more than 20%

We make tungsten carbide rods extruded or pressed.

Diameter from 0.35mm to 50mm,

length in 330mm or 340mm.

Grade in K10, K20 K30, K35 or etc.

Application of tungsten carbide rod

Used for making various kinds of carbide solid tools and cutting tools, such as drills, end mills, thread taps, rotating file,etc. A good material for general-purpose. Suitable for machining carbon steel, cast irons, stainless steel, heat-resistance steel, nickel based alloys and titanium alloys.

Specification

| Material: | tungsten carbide |

| Dimension: | Dia12*75/100/150mm various size for choose |

| Ground Tolerance: | +-0.05mm based on requirement |

| Blank tolerancce: | +0.3~0.5mm |

| Grade: | K20 K30 K10, YL10.2, YG20 YG10X |

| Production Process: | Power mixing-Pressing-HIP sintering-Blank- Processing- Finished |

| Type: | round rod |

| Surface: | blank or grinding |

Performance | High hardness, wear /corrosion resistancce, good toughness, good straightness |

| Application: | production various types electrical machine & electronic progressive dies and punches.And ceramics, printing machine, plastic, rubber, leather industry and cutting machines. |

| Non-standard or tolerance | can be customized |

Our standard size models:

Size range(DiaXL mm) | Tolerance | ||

D(blank, mm) | D (ground, mm) | L(mm) | |

| Dia(0.3-0.9)x330 | +0/+0.3 | h6/h7 | 0/+2 |

Dia(1-5)x330 | +0.3/+0.4 | h6/h7 | 0/+2 |

Dia(6-20)x330 | +0.3/+0.6 | h6/h7 | 0/+2 |

Dia(21-40)x330 | +0.5/1.0 | h6/h7 | 0/+3 |

For any other sizes, we are able to custom-made according to clients’ requirements or drawings. | |||

Carbide Rods Grades for Cutting Tools

| Grade | ISO Grade | WC% | Co% | Grain Size μm | Hardness (HRA) | Density g/cm3 | T.R.S. N/mm2 | Application |

| YG6X | K10 | 94 | 6 | 0.6-0.8 | 14.9 | 92 | 2000 | Suitable for processing Chilled cast iron, heat-resistant alloy steel, and fine process of common cast iron |

| YL10.2 | K25-K35 | 90 | 10 | 0.6-0.8 | 14.5 | 92.5 | 3800 | Wear resistance and strength comparatively higher,suitable for PCB micro drills,for making drills,end mill,reamer,taps,burrs etc. |

| Grade | ISO Grade | WC% | Co% | Grain Size μm | Hardness (HRA) | Density g/cm3 | T.R.S. N/mm2 | Application |

| YG8 | K30 | 92 | 8 | 1.2 | 14.6 | 89 | 2320 | Suitable for the roughening of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

| YG6 | K20 | 94 | 6 | 1.2 | 14.9 | 89.5 | 2150 | Good Wear resistance, used for hard wood,processing original wood,aluminum section bar,brass rod and cast iron. |

| YG15 | 85 | 15 | 1.6 | 14.1 | 86.5 | 2400 | Medium grain, for mining tools, cold heading and punching dies | |

| YG20 | 80 | 20 | 1.6 | 13.7 | 85 | 2500 | suitable for stamping dies such as screw, watch parts | |

| YG20C | 80 | 20 | 1.8-2 | 13.6 | 82 | 2200 | suitable for colding heading dies, stamping dies such as shaft ,standard parts |

| Grade | ISO Grade | Density g/cm3 | Hardness HRA | T.R.S N/mm2 | Application |

| YT5 | P30 | 11.50-13.20 | 90.0 | 1750 | Suitable for heavy duty cutting of steel and cast steel and for a low-speed and medium-speed and a big feed-rate roughing operation under unfavorable machining conditions |

| YT14 | P20 | 11.20-11.80 | 91.0 | 1550 | Suitable for semi-finishing and finishing machining of steel and cast steel, using a medium feed-rate |

| YT15 | P10 | 11.10-11.60 | 91.5 | 1500 | Suitable for semi-finishing and finishing machining of steel and cast steel and a medium feed-rate and a rather high cutting speed is to be recommended |

| YC40 | P40 | 13.00-13.40 | 89.5 | 1860 | Suitable for heavy duty cutting of steel and cast steel with a possible big feed-rate and for face milling as well. |

| YW1 | M10 | 12.85-13.40 | 92.0 | 1380 | Suitable for semi-finishing and finishing of stainless and ordinary alloyed steel |

| YW2 | M20 | 12.65-13.35 | 91.0 | 1680 | Suitable for semi-finishing and finishing of stainless and low alloyed steel, mainly used for machining of trains' wheel hubs |

| YW3 | M10 | 12.85-13.10 | 92.0 | 1420 | It is suitable for semi-finishing and finishing of stainless and ordinary alloyed steel |

We guarantee:

* We are real factory in Zhuzhou

* Manufactured with100% tungsten carbide raw material

* Comply with ISO 9001:2015 Certification

* Rich experience of over 10 years

* Advanced technology , automatic pressing , HIP sintering

* Full ability to accept OEM & ODM orders

* Strict inspection for quality of raw material and finished products

Our tungsten Carbide Rod Type

For more detail size,pls email us,thanks

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 7 buildings in area C, High-tech Auto parts City, Zhongda Road, Tianyuan District, Zhuzhou City, Hunan Province.