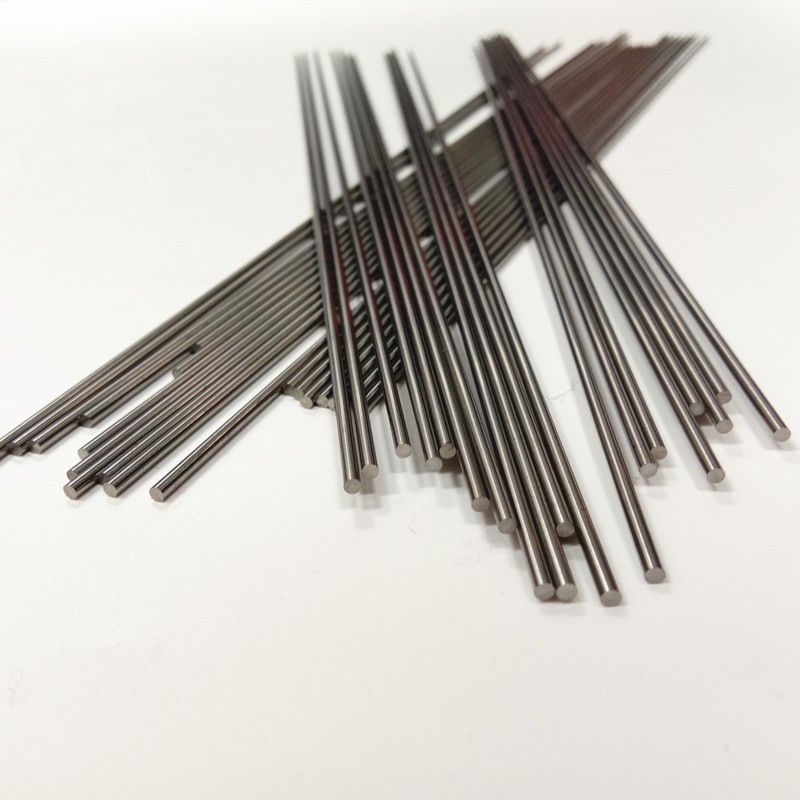

Tungsten Carbide Round Bar

Wearable Tungsten Carbide Round Bar / Rod Blanks No Stick For Cutting Tools

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF-R025

- Minimum Order Quantity:10 pcs

- Price:negotiable

- Delivery Time:3-10days

- Payment Terms:L/C, D/A, D/P, T/T, Western Union

- Supply Ability:15tons/month

For more information, warmly welcome to contact me

Shirley Pan

Email:shirley@chinahardalloy.com

Mobile:+8617773379950

Wearable Tungsten Carbide Round Bar / Rod Blanks No Stick For Cutting Tools

We manufactured and stocked a large range of dimensions unground and ground carbide rods for you, which guarantee our fast delivery.

We have a large range of grade for your choice.

We also can develop grade based on your application with fine&sub micron grain size .

We make tungsten carbide rods extruded or pressed.

Specification

| Material: | tungsten carbide WC+Co/Ni |

| Dimension: | Dia10*330/100/150mm Dia2.0*330mm various size for choose |

| Ground Tolerance: | h6 based on requirement |

| Blank tolerancce: | +0.3~1.5mm |

| Grade: | K20 K30 K10, YL10.2, YG20 YG10X |

| Production Process: | Power mixing-Pressing-HIP sintering-Blank- Processing- Finished |

| Type: | polished round rod |

| Surface: | blank or grinding |

| Performance | High hardness, wear /corrosion resistancce, good toughness, good straightness |

| Non-standard or tolerance | can be customized |

Our standard size models:

