Molybdenum Products

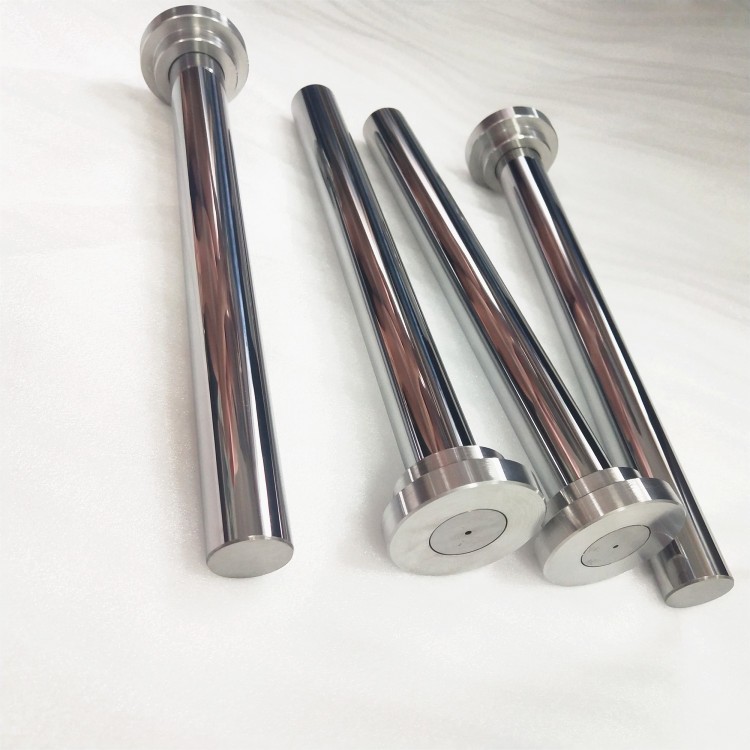

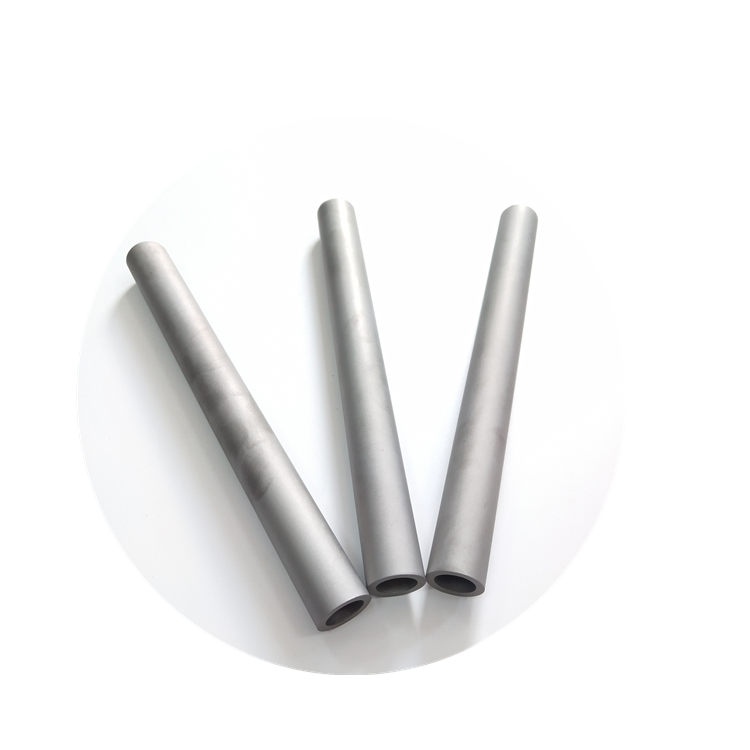

99.95% high pure polished round molybdenum rod bar price per kg

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: Mo1

- Price:Quote based on drawings

99.95% high pure polished round molybdenum rod bar price per kg

Molybdenum has a density of 10.2 g/cm3, a melting point of 2610°C, and a boiling point of 5560°C.

Molybdenum is a silver-white metal, hard and tough, high melting point, high thermal conductivity,molybdenum has the advantages of high strength, high melting point, corrosion resistance, wear resistance, etc.,

Therefore, the molybdenum part is widely used in various fields.such as used in steel, petroleum, chemical, electrical and electronic technology, medicine and agriculture.

Application:

Ion implantation parts.

Electric light source parts, electric vacuum components.

Heating elements and refractory parts in high temperature furnaces.

Used in glass and glass fiber industry, it can serve a long life in melted glass liquid at 1300°C.

Used as electrodes in the field of rare earth metal industry.

Feature:

High resistance to radiation;

High ultimate tensile strength

High temperature resistance;

Deep processing property significantly increased;

Weldability and oxidation resistance greatly enhanced;

Yield increase and cost reduction.

