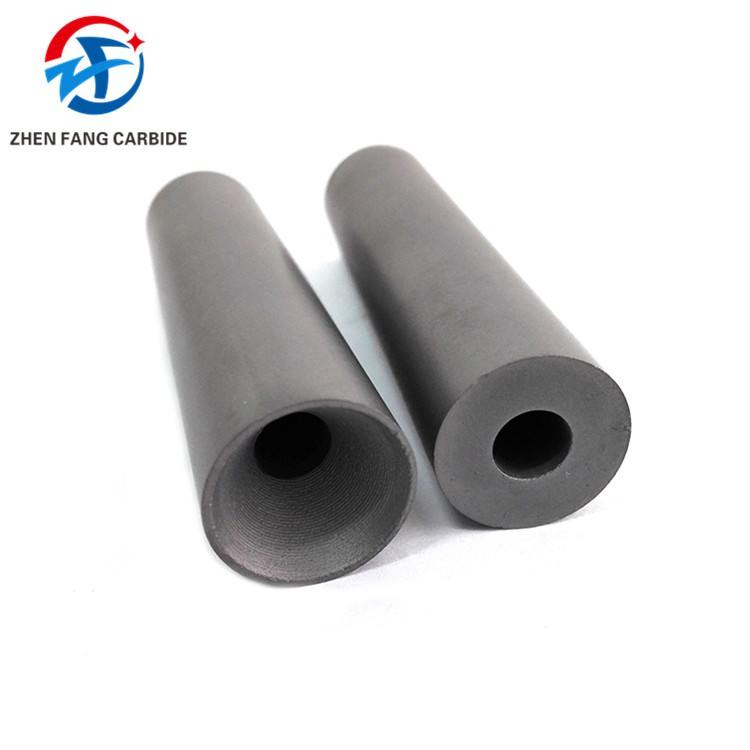

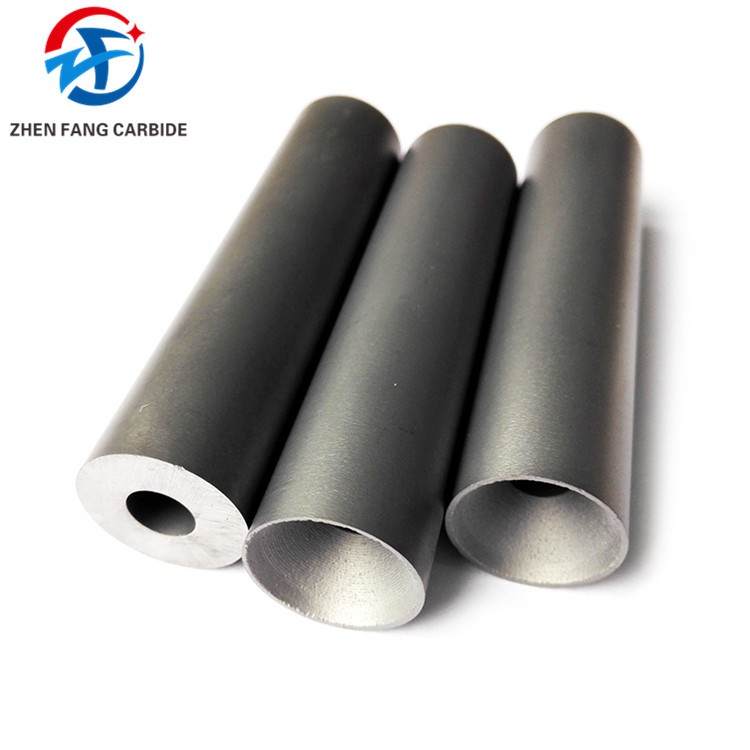

Tungsten Carbide Nozzle

HIP Sintered Tungsten Carbide Oil Spray Nozzle High Hardness With Long Lifespan

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF-N256

- Price:Quote based on drawings

For more information, warmly welcome to contact me

Shirley Pan(Ms.)

Email: shirley@chinahardalloy.com

Mobile:+8617773379950

High Hardness Tungsten Carbide Oil Nozzle For Petroleum Machinery

| Material | 100% Virgin Tungsten Carbide |

| Grade | YG8/YG6/YL10.2/YG6X...... |

| Application | sandblasting/water jet |

| Chemical composition | WC/Co |

| Property | good wear resistance and corrosion resistance |

| Grain size | ultrafine/fine/submicron/medium/coarse |

| Powder compaction | Press |

| Sintering | HIP sintering |

| Application | industrial cleaning, cooling, Oil Drilling Tools, Dust control, Painting |

Tungsten carbide nozzle is made from hot pressing with straight bore and venture bore type, which have high hardness, good wear resistance, high anti-corrosion ability. Usually they offers a long life with high performance. They are widely uased in abrasive water jet, dry/wet blasting,suction blast,scrubber,descaling,slurry jet,centrifuge and so on.

