Cemented Carbide Rods

Blank/ground thin solid 10% cobalt cemented carbide round rod for drilling hole

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: YG6, YG8, YL10.2 etc

- Minimum Order Quantity:10000 pcs

- Price:USD 55-65/kg

- Delivery Time:3-5 days

- Payment Terms:30% after confirming order the balance before shiping

- Supply Ability:10000000 pcs/month

Blank/ground thin solid 10% cobalt cemented carbide round rod for drilling hole

Product Description

The tungsten carbide rods also can be called cemented carbide rods. They can be in sintered unground condition, high precision grinding and mirror polished. They’re widely used in machining carbon steel, wood, stone, aluminum , non-ferrous metals and titanium, cast iron , stainless steel, etc. The carbide rods are widely used for making PCB drills , drills , cutters, end mills &reamers , mold punches , core pins&hole drilling tools. They also can be used for making of cemented carbide stamping head, core bar and perforation tools, used as wear resistance parts of punching mold,measuring and cutting industry ,etc.

Grade of tungsten carbide rods

Grade | Density g/cm³ | Hardness HRA | TRS (Mpa) | Recommended applications and performance |

YG6 | 14.9 | 89.5 | 2150 | With good wear resistance , suitable for hard wood, prosesisng original wood, bress rods, and cast iron |

YG8 | 14.6 | 89 | 2320 | Used for the roughening of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

YL10.2 | 14.5 | 92.5 | 3400 | Wear resistance and strength comparatively higher,suitable for processing cast iron, non-ferrous metal |

Features:

1. Made from 100% virgin raw material

2. HIP sintering

3. Stable chemical properties

4. High hardness, good compactness

5. Excellent performance and good wear / corrosion resistance

6. Blanks, high machining accuracy / precision

7. Various grades of tungsten carbide available

8. OEM customized sizes available

9. Factory’s offer

10. Strict products quality inspection

Diameter | Length |

φ0.5-12mm, Φ12.5-20mm, Φ21-30mm Or Based On Requirement

| 330mm, 330mm, 330mm Or Based On Requirement |

Welcome to contact with us^_^

if you need the customized sizes and grades!

Common size list

Grinding | Blank | ||||

D | L | D | L | ||

(mm) | Tol.(mm) | Tol.(+1mm) | (mm) | Tol.(mm) | Tol.(+3mm) |

| 0.7 | h6 | 330 | 1 | +0.2 | 330 |

2 | h6 | 330 | 2.2 | +0.2 | 330 |

3 | h6 | 330 | 2.7 | +0.2 | 330 |

3.175 | h6 | 330 | 3.2 | +0.2 | 330 |

4 | h6 | 330 | 3.7 | +0.2 | 330 |

5 | h6 | 330 | 4.2 | +0.2 | 330 |

6.35 | h6 | 330 | 4.7 | +0.2 | 330 |

7 | h6 | 330 | 5.2 | +0.2 | 330 |

8 | h6 | 330 | 5.7 | +0.2 | 330 |

9 | h6 | 330 | 6.2 | +0.2 | 330 |

10 | h6 | 330 | 6.7 | +0.2 | 330 |

12 | h6 | 330 | 7.7 | +0.3 | 330 |

12.7 | h6 | 330 | 8.2 | +0.3 | 330 |

13 | h6 | 330 | 8.7 | +0.3 | 330 |

14 | h6 | 330 | 9.2 | +0.3 | 330 |

15 | h6 | 330 | 9.7 | +0.3 | 330 |

16 | h6 | 330 | 10.2 | +0.3 | 330 |

17 | h6 | 330 | 10.7 | +0.3 | 330 |

18 | h6 | 330 | 11.2 | +0.3 | 330 |

20 | h6 | 330 | 12.2 | +0.3 | 330 |

| 25 | h6 | 330 | 14.3 | +0.3 | 330 |

| 30 | h6 | 330 | 16.2 | +0.3 | 330 |

For more size information, please kindly email or call us.For length, we can cut to any size.

Our packing

Based on Detail products, we use different Standard packing suitable overseas shipment.

For carbide rod packing as following

1. outsizde carton or plywood case

2. inner packing is plastic box or small carton with cotton or paper protection

If have any more information, please feel free to contact with me.

Contact person:Ms Sharon Chen

Mobile phone:+86-18173388506

Email address:sharon@chinahardalloy.com

Website:www.wmcarbide.com

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

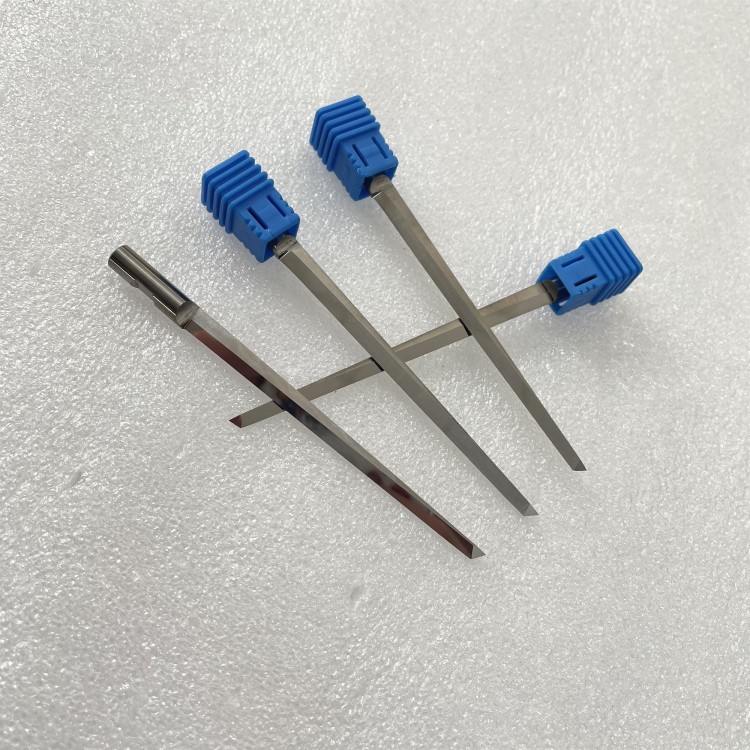

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 6A-block,Tianyikeji industrial park, Qunfeng town, Tianyuan district, Zhuzhou, Hunan, China 412000