Composition:

Grade | The impurity content is no more than % | |||||||

Fe | Ni | Al | Si | Mg | C | N | O | |

Mo-1 | 0.01 | 0.005 | 0.02 | 0.01 | 0.002 | 0.01 | 0.002 | 0.008 |

Mo-2 | 0.01 | 0.005 | 0.02 | 0.01 | 0.002 | 0.01 | 0.002 | |

Advantages:

1. Abundant Resources--Mo Metal Reserves top of Asia in Luoyang.

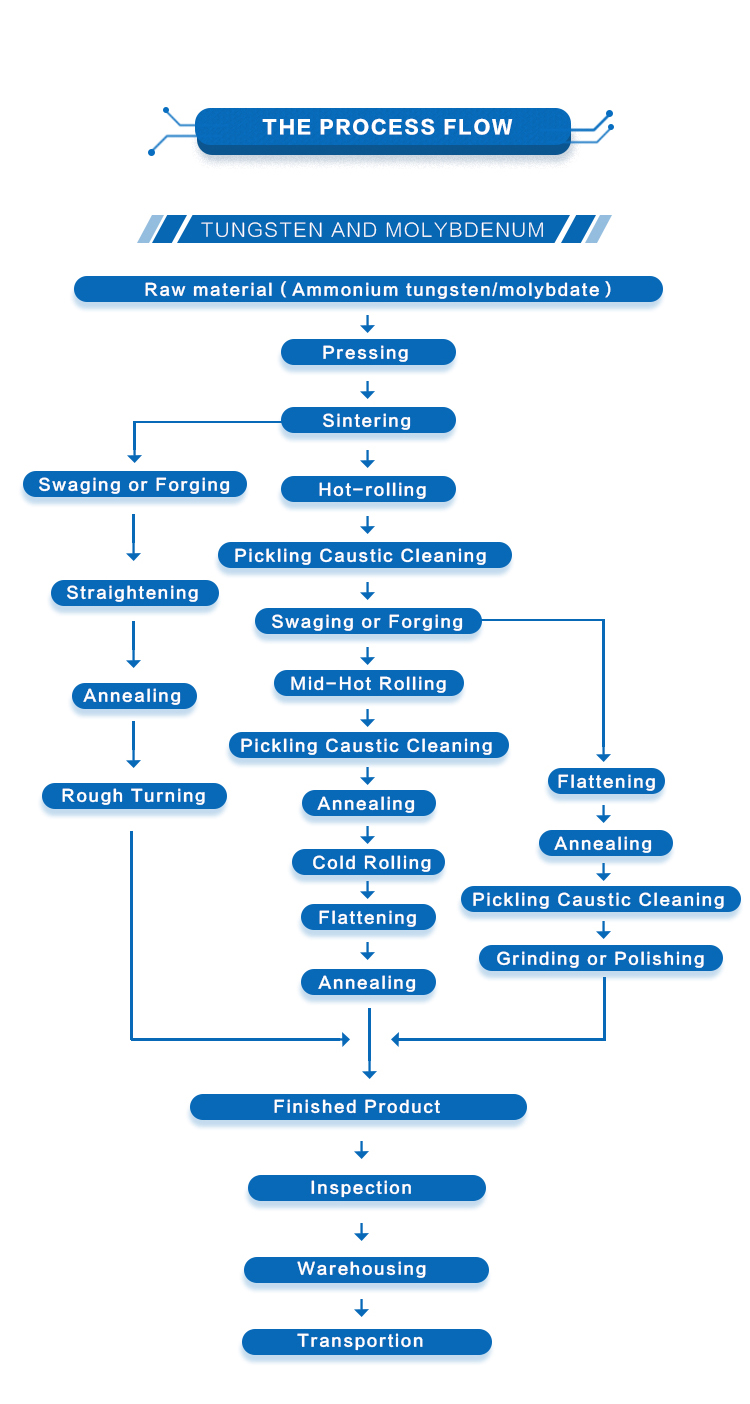

2. Have full production line- from Powder-Bars(Slab)-Plate-Rod(Wire) and alloys of tugsten and molybdenum.

3. High quality with competitive price

4. Support OEM-- we can design and produce according to the clients' requirments or drawings.

5. Fast delivery.

6. Great variety of products

Zhuzhou Zhenfang Yaguang Tungsten-Molybdenum Co.,LTD is a professional manufacture in tungsten carbide field. We have engaged in this field for over ten years. We have rich experience on tungsten carbide studying and manufacture.We pursuit providing efficient solution and high quality products for clients. We specialize in tungsten carbide rod, carbide plate&strips, carbide dies, carbide roller, carbide wear parts for petrochemical industry, carbide cutting tools.Tungsten carbide rod and customized wear parts is our advantage.

We always keep good relationship with our clients, enhancing communication.

If have any more information, please feel free to contact with me.

Contact information

contact person: Ms Sharon Chen

mobile number +86 18173388506

email address: sharon@chinahardalloy.com

Website:www.wmcarbide.com

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com