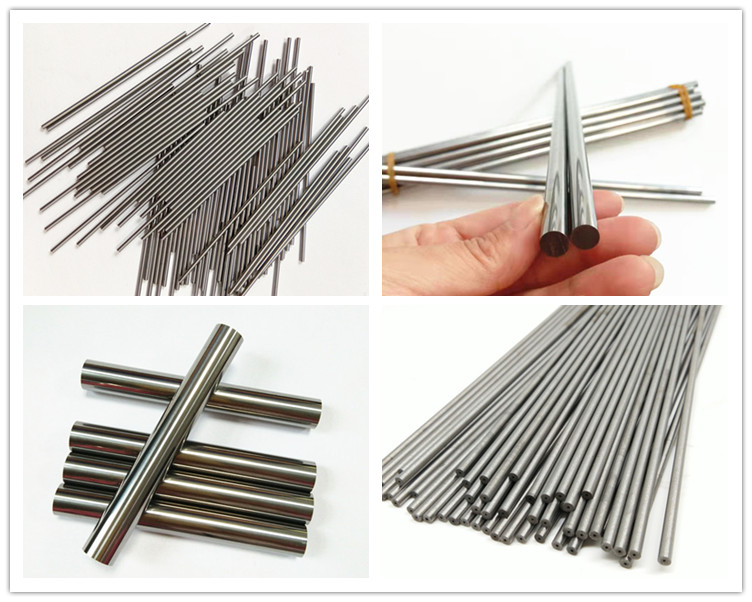

Cemented Carbide Rods

Dia12mm High Density Tungsten Carbide Rod , HRA92.8 Carbide Round Bar

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF-R459

- Minimum Order Quantity:10 pcs

- Price:negotiable

- Delivery Time:3-10days

- Payment Terms:L/C, D/A, D/P, T/T, Western Union

- Supply Ability:15tons/month

For more information, please contact me

Shirley Pan

Email:shirley@chinahardalloy.com

Mobile:+86 17773379950(wechat/whatsapp)

Dia12mm High Density Tungsten Carbide Rod , HRA92.8 Carbide Round Bar

We can supply all kinds of dimensions solid carbide rods with fine&sub micron grain size We manufactured and stocked many dimensions of ground and unground carbide rod for your.

Application Are:

1. Applied to metal Cutting:reamers,taps,end mills & PCB tools.

2. Motorcycle manufacturing industry

3. Electronin industry

4. other mold and mechanical manufacturing industry

5. Engineered Components

6. Wear Parts for Oil and petrochemical Industry

7. Tools and Tool Blanks

8. Jewellery

Some key areas where cemented carbide components are used:

Automotive components

Rotary cutters for high-speed cutting of artificial fibres

Metal forming tools for wire drawing and stamping application

Rings and bushings typically for bump and seal applications

Woodworking, e.g., for sawing and planingapplications

Pump pistons for high-performance pumps (e.g., in nuclearinstallations)

Nozzles, e.g., high-performance nozzles for Oil drilling applications

Roof and tail tools and components for high wear resistance

Balls for ball bearing and ball point pen

Various grade for your choice

| Grade | ISO Grade | WC% | Co% | Grain Size μm | Hardness (HRA) | Density g/cm3 | T.R.S. N/mm2 | Application |

| YG6X | K10 | 94 | 6 | 0.6-0.8 | 14.9 | 92 | 2000 | Suitable for processing Chilled cast iron, heat-resistant alloy steel, and fine process of common cast iron |

| YL10.2 | K25-K35 | 90 | 10 | 0.6-0.8 | 14.5 | 92.5 | 3800 | Wear resistance and strength comparatively higher,suitable for PCB micro drills,for making drills,end mill,reamer,taps,burrs etc. |

| YG8 | K30 | 92 | 8 | 0.8-1.2 | 14.6 | 89 | 2320 | Suitable for the roughening of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

| YG6 | K20 | 94 | 6 | 1.2 | 14.9 | 89.5 | 2150 | Good Wear resistance, used for hard wood,processing original wood,aluminum section bar,brass rod and cast iron. |

| YG15 | 85 | 15 | 1.6 | 14.1 | 86.5 | 2400 | Medium grain, for mining tools, cold heading and punching dies |

Production Advantages

1. we using 100% WC and the raw matearils of CO.

