Carbide Wear Parts

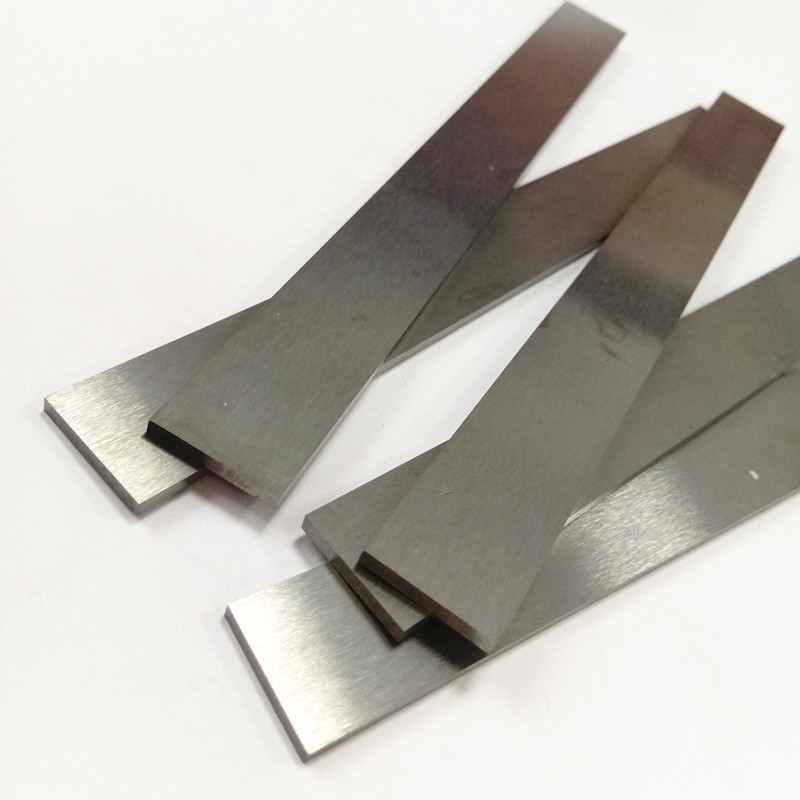

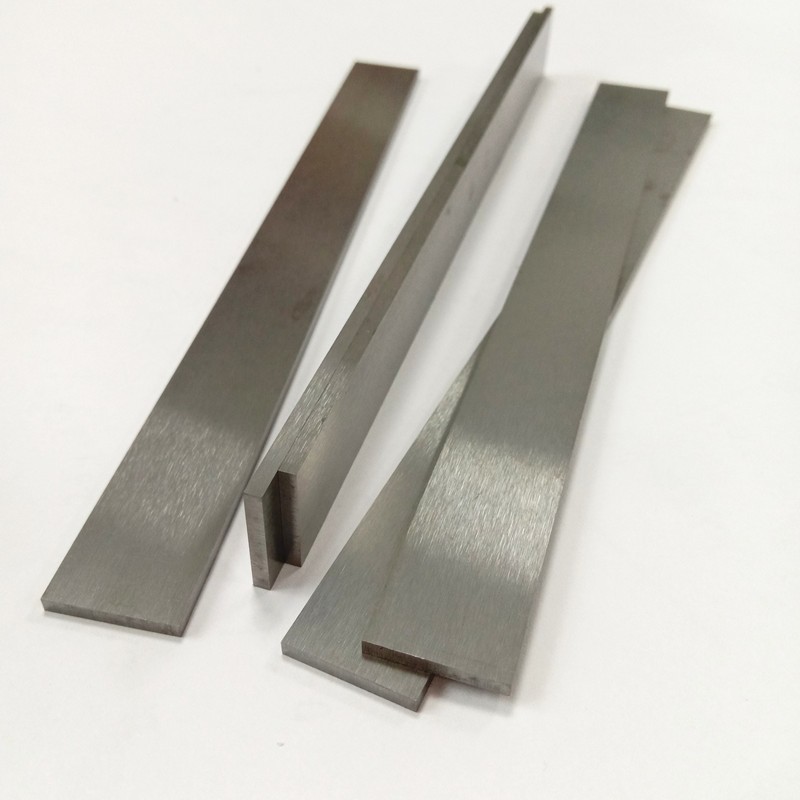

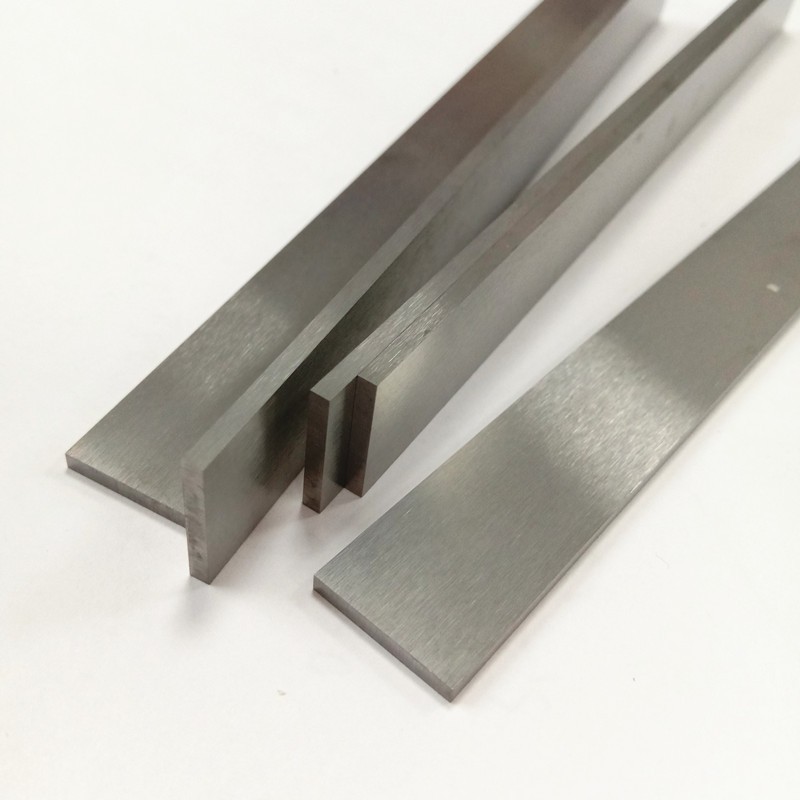

K10/K20/K30 Wearable Solid Tungsten Carbide Strips 310mm

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF-T89

- Price:Quote based on drawings

For more information, warmly welcomr to contact me

Shirley Pan

Email:shirley@chinahardalloy.com

Mobile:+8617773379950

Tungsten carbide strip, also called cemented carbide strip, are made from 100% virgin raw materials. They’re square and rectangle shapes.

The carbide strips are used in wide application field. They’re very good material to produce the parts to resist high temperature & corrosion, also widely used as wear parts, shielding parts, mold core, insert, special shape punch and so on, for cutting cast iron, nonferrous metals, plastics, chemical fiber, stainless steel and high Manganese steel, etc.

Various grades and sizes can be chosen.

| Grade | Density g/cm3 | Hardness HRA(hv) | T.R.S (M Pa) | Performances &applications recommended |

| YG6 | 14.9 | 89.5 | 2150 | Good Wear resistance, used for hard wood, processing original wood, aluminum section bar,brass rod and cast iron. |

| YG8 | 14.6 | 89 | 2320 | Suitable for the roughening of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

| YG11 | 14.4 | 87.5 | 2260 | Medium grain, for wear parts and mining tools |

| YG15 | 14.1 | 86.5 | 2400 | Medium grain, for mining tools, cold heading and punching dies |

| YG20 | 14 | 85 | 2500 | Medium grain, for stamping dies of Instrument leaf spring, battery shell, toothpaste, screw nut |

| YS2T | 14.45 | 92.5 | 2800 | Fine carbide,high wear resistance,high bending strength,high resistance to bonding, high thermal strength.Machining of refractory alloys, stainless steel and high manganese steel etc.Mainly used for disc cutter and other tools |

| YL10.2 | 14.5 | 92.5 | 3400 | Wear resistance and strength comparatively higher,suitable for processing cast iron, non-ferrous metal and non-metalloid materials. |

| YNi8 | 14.6 | 88.5 | 1710 | This grade with 8% nickel binder, it has good wear resistance& corrosion resistance perfor |