Grades of carbide sandblasting nozzle

| Grade | Density g/cm3 | Hardness HRA(hv) | T.R.S (M Pa) | Performances &applications recommended |

| YG6 | 14.9 | 89.5 | 2150 | Good Wear resistance, used for hard wood,processing original wood, aluminum section bar,brass rod and cast iron. |

| YG8 | 14.6 | 89 | 2320 | Suitable for the roughening of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

| YG11 | 14.4 | 87.5 | 2260 | Medium grain, for wear parts and mining tools |

| YG15 | 14.1 | 86.5 | 2400 | Medium grain, for mining tools, cold heading and punching dies |

| YS2T | 14.45 | 92.5 | 2800 | Fine carbide,high wear resistance,high bending strength,high resistance to bonding, high thermal strength.Machining of refractory alloys, stainless steel and high manganese steel etc.Mainly used for disc cutter and other tools |

| YL10.2 | 14.5 | 92.5 | 3400 | Wear resistance and strength comparatively higher,suitable for processing cast iron, non-ferrous metal and non-metalloid materials. |

| YN8 | 14.6 | 88.5 | 1710 | This grade with 8% nickel binder, it has good wear resistance& corrosion resistance perfor |

| YN6 | 14.9 | 89 | 1700 | This grade with 6% nickel binder, it has good wear resistance& corrosion resistance perfor |

Product Application

We can provide you all kinds of high performance nozzles, such as spray nozzles, oil nozzles, blasting nozzles and so on. With high speed to wash,well wear resistance, excellent corrosion resistance.

Tungsten carbide nozzles often be used in agricultural irrigation and urban greening.

Used in geological prospecting, machinery or tool manufacturing and serves as drill bit in wind drill and electric drills for coal dig.

Fit for precision lathe are used in nonstop cutting of die-cast iron.

Used For painting

Advantages of Tungsten Carbide Nozzle

Cost effective

Good performance property of abrasive resistance

corrosion resistance

stable property performance and long service life.

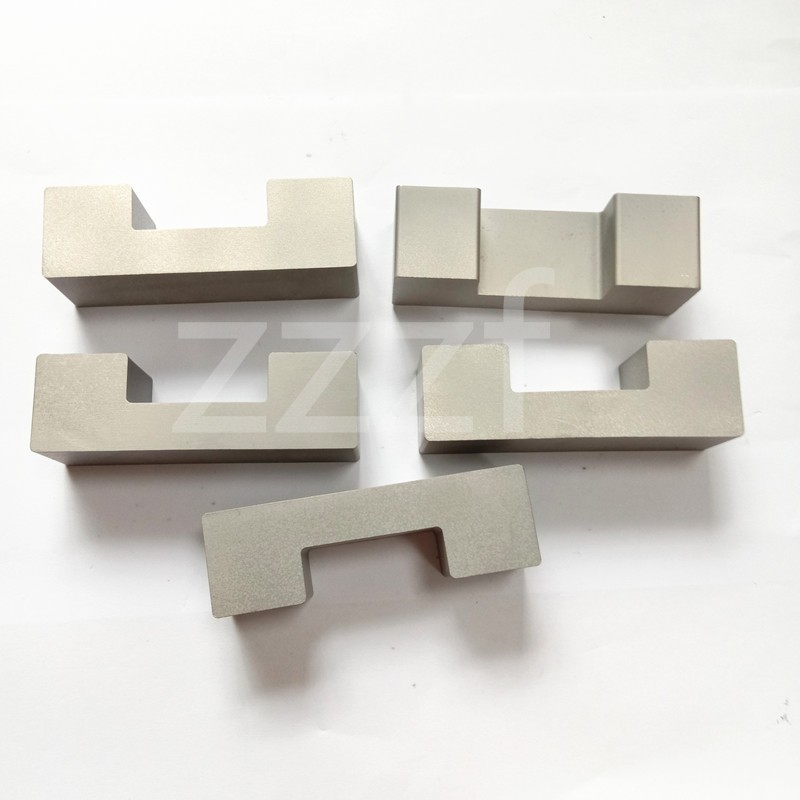

Customized nozzles are available according to your drawing and application.

Our Service:

We can according to customers’ requirement and drawings or sample to process all kinds of fine products, also can help customer in design.

Packing & Shipment

Packing outside carton or plywood case with inner packing

By Express DHL, TNT, FEDEX, UPS, ARAMEX, etc.

We can arrange shipment according to our customers’ requests.

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com