Custom Tungsten Carbide Parts

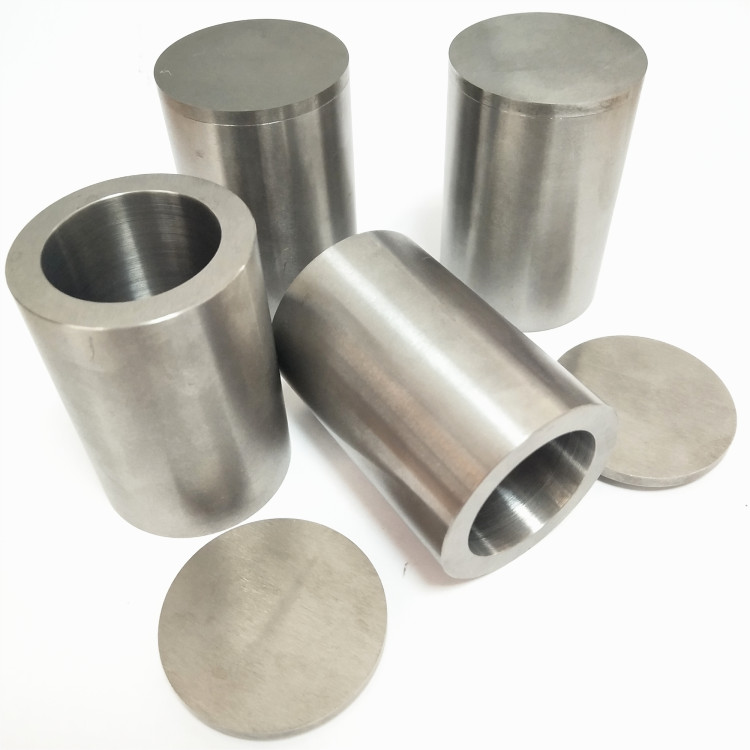

High polished tungsten carbide ball mill grinding jar for planetary ball mills carbide grinding bowl

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: YG8 YG15 YG6

- Minimum Order Quantity:10 pcs

- Price:Negotiable

- Delivery Time:10-15 days

- Payment Terms:L/C, D/A, D/P, T/T, Western Union

- Supply Ability:10000 pcs /month

High polished tungsten carbide ball mill grinding jar for planetary ball mills carbide grinding bowl

Pls feel free to contact us you have any requirments, any inquiry is welcomed!

Contact person:Ms Sharon Chen

Whatapp:+86 13823202651

WeChat;18173388506

Email address:sharon@chinahardalloy.com

Website:www.wmcarbide.com

Application:

1. Suitable for hard and abrasive samples etc.

2. Applicated for Tungsten carbide ball mill jar is used as grinding jar of planetary ball mill matched with tungsten carbide balls,

which is suitable for grinding materials in high hardness such as hard alloy powder, diamond powder, and silicon carbide powder.

Dimension: Customized base on customer drawing or samples.

Product details:

Jar Volume: 25mL~1000mL

Max Loading Capacity:2/3 capacity of the grinding jar

Density:15.5g/cm³

Main Chemical Compositions: WC (94%,92%,85%),Cobalt (6%,8%, 15%)

Surface Treatment: blank or finish

Abrasion Resistance: very good

Attachment:lid and rubber sealing gasket

Grinding Balls: mixed tungsten carbide ball(should be ordered separately)

Hardness: 92.1HRA

1. Heat resistant; very good wear resistant

2. High hardness, the vast majority of metal powder crushing

3. High hardness and impact toughness, chemical stability.

4. Long life time

5. Easy operation

It has intensive friction and controlled planetary ball mill movements allow for excellent grinding performance. This unique

combination is generated by the oval shape and the movement of the grinding jars. The grinding jar supports are mounted on two

discs respectively which turn in the same direction. The jars move on a course without changing their orientation. The shape of

jar and it movement causes strong friction between grinding balls, Material and jar inner walls as well as a rapid acceleration

which lets the balls impact with great force on the sample at the rounded ends of the jars. This significantly improves the mixing

of the particles resulting in smaller grind sizes and a narrower particle size distribution than has been possible to achieve in ball mills so far.

We are based in Hunan, China, start from 2011,sell to Southeast Asia(18.00%),North America(11.00%),South America(10.00%),Western Europe(9.20%),Eastern Asia(8.00%),Eastern Europe(7.00%),Northern Europe(5.00%),South Asia(5.00%),Southern Europe(3.00%),Mid East(2.00%),Central America(1.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

tungsten carbide rod,tungsten carbide bar,tungsten carbide wear parts,tungsten carbide blanks,tungsten carbide cutting tools tips

4. why should you buy from us not from other suppliers?

We have over 10 years experience in tugnsten carbide manufacturing and developing. Perfect quality control systerm. High products quality and speedy delivery. professional sales team. Customization is accepted.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,Express Delivery;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C,Credit Card,PayPal,Western Union,Cash;

Language Spoken:English,Chinese

Categories

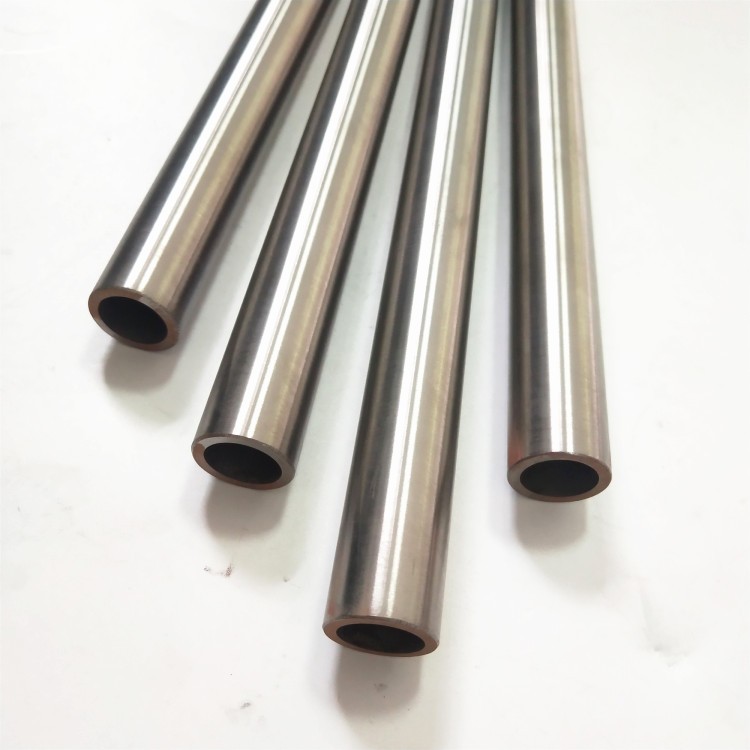

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 7 buildings in area C, High-tech Auto parts City, Zhongda Road, Tianyuan District, Zhuzhou City, Hunan Province.