2. High hardness HRA89-93 ,good bending strength TRS 2800-4200.N/mm2

3. Long probation,stamping.

4. Has good wear resitance.

5. Professional manufacturer for more than 10years experience.

6. ISQ 9001-2015 Quality Control System.

7. With the HIP sintered technology,the structure of tungsten carbide is more uniform,more dense,the TRS can be raised more than 20%

8. We make tungsten carbide rods extruded or pressed.

9. Customization is acceped

Production Process:

Power mixing-Pressing-HIP sintering-Blank- Processing- Finished

Application:

production various types electrical machine & electronic progressive dies and punches.And ceramics, printing machine, plastic, rubber, leather industry and cutting machines.

Our Various Size List

Grinding | Blank | ||||

D | L | D | L | ||

(mm) | Tol.(mm) | Tol.(+1mm) | (mm) | Tol.(mm) | Tol.(+3mm) |

| 0.7 | h6 | 330 | 1.2 | +0.2 | 330 |

2 | h6 | 330 | 2.2 | +0.2 | 330 |

3 | h6 | 330 | 2.7 | +0.2 | 330 |

3.175 | h6 | 330 | 3.2 | +0.2 | 330 |

4 | h6 | 330 | 3.7 | +0.2 | 330 |

5 | h6 | 330 | 4.2 | +0.2 | 330 |

6.35 | h6 | 330 | 4.7 | +0.2 | 330 |

7 | h6 | 330 | 5.2 | +0.2 | 330 |

8 | h6 | 330 | 5.7 | +0.2 | 330 |

9 | h6 | 330 | 6.2 | +0.2 | 330 |

10 | h6 | 330 | 6.7 | +0.2 | 330 |

11 | h6 | 330 | 7.2 | +0.2 | 330 |

12 | h6 | 330 | 7.7 | +0.3 | 330 |

12.7 | h6 | 330 | 8.2 | +0.3 | 330 |

13 | h6 | 330 | 8.7 | +0.3 | 330 |

14 | h6 | 330 | 9.2 | +0.3 | 330 |

15 | h6 | 330 | 9.7 | +0.3 | 330 |

16 | h6 | 330 | 10.2 | +0.3 | 330 |

17 | h6 | 330 | 10.7 | +0.3 | 330 |

18 | h6 | 330 | 11.2 | +0.3 | 330 |

20 | h6 | 330 | 12.2 | +0.3 | 330 |

For more size information, please kindly email or call us

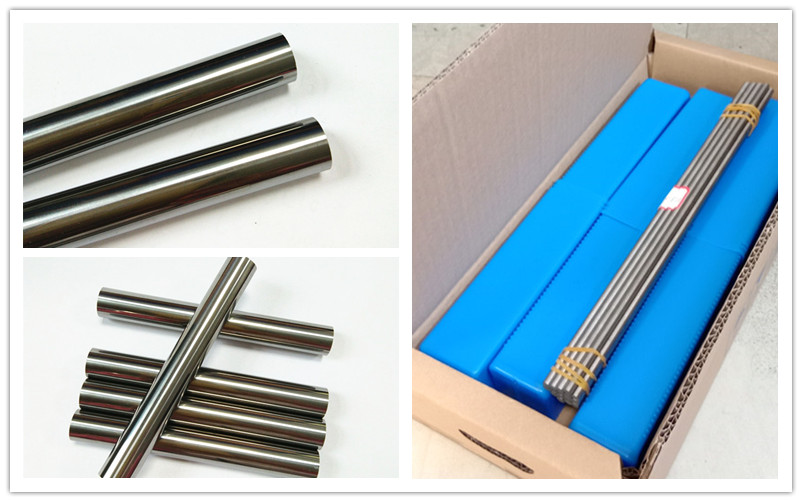

Our packing

We guarantee:

* We are real factory in Zhuzhou

* Manufactured with100% tungsten carbide raw material

* Comply with ISO 9001:2015 Certification

* Rich experience of over 10 years

* Advanced technology , automatic pressing , HIP sintering

* Full ability to accept OEM & ODM orders

* Strict inspection for quality of raw material and finished products

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 7 buildings in area C, High-tech Auto parts City, Zhongda Road, Tianyuan District, Zhuzhou City, Hunan Province.