Carbide Wear Parts

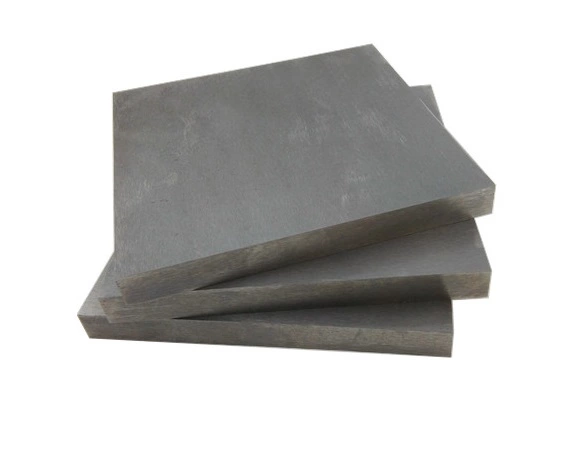

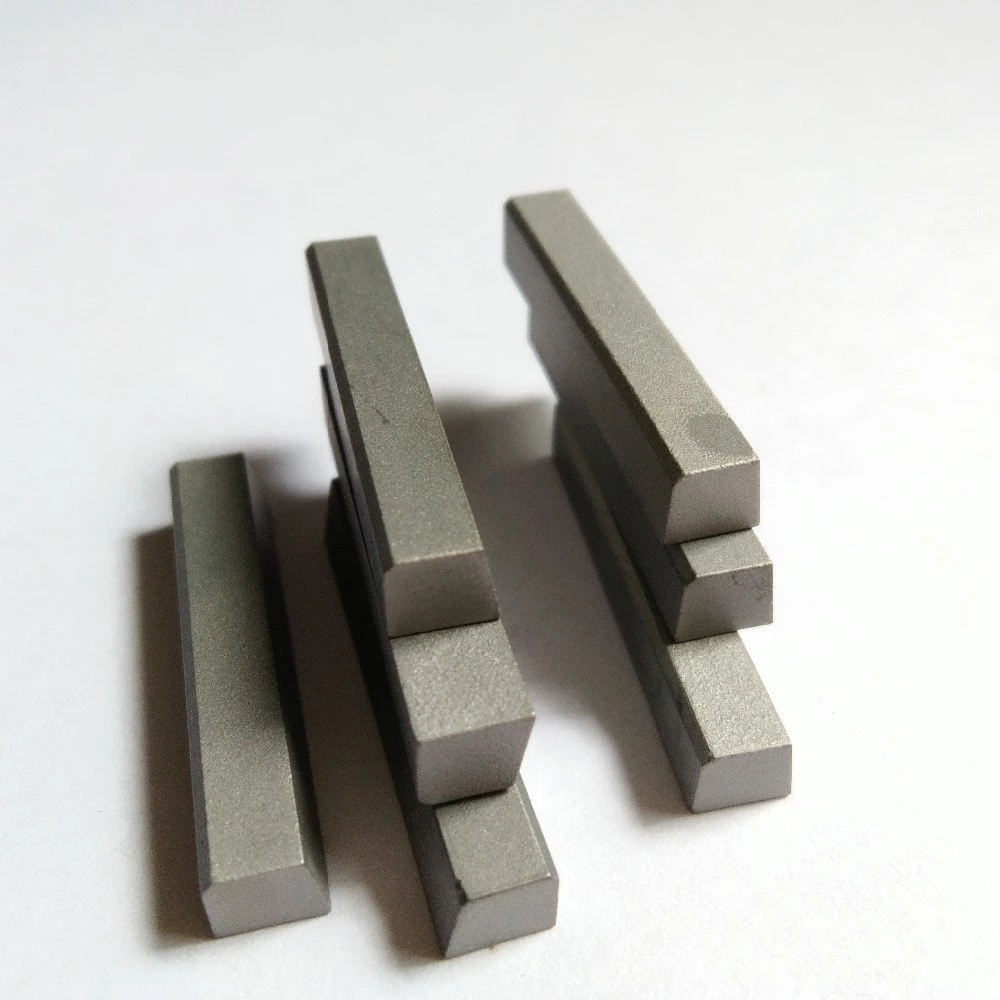

Top sale blank tungsten carbide strip, K20 carbide flat

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF00159

- Price:Quote based on drawings

Top sale blank tungsten carbide strip, K20 carbide flat

Material: 100% virgin WC+Co

Our products advantages:

1 We are a Real Factory in Zhuzhou City.

2. High density,Good machinability ,High modulus of elasticity ,Strong corrosion resistance,Non-poisonous ,Good mechanical properties

3.It can effectively absorb X rays and gamma rays

4. 100% QC inspection Before Shipment.

