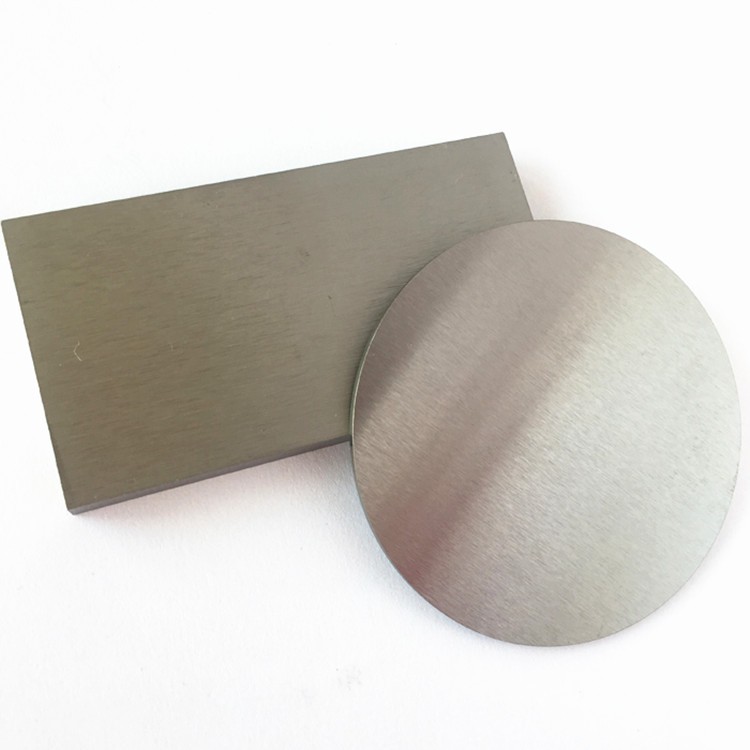

Carbide Wear Parts

Custom Tungsten Carbide Wear Parts For Mechanical Tool

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF-C78

- Price:Quote based on drawings

For more information, warmly welcome to contact us

Ms. Shirley Pan

Email:shirley@chinahardalloy.com

Mobile:+8617773379950

Custom tungsten cabide welding wearable tool part for mechanical equipment

Tungsten carbide tip is made by high quality tungsten carbide raw material, which has the character of high wear resistance and high heat resistance.

The grade generally is YG6, YG8, YGYG11,YG8C, YG15,.YG15C

these grade will greatly increase the serving life.

we produce carbide agricultural tips according to customer's drawings.

We can produce any type and size carbide plate, tile , teeth for the agriculture tool parts.

Application

we produce carbide agricultural tips according to customer's drawings.

We can produce any type and size carbide plate, tile , teeth for the agriculture tool parts.

Application

It's widely used as welding werable parts, supplied to the Agriculture, Railroad, Mining,Oil Sands, Power Generation, Construction,Aggregates, Cement, Waste Management, Transportation, and Recycling Industries with the very best carbide wear resistance in these industries.

Our advantages of Tungsten carbide tips

1. Use 100% tungsten carbide raw material

2. ISO 9001 Certification

3. with 13 years experience in R & D and manufacturing.

1. Use 100% tungsten carbide raw material

2. ISO 9001 Certification

3. with 13 years experience in R & D and manufacturing.

4. Products with high wear resistance,good toughness, long lifetime

4. Advanced technology and equipment , automatic pressing, HIP sintering, and precision grinding.

5. We accept OEM manufacturing and produce on your design.

4. Advanced technology and equipment , automatic pressing, HIP sintering, and precision grinding.

5. We accept OEM manufacturing and produce on your design.

Carbide Grade Information

Our Packing and Shipment

1. outsizde carton or plywood case

2. inner packing is plastic box or small carton with cotton or paper protection3. Shipping:UPS,TNT,EMS,Fedex,DHL, shipment by sea, or as you request.

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com