| Grinding | Blank | ||||

| D | L | D | L | ||

| (mm) | Tol.(mm) | Tol.(+1mm) | (mm) | Tol.(mm) | Tol.(+3mm) |

| 2 | h6 | 330 | 2.2 | +0.2 | 330 |

| 3 | h6 | 330 | 2.7 | +0.2 | 330 |

| 3.175 | h6 | 330 | 3.2 | +0.2 | 330 |

| 4 | h6 | 330 | 3.7 | +0.2 | 330 |

| 5 | h6 | 330 | 4.2 | +0.2 | 330 |

| 6.35 | h6 | 330 | 4.7 | +0.2 | 330 |

| 7 | h6 | 330 | 5.2 | +0.2 | 330 |

| 8 | h6 | 330 | 5.7 | +0.2 | 330 |

| 9 | h6 | 330 | 6.2 | +0.2 | 330 |

| 10 | h6 | 330 | 6.7 | +0.2 | 330 |

| 11 | h6 | 330 | 7.2 | +0.2 | 330 |

| 12.7 | h6 | 330 | 8.2 | +0.3 | 330 |

| 13 | h6 | 330 | 8.7 | +0.3 | 330 |

| 14 | h6 | 330 | 9.2 | +0.3 | 330 |

| 15 | h6 | 330 | 9.7 | +0.3 | 330 |

| 16 | h6 | 330 | 10.2 | +0.3 | 330 |

| 17 | h6 | 330 | 10.7 | +0.3 | 330 |

| 18 | h6 | 330 | 11.2 | +0.3 | 330 |

| 19 | h6 | 330 | 11.7 | +0.3 | 330 |

| 20 | h6 | 330 | 12.2 | +0.3 | 330 |

| 22 | h6 | 330 | 14.2 | +0.3 | 330 |

We can customize dimension for you.For more size information, please kindly email or call us

Carbide Rod Grade Information

Carbide Rods Grades for Cutting Tools

| Grade | ISO Grade | WC% | Co% | Grain Size μm | Hardness (HRA) | Density g/cm3 | T.R.S. N/mm2 | Application |

| YG6X | K10 | 94 | 6 | 0.6-0.8 | 14.9 | 92 | 2000 | Suitable for processing Chilled cast iron, heat-resistant alloy steel, and fine process of common cast iron |

| YL10.2 | K25-K35 | 90 | 10 | 0.4-0.6 | 14.5 | 92.8-93 | 4800 | Wear resistance and strength comparatively higher,suitable for PCB micro drills,for making drills,end mill,reamer,taps,burrs etc. |

| YG10X | K35 | 90 | 10 | 0.6-0.8 | 14.5 | 90 | 2200 | Fine diameter micro drill, vertical milling cutter, rotary file |

| Grade | ISO Grade | Density g/cm3 | Hardness HRA | T.R.S N/mm2 | Application |

| YT5 | P30 | 11.50-13.20 | 90.0 | 1750 | Suitable for heavy duty cutting of steel and cast steel and for a low-speed and medium-speed and a big feed-rate roughing operation under unfavorable machining conditions |

| YT14 | P20 | 11.20-11.80 | 91.0 | 1550 | Suitable for semi-finishing and finishing machining of steel and cast steel, using a medium feed-rate |

| YT15 | P10 | 11.10-11.60 | 91.5 | 1500 | Suitable for semi-finishing and finishing machining of steel and cast steel and a medium feed-rate and a rather high cutting speed is to be recommended |

| YC40 | P40 | 13.00-13.40 | 89.5 | 1860 | Suitable for heavy duty cutting of steel and cast steel with a possible big feed-rate and for face milling as well. |

| YW1 | M10 | 12.85-13.40 | 92.0 | 1380 | Suitable for semi-finishing and finishing of stainless and ordinary alloyed steel |

| YW2 | M20 | 12.65-13.35 | 91.0 | 1680 | Suitable for semi-finishing and finishing of stainless and low alloyed steel, mainly used for machining of trains' wheel hubs |

| YW3 | M10 | 12.85-13.10 | 92.0 | 1420 | It is suitable for semi-finishing and finishing of stainless and ordinary alloyed steel |

Application of tungsten carbide rod

Our tungsten carbide rod manufactured with high hardness and toughness, vibration-resistance, especially no stick when working.

It is widely used for making

- various kinds of carbide solid tools and cutting tools, such as drills, end mills, thread taps, rotating file,etc.

- A good material for general-purpose. Suitable for machining carbon steel, cast irons, stainless steel, heat-resistance steel, nickel based alloys and titanium alloys.

- Tungsten Carbide wear Parts

- Tungsten Carbide Mouldingdies

Production Features

- All carbide rods are made from the best tungsten carbide powders. The carbide rods are with submicron and average grain size ,the powder is even and stick together firmly,the purity of tungsten carbide powders is quite high.

- All carbide rods are made by the extrusion machine which insure that the inside structure of carbide rods is excellent and apprerance of carbide rods if better ,the flatness is improved a lot .

