Custom Tungsten Carbide Parts

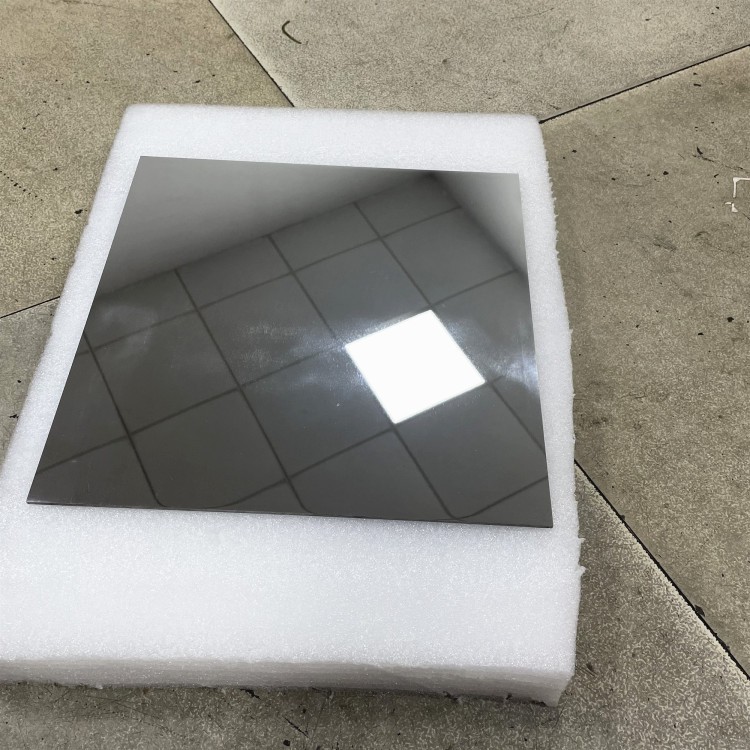

Customize high polished mirror surface and wear resistance tungsten carbide plate with 3mm thickness

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: YG6, YG8, YG15

- Minimum Order Quantity:10 pcs

- Price:USD 58-68/kg

- Delivery Time:10-15 days

- Payment Terms:T/T, western union, LC etc

- Supply Ability:100000 pcs/month

Customize high polished mirror surface and wear resistance tungsten carbide plate with 3mm thickness

Advantge of cemented tungsten carbide plate

2. High density,Good machinability ,High modulus of elasticity ,Strong corrosion resistance,Good mechanical properties

3. It can effectively absorb X rays and gamma rays (the absorption of X rays andγ rays is higher than lead 30~40%)

4. 100% QC inspection Before Shipment.

5. We guarantee that all of our products are used with 100% Virgin Raw Material.

6. Customization is avaliable

Cemented Tungsten carbide plate has many excellent characteristics such as high hardness and strength, good wear and corrosion resistance and salient stability under high temperature (even at 500 ºC it is essentially unchanged and at 1000 ºC it is still of high hardness).

Tungsten carbide plate are usually used for treating solid wood, shaving board and middle-density fiberboard,Also be used to make woodworking tools, such as forming tool, reamer, serrated knife blade and various blade,our strips meet the ISO 9001:2015 quality standard.

Mainly used in vertical shaft impact crusher (sand making machine), with high performance and high efficiency of sand making and shaping. A variety of crushing forms (stone-to-stone, stone-to-iron) to meet different crushing needs of users. Rotor with stone-stone structure-suitable for crushing sand for hard and extremely hard materials, and shaping various soft and hard materials.

It can adjust the level of stone powder content, which is suitable for the requirements of high stone powder content in grinding jade concrete, and the requirements of low stone powder content for ordinary concrete. The stone iron rotor is used-suitable for the crushing of materials below medium hardness, with high crushing efficiency, Features such as high sand production rate and easy adjustment of fineness modulus.

1. Adapt to different material crushing requirements of users. Such as: granite, basalt, limestone, quartzite, gneiss, cement

clinker, concrete aggregate, ceramic raw materials, iron ore, gold ore, copper ore, corundum, bauxite, silica, etc.

2. Compared with other materials, it has the advantages of good comprehensive performance, high reliability, strong wear

resistance, and low price!

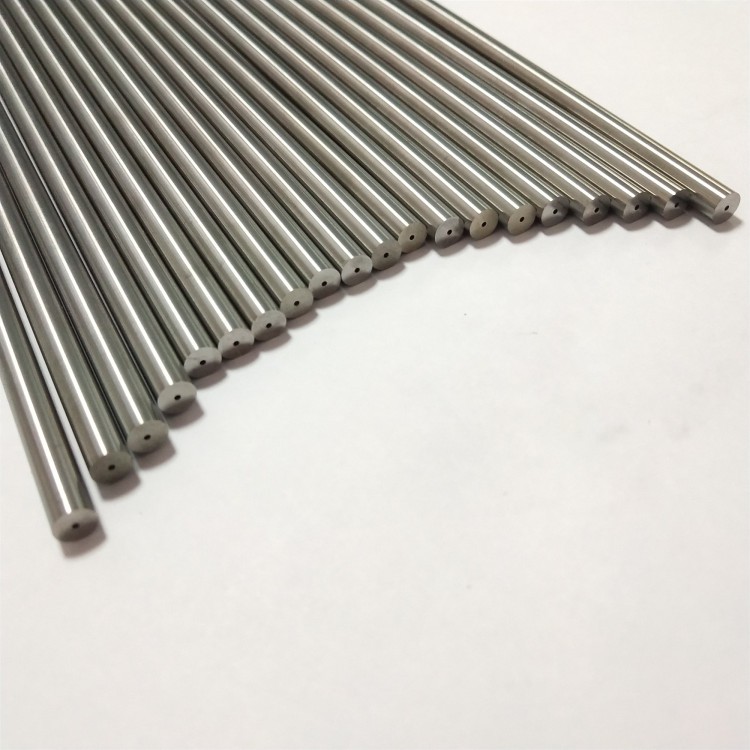

3. The length of the alloy bar can be customized according to the specifications of the throwing head, and the service life of each pair of alloys can reach 40-70 hours.

We guarantee:

* We are real factory in Zhuzhou

* Full ability to accept OEM & ODM orders

* Manufactured with100% tungsten carbide raw material

* Comply with ISO 9001:2015 Certification

* Strict inspection for quality of raw material and finished products

* Rich experience of over 10 years

* Advanced technology , automatic pressing , HIP sintering

Our packing

Based on Detail products, we use different Standard packing suitable overseas shipment.

For carbide rod packing as following

1. outsizde carton or plywood case

2. inner packing is plastic box or small carton with cotton or paper protection

1. Tungsten Carbide rod

2. Tungsten Carbide Sealed Ring

3. Tugnsten Carbide Wear parts

4. Tugnsten Carbide Dies

5. Tungsten Carbide Non-standard parts

6. Tungsten Carbide Circular Blade

If have any more information, please feel free to contact with me.

Contact person:Ms Sharon Chen

Mobile phone:+86-18173388506

Email address:sharon@chinahardalloy.com

Website:www.wmcarbide.com

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 7 buildings in area C, High-tech Auto parts City, Zhongda Road, Tianyuan District, Zhuzhou City, Hunan Province.