5. We guarantee that all of our products are used with 100% Virgin Raw Material.

6. We can produce the Special Non-standard Shaped Carbide Products as per your sample or drawing.

Other grade and size can be offered based on clients requirement

Standard Size

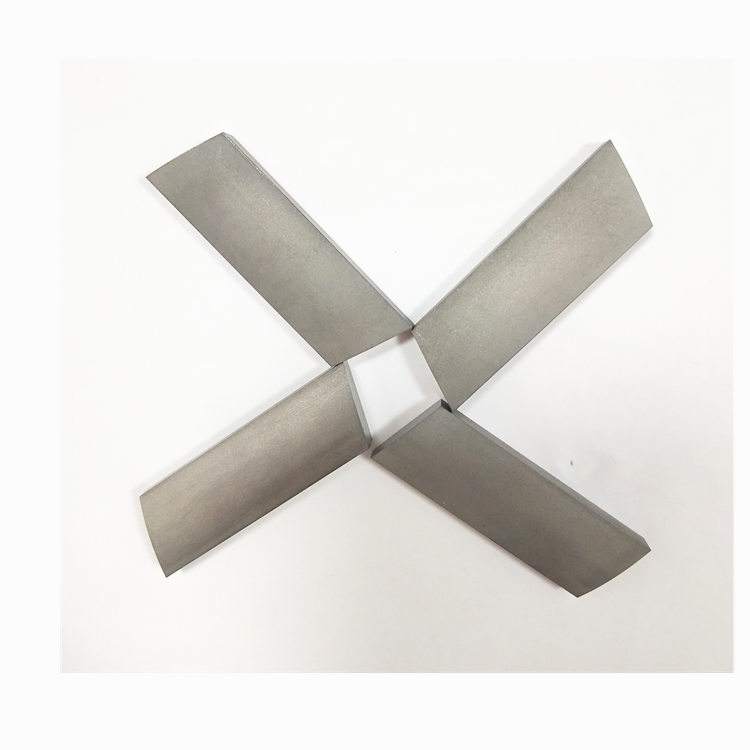

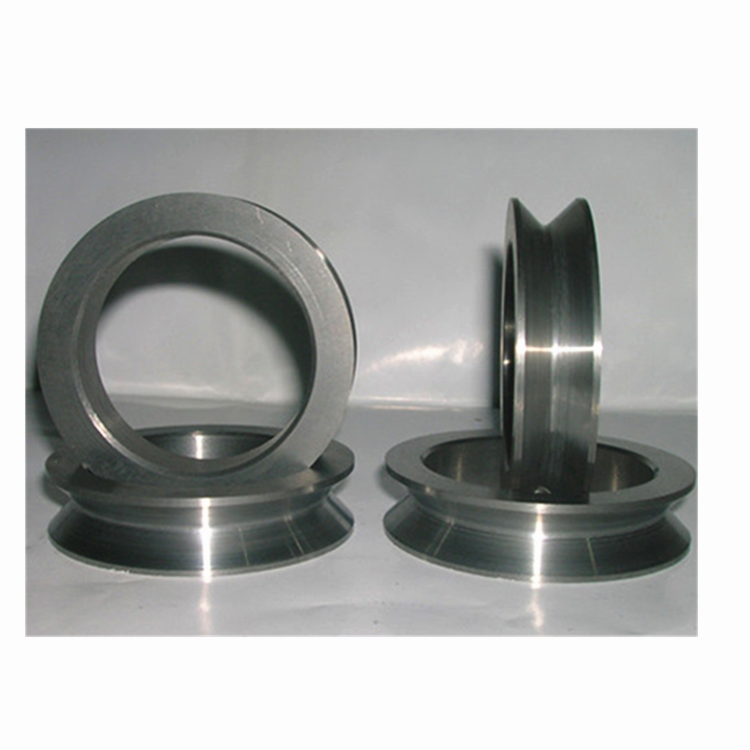

Other type carbide sheet

Zhuzhou Zhenfang Yaguang Tungsten-Molybdenum Co.,LTD is a professional manufacture in tungsten carbide field. We have engaged in this field for over ten years. We have rich experience on tungsten carbide studying and manufacture.We pursuit providing efficient solution and high quality products for clients. We specialize in tungsten carbide rod, carbide plate&strips, carbide dies, carbide roller, carbide wear parts for petrochemical industry, carbide cutting tools.Tungsten carbide rod and customized wear parts is our advantage.

We always keep good relationship with our clients, enhancing communication and Cooperation to each other, trying to create WIN-WIN cooperation.

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. after sending, we will track the products for you once every two days, until you get the products. When you got the goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer the solve way for you.

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral plyeoodcase and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages

before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR

Q4. How about your delivery time?

A: Generally, it will take 10 to 20days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

If have any more information, please feel free to contact with me.

Contact person:Ms Sharon Chen

Mobile phone:+8618173388506

Email address:sharon@chinahardalloy.com

Website:www.wmcarbide.com

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com