- All carbide rods are through HIP sintering which insure that the inside structure of carbide rods is free pore and can stick together firmly .Also the TRS is improved around 30% after HIP sintering.

- Large stock of regular sizes of carbide rods ,which can enable us to make the delivery within 24 hours.

- Replacement .we will replace the carbide rods for you if there is any defects.

Our tungsten Carbide Rod Type

blank tungsten carbide rod, ground carbide rod, carbide rod with hole, fixed carbide rod, chamfered carbide rod

For more detail size,pls email us,thanks

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

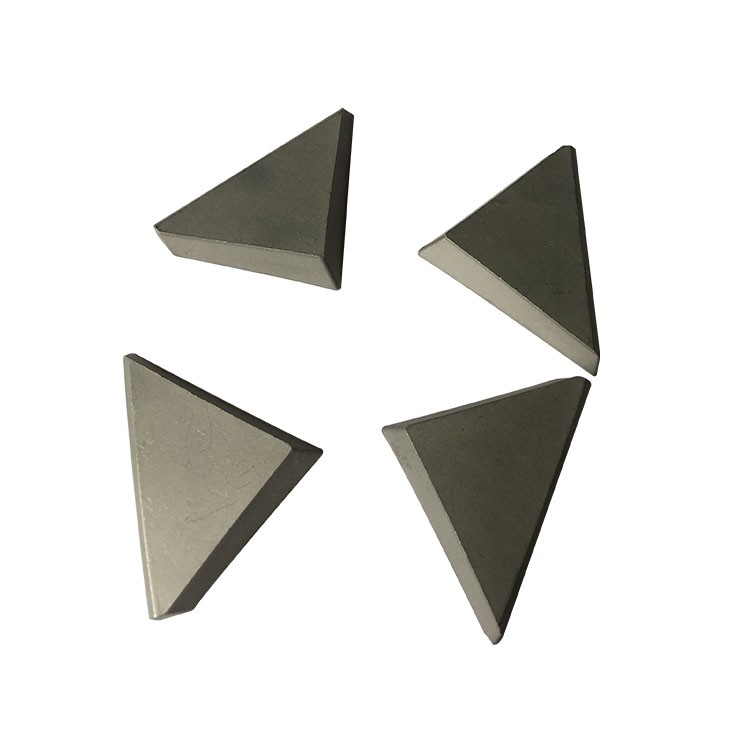

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

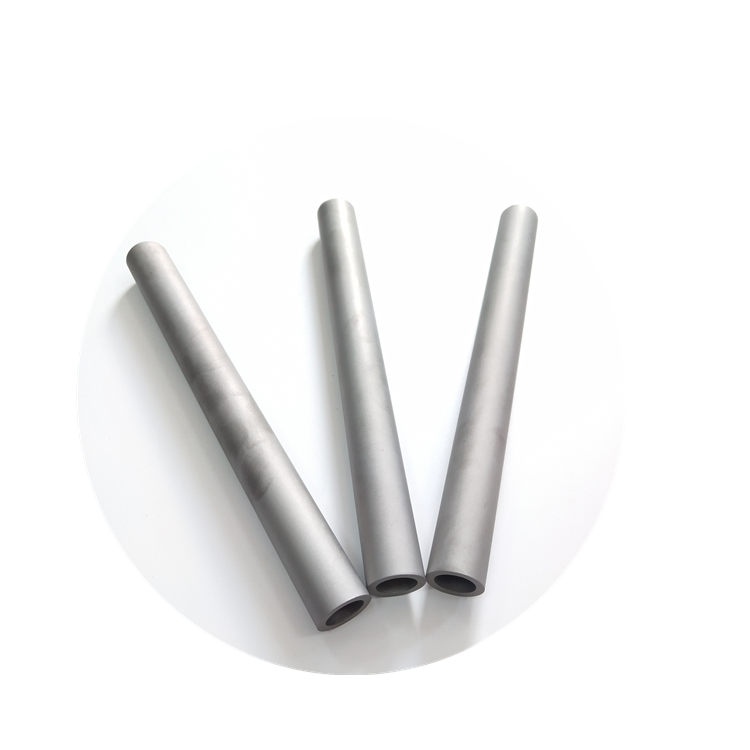

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 7 buildings in area C, High-tech Auto parts City, Zhongda Road, Tianyuan District, Zhuzhou City, Hunan Province.