Some size list:

| Type | L(mm) | W(mm) | T(mm) | Type | L(mm) | W(mm) | T(mm) | |

| 140*W*T | 140 | 6 | 1.5~6.0 | 230*W*T | 230 | 8 | 2.0~6.0 | |

| 140*W*T | 140 | 8 | 1.5~6.0 | 230*W*T | 230 | 10 | 2.0~6.0 | |

| 140*W*T | 140 | 10 | 1.5~6.0 | 230*W*T | 230 | 12 | 2.0~6.0 | |

| 140*W*T | 140 | 12 | 1.5~6.0 | 230*W*T | 230 | 16 | 2.0~6.0 | |

| 140*W*T | 140 | 14 | 1.5~6.0 | 230*W*T | 230 | 18 | 2.0~6.0 | |

| 140*W*T | 140 | 16 | 1.5~6.0 | 230*W*T | 230 | 20 | 2.0~6.0 | |

| 140*W*T | 140 | 18 | 1.5~6.0 | 230*W*T | 230 | 22 | 2.0~6.0 | |

| 140*W*T | 140 | 20 | 2.0~6.0 | 230*W*T | 230 | 25 | 2.5~6.0 | |

| 140*W*T | 140 | 22 | 2.0~6.0 | 230*W*T | 230 | 28 | 2.5~6.0 | |

| 140*W*T | 140 | 25 | 2.0~6.0 | 230*W*T | 230 | 30 | 2.5~6.0 | |

| 165*W*T | 165 | 6 | 1.5~6.0 | 230*W*T | 230 | 32 | 2.5~6.0 | |

| 165*W*T | 165 | 8 | 1.5~6.0 | 230*W*T | 230 | 40 | 2.5~6.0 | |

| 165*W*T | 165 | 10 | 1.5~6.0 | 320*W*T | 320 | 8 | 2.0~6.0 | |

| 165*W*T | 165 | 12 | 1.5~6.0 | 320*W*T | 320 | 10 | 2.0~6.0 | |

| 165*W*T | 165 | 14 | 1.5~6.0 | 320*W*T | 320 | 12 | 2.0~6.0 | |

| 165*W*T | 165 | 16 | 1.5~6.0 | 320*W*T | 320 | 14 | 2.0~6.0 | |

| 165*W*T | 165 | 18 | 1.5~6.0 | 320*W*T | 320 | 16 | 2.0~6.0 | |

| 165*W*T | 165 | 20 | 2.0~6.0 | 320*W*T | 320 | 18 | 2.0~6.0 | |

| 165*W*T | 165 | 22 | 2.0~6.0 | 320*W*T | 320 | 20 | 2.0~6.0 | |

| 165*W*T | 165 | 24 | 2.0~6.0 | 320*W*T | 320 | 22 | 2.0~6.0 | |

| 165*W*T | 165 | 25 | 2.0~6.0 | 320*W*T | 320 | 24 | 2.0~6.0 | |

| 165*W*T | 165 | 26 | 2.0~6.0 | 320*W*T | 320 | 25 | 2.5~6.0 | |

| 165*W*T | 165 | 28 | 2.0~6.0 | 320*W*T | 320 | 28 | 2.5~6.0 | |

| 165*W*T | 165 | 30 | 2.5~6.0 | 320*W*T | 320 | 30 | 2.5~6.0 | |

| 165*W*T | 165 | 32 | 2.5~6.0 | 320*W*T | 320 | 32 | 2.5~6.0 | |

| 165*W*T | 165 | 35 | 2.5~6.0 | 320*W*T | 320 | 35 | 2.5~6.0 | |

| 165*W*T | 165 | 40 | 2.5~6.0 | 320*W*T | 320 | 40 | 2.5~6.0 |

Various size in stock. We also can customize size for your. All the products must be inspected strictly with the ultrasonic and only those haven't any harm such as pore can be shipped out. High density, high wear & impact resistance, which lead them a long lifetime.

2. Extrusion method and HIP sintering;

3. Carbide wear strips Made of 100% pure raw materials;

4. With advanced equipment and process production;

5. All tungsten carbide wear strips pass the process and final inspection;

6. The ability to stabilize and continuously produce;

7. Our carbide wear strips have high quality and good price;

8. Fast stocking capacity and timely delivery.

We supply our clients with semi-finished and finished-ground tungsten carbide strip.

We’re specialized in producing different sizes of tungsten carbide strip.

Our material covers:WC-Co alloy, WC-Ni alloy,WC-Ni/Co alloy,WC-Tic-Ni/Cr alloy etc., different grade is available.

Both standard and nonstandard parts according to the customers’drawings or samples are all available

| Packing | Outside Carton or plywood case with inner plastic box. |

| Shipping | UPS,TNT,EMS,Fedex,DHL,or by sea,as you request. |

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com