Carbide Wear Parts

Cemented Tungsten Carbide Cold Heading Dies With Per Kg Price

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF-TD026

- Price:Quote based on drawings

For More information, warmly welcome to contact me

Shirley Pan(Ms.)

Email: shirley@chinahardalloy.com

Mobile: +8617773379950

Cemented Tungsten Carbide Cold Heading Dies With Per Kg Price

Detail Information

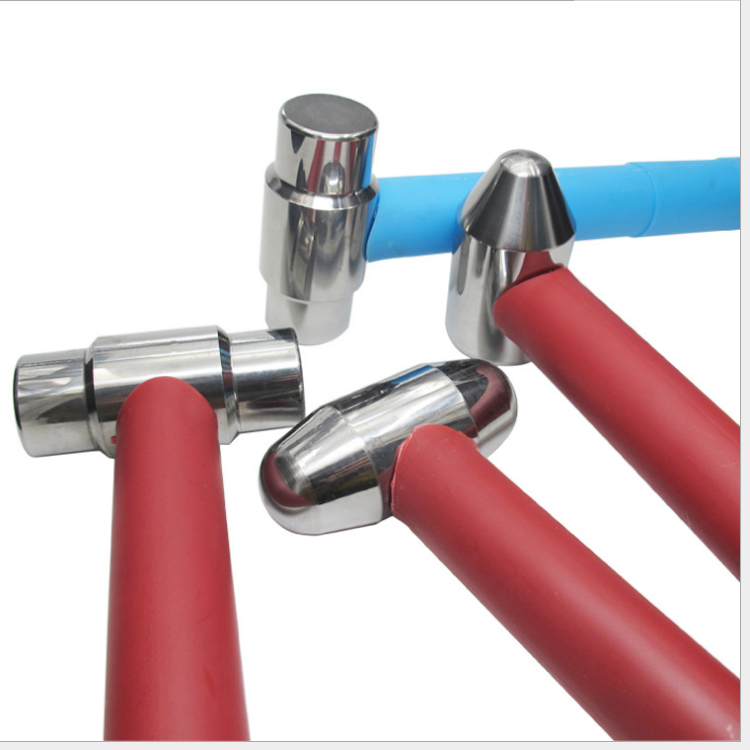

Tungsten carbide die used for cold heading and cold punching standard parts, bearing, screws and nuts. With high impact resistance, toughness and wear resistance.

Grade: YG6/ YG8/YG20C/YG15/ YG20....

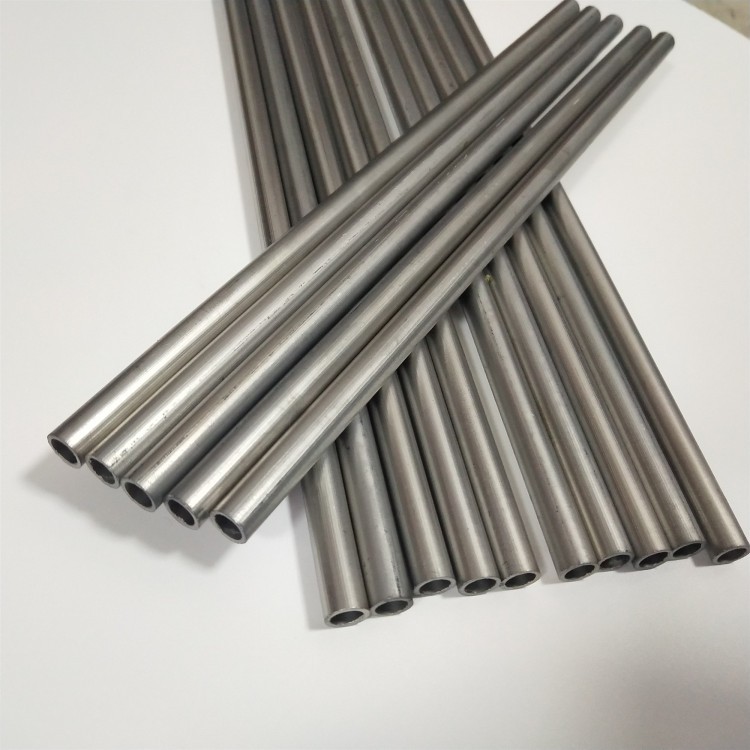

Dimension: OD16*ID2*40mm, OD30*ID5*30mm, OD60*ID28*25mm...... various size

1. Fasteners

2. Nails

3. Rivets

4. Bearings

5. Auto components

Features:

Tungsten carbide cold heading die used for cold heading and cold punching standard parts,bearing, screws and nuts etc. With high impact resistance, toughness and wear resistance. Tungsten carbide cold heading/forming dies are manufactured to bear high and repeated stress. Tungsten carbide made possible the use of cold-forming/cold heading technology for mass production of high-volume parts like screws,bolts, rivets etc. The carbide grades of Apple Carbide ensure the exceptionally long tool life while delivering

superior part accuracy.

Advantages:

1. Outstanding tool life and wear resistance.

2. Greatly improved dimensional consistency of the workpiece due to excellent transverse rupture strength and pressure resistance.

3. Uniform binder phase and content ensures substantially higher overall strength.

Recommanded Grades For Your Reference

Grade | Density g/cm3 | Hardness HRA(hv) | T.R.S (M Pa) | Performances &applications recommended |

YG6 | 14.9 | 90 | 2150 | Good Wear resistance, used for hard wood, processing original wood,aluminum section bar, brass rod and cast iron. |

YG8 | 14.6 | 89.5 | 2320 | Suitable for the roughening of cast iron and light |

YG6A | 14.9 | 92 | 1850 | fine grade alloy, with good wear resistance, used for processing blade, wear resistance parts, etc. |

YG15 | 14.1 | 86.5 | 2400 | Medium grain, for mining tools, cold heading and |

YG20 | 14 | 85 | 2500 | Medium grain, for stamping dies of Instrument leaf spring, battery shell, toothpaste, screw nut |

| YG20C | 14 | 82 | 2520 | For making cold heading and cold punching and impacting dies for standardized parts, bearings, bullet head and shell, etc. |

YL10.2 | 14.5 | 92.5 | 3400 | Wear resistance and strength comparatively |

Production process:

1. Ballmilled: To make the powder to be mixed evenly.

2. Spray drying: To make the powder into a superior homogeneous partical size, and with good flowability. So the dimension viriation on the sintered blank is much smaller.

3. Heavy duty pressing: Guaranteed that the product can be pressed and moulded at one time. And could offer a tighter tolerance control, which ensures the higher performance of the products.

4. HIP sintering: Gives the carbide blank maximum toughness. Carbide blanks are sintered at a temperature around 1400 degree which could make the carbide super hard and tough.

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com