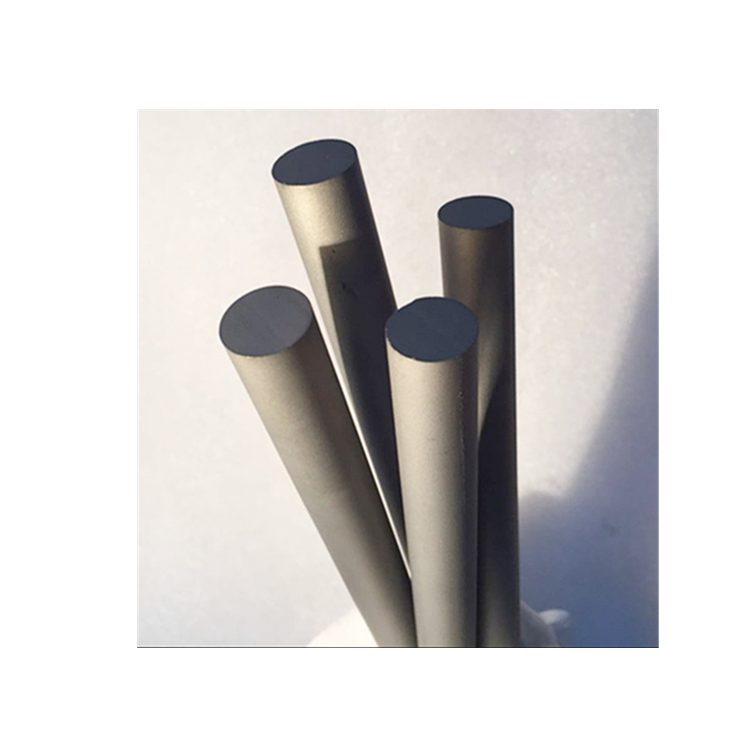

Tungsten carbide rod

150mm Length K10 Tungsten Carbide Rod High Hardness End Mill / Drill Making Use

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF-R479

- Minimum Order Quantity:10 pcs

- Price:negotiable

- Delivery Time:3-10days

- Payment Terms:L/C, D/A, D/P, T/T, Western Union

- Supply Ability:15tons/month

For more information, warmly welcome to contact me

Shirley Pam(Ms.)

Email:shirley@chinahardalloy.com

Mobile: +8617773379950(wechat/whatsapp)

150mm Length K10 Tungsten Carbide Rod High Hardness End Mill / Drill Making Use

Products Specification:

| Dimension: | Dia16*300mm, Dia26*277mm various size |

| Material: | 100% virgin tungsten carbide magnetic and non-magnetic |

| Grade: | YG6/YG8/YG6X/YS2T/YL10.2 |

| Hardness: | HRA86-92.5 |

| Surface: | ground |

| Precision: | +-0.01 based on your requirement |

| Features: | durable, high performance, no stick for cutting tools |

| Application: | Metal Tool Parts |

Introduction and Application of tungsten carbide rod

Tungsten Carbide is often referred to as a Hard Metal due to it’s very high hardness in relation to other metals. Typically a Tungsten Carbide can have a hardness value of 1600 HV, whereas mild steel would be in the region of 160 HV a factor of 10 lower.

Tungsten Carbides is m ainly used for making drills, endmills, reamers, etc. It have a wide range of application in many industry sectors such as metal machining, wear parts for mining and oil industries, metal forming tools, cutting tips for saw blades and have now expanded to include consumer items such as wedding rings and watch cases, plus the ball that is in many ball point pens.

Application Industries:

Paper, packaging, printing, Non-ferrous metal processing, Mechanical, Chemical, Petroleum, Metallurgy, Electronic, Defense industries

We can offer a lot of type tungsten carbide rods:

| 1. un-gound, finish-ground rod |

| 2. Carbide rods with one central hole |

| 3. Fixed length Carbide Rod |

| 4. Random Length carbide rod |

| 5. Carbide rods with chamfered end. |

Common Unground Dimension and Tolerance

| Dimension | Tolerance of diameter(mm) | Tolerance of length(mm) |

| ZF-Φ4.0×330 | +0.3/+0.5 | +0/+5.0 |

| ZF-Φ6.0×330 | ||

| ZF-Φ8.0×330 | ||

| ZF-Φ10.0×330 | ||

| ZF-Φ10.0×330 | +0.30/+0.70 | +0/+5.0 |

| ZF-Φ12.0×330 | ||

| ZF-Φ14.0×330 | ||

| ZF-Φ16.0×330 | ||

| ZF-Φ18.0×330 | +0.40/+1.0 | +0/+5.0 |

| ZF-Φ20.0×330 | ||

| ZF-Φ22.0×330 | ||

| ZF-Φ24.0×330 | ||

| ZF-Φ26.0×330 | ||

| ZF-Φ28.0×330 | ||

ZF-Φ30.0×330 | ||

| ZF-Φ32.0×330 | +0.7/+1.5 | +0/+5.0 |

| ZF-Φ34.0×330 | ||

We are able to help you customized various diameter and length carbide rod. gound or unground both available. We generally have inventory size from Dia1mm to Dia20mm with length330/300mm | ||

Some grade information for Reference

| Grade | Density g/cm3 | Hardness HRA(hv) | T.R.S (M Pa) | Grain Size(μm) |

| YL10.2 | 14.5 | 92.5 | 3800 | 0.6-0.8 |

| YG6 | 14.9 | 89.5 | 2150 | 0.8-1.2 |

| YG8 | 14.6 | 89 | 2320 | 0.8-1.2 |

| YG11 | 14.4 | 87.5 | 2260 | 0.8-1.2 |

| YG15 | 14.1 | 86.5 | 2400 | 0.8-1.2 |

| YS2T | 14.45 | 92.5 | 2800 | 0.6-0.8 |

| YNi8 | 14.6 | 88.5 | 1710 | 0.8-1.2 |

Our advantage of tungsten carbide rod

* We have over ten year experience

* ISO 9001:2015 Certification

* Use 100% tungsten carbide raw material

* Advanced technology , automatic pressing , HIP sintering

* Strict inspection for quality of raw material and finished products

* And precision grinding

* the tolerance of polish and ground can be +0.005/-0.005mm

* Full ability to accept OEM & ODM orders

* Stringent quality control and quality consistency.

How tugnsten carbide rod is made:

Tungsten Carbide Hard Metals are primarily produced using a Powder Metallurgy process, whereby the powdered forms of tungsten carbide and cobalt are mixed using ball mills, a binder material is added to hold the powders together during the next stage of the process which is compaction or pressing.

During the compaction processes, hydraulic presses or isostatic presses are used to compact the powders into a shape which approximates the design of the finished product.

Whilst in this condition, the powder compact can be easily machined using conventional metal working tools. This process is often referred to as “Green Machining”. Care has to be taken with the removal of the fine powder particles as they can pose a health hazard so effective extraction methods are required.

Following “Green Machining” the powder compact is then ready to be Sintered. Typically this is done in a vacuum furnace at temperatures between 1300 and 1600°C.

The sintering process causes the tungsten carbide and cobalt matrix to fuse together to produce a dense “Hard Metal”.

After sintering the material is so hard that it can only be machined by diamond grinding, a specialised form of micro machining that is relatively expensive as it is not possible to remove large amounts of materials by this process.

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 7 buildings in area C, High-tech Auto parts City, Zhongda Road, Tianyuan District, Zhuzhou City, Hunan Province.