Carbide Wear Parts

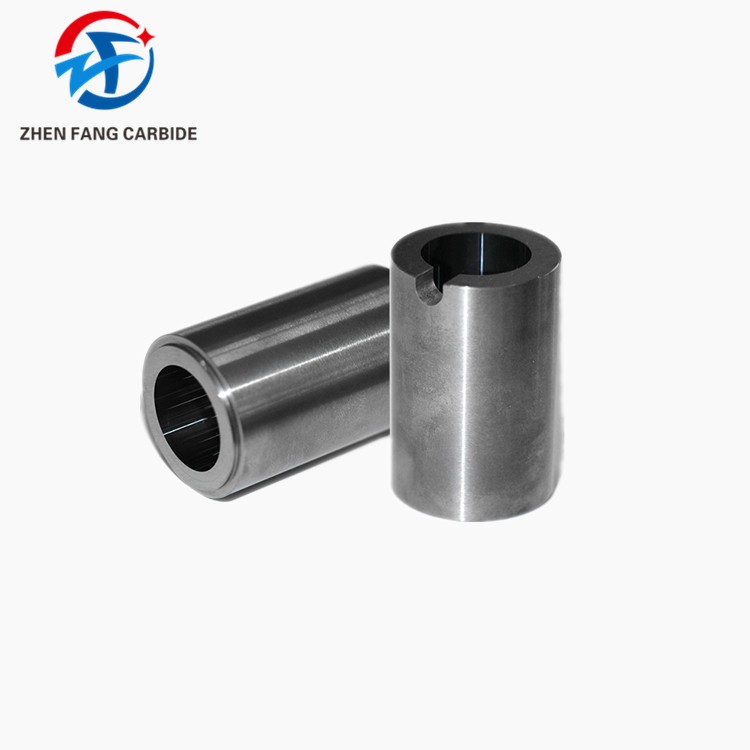

Cemented Tungsten Carbide Wear Parts Tungsten Carbide Sleeve /Bush For Oil Field Use

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF-R089

- Minimum Order Quantity:10 pcs

- Price:negotiable

- Delivery Time:3-15days

- Payment Terms:L/C, D/A, D/P, T/T, Western Union

- Supply Ability:15tons/month

For more information, warmly welcome to contact me

Shirley Pan

Email:shirley@chinahardalloy.com

Mobile:+8617773379950

Corrosion Resistance Carbide Wear Parts, Solid Carbide Sleeve For Oil Field

Products Information

1. we manufactured with 100%virgin WC+CO

2. Specification: OD110*ID 70*40mm We can manufacture Various size

3. Grade: YN6 (6% Ni, can according to clients'requirement)

4. Hardness: HRA90.5 Tougness: 2100N/mm2 Our products hardness can reach HRA92.5 Max

5. Surface: based on your requirement. we can reach mirror surface Ra0.4

Some grade for tungten carbide sleeve for reference

| Grade | Density (g/cm3) | Hardness(HRA) | Toughness (N=mm2) | Chemical Composition |

| YG6 | 14.9 | 89.5 | 2150 | Co 6% |

| YG8 | 14.6 | 89 | 2320 | Co 8% |

| YN6 | 14.8~15 | 90.5 | 2100 | Ni 6% |

| YN8 | 14.2 | 91 | 2300 | Ni 8% |

| YN9 | 14.6~14.8 | 89.5 | 2200 | Ni 9% |

| YN12 | 14.2~14.4 | 86.5 | 2250 | Ni 12% |

Introduction:

tugnsten carbide bushing made by virgin tungsten carbide material. It obtain high hardness and bending strength. It has superior performance on abrasion and corrosion resistance, which is widely used in many industries

For its widely usage. Tungsten carbide bushing are often made with high accuracy, and owing to their perfect finish, precise dimension, durability and corrosion resistance. These are highly appreciated by the clients at home and aboard.

In addition, as the various of application environment, There are several types of Tungsten carbide bushing. Most of the specifications are all customized.

Advantages:

(1). Abrasive resistant, corrosion free, good compression property, the most wear-resistant bushing, heat resistance, low maintenance ;

(2). The hardness is 10 times of gold, 5 times of tool steel, 4 times of titanium, oil resistance, separate the harmful medium;

(3). No shape change, no twist when temperature is above 1000 °C or below 500 °C, long service life, the maximum height can reach 270mm;

Tungsten carbide bushing applications is wide, which is a device to protect important components. In actual working, it have a great relationship between the rule and application environment.

Valve applications as sealing parts :bushings be installed in the valve stem cap trap, in order to reduce the valve leakage, for sealing;

bearing applications as protecting parts:the use of bush to reduce wear between the bearing and the shaft seat, avoid the gap between the shaft and the hole increases and so on.

Tungsten carbide bushing production and processing of high-strength, can withstand prolonged load, with high chemical stability, alkali, alcohol,hydrocarbons, acid, oil, detergent, water (sea water), and has no smell , non-toxic, tasteless, non-rust characteristics, its widely used in petrochemical industry for Submerged Oil Pump, slurry pump, water pump, Centrifugal Pump,etc.

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 7 buildings in area C, High-tech Auto parts City, Zhongda Road, Tianyuan District, Zhuzhou City, Hunan Province.