Solid Carbide Rods

HRA92.5 Unground Solid Carbide Blanks Round Rods With Various Hole Size

- Place of Origin: Zhuzhou, China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade:

- Minimum Order Quantity:10 pcs

- Price:negotiable

- Delivery Time:3-15dyas

- Payment Terms:L/C, D/A, D/P, T/T, Western Union

- Supply Ability:15 tons/month

HRA92.5 Unground Solid Carbide Blanks Round Rods With Various Hole Size

HRA92.5 Unground Solid Carbide Blanks Round Rods With Various Hole Size

Various grade for your choice

| Grade | YL10.2 | YG6 | YG6X | YG10X | YG8 | YG15 |

| ISO Range | K25-K35 | K20 | K10 | K35 | K30 | K40-K50 |

| WC+others % | 90 | 94 | 94 | 90 | 92 | 85 |

| Co % | 10 | 6 | 6 | 10 | 8 | 15 |

| Grain Size μm | 0.6 | 0.8 | 0.6 | 0.6 | 0.8 | 0.8 |

| Density g/cm3 | 14.5 | 14.9 | 14.9 | 14.5 | 14.6 | 14.1 |

| Hardness HRA | 92.5-92.8 | 89.5 | 92 | 90 | 89 | 86.5 |

| T.R.S N/mm2 | 3800-4000 | 2150 | 2000 | 2200 | 2200 | 2400 |

| Grade | Application |

| YL10.2 | ultra-fine grain WC+ 10% Coblat, with good Wear resistance and Toughness, strength comparatively higher,suitable for PCB micro drills,for making drills,end mill,reamer,taps,burrs etc. |

| YG6 | Fine Grain WC+6% Cobalt, with Good Wear resistance, used for hard wood,processing original wood,aluminum section bar,brass rod and cast iron. |

| YG6X | ultra-fine grain size with cobalt 6%,with good wear resistance,Suitable for processing Chilled cast iron, heat-resistant alloy steel, and fine process of common cast iron |

| YG10X | ultra-fine grain WC+ 10% Cobalt, suitable for small diameter Micro drill ,vertical milling cutter, rotating file |

| YG8 | fine GrainWC+ 8% Cobalt Suitable for the roughening of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

| YG15 | fine grain WC +15% Cobalt for mining tools, cold heading and punching dies |

Production Advantages

1. we using 100% WC and the raw matearils of CO.

2. High hardness HRA89-93 ,good bending strength TRS 2800-4200.N/mm2

3. Long probation,stamping.

4. Has good wear resitance.

5. Professional manufacturer for more than 10years experience.

6. With the HIP sintered technology,the structure of tungsten carbide is more uniform,more dense,the TRS can be raised more than 20%

7. We make tungsten carbide rods extruded or pressed.

8. Customization is acceped

Application:

Our Solid carbide rod has good straightness, excellent hardness, and stable toughness.With high wear / corrosion resistance, suitable for the manufacturing of various kind of solid cemented carbide tools for the machining of heat-resistant alloy and Ti alloy,also suitable for the manufacturing of micro drills used for machining PCB.

Tungsten carbide rod grades are mostly fine and ultra fine grain with high performance. It's suitable for processing of non-ferrous metal, plastic materials, carbon fiber, chilled cast iron and heat-resistant alloy steel, high-temperature alloy steel, stainless steel, high manganese steel, etc. It can manufacture of drill bits, end mills, and reamers. Tungsten carbide bushing widely used in stamping tools and wear-resistant tools, etc.

| Outside Diameter | OD Tolerance | Inner Diameter | ID tolerance | Length | L tolerance |

| D | Tol | d | Tol | L | Tol |

| mm | mm | mm | mm | mm | mm |

| 2.5 | +0.20~0.50 | 0.3 | ±0.10 | 330 | 0~+5.0 |

| 4.0 | +0.20~0.50 | 1.0 | ±0.15 | 330 | 0~+5.0 |

| 6.0 | +0.20~0.50 | 1.0 | ±0.15 | 330 | 0~+5.0 |

| 8.0 | +0.20~0.50 | 1.5 | ±0.15 | 330 | 0~+5.0 |

| 10.0 | +0.30~0.60 | 2.0 | ±0.20 | 330 | 0~+5.0 |

| 12.0 | +0.30~0.60 | 2.0 | ±0.20 | 330 | 0~+5.0 |

| 14.0 | +0.30~0.60 | 2.0 | ±0.20 | 330 | 0~+5.0 |

| 16.0 | +0.30~0.60 | 2.0 | ±0.20 | 330 | 0~+5.0 |

| 18.0 | +0.40~0.80 | 3.0 | ±0.25 | 330 | 0~+5.0 |

| 20.0 | +0.40~0.80 | 3.0 | ±0.25 | 330 | 0~+5.0 |

| 22.0 | +0.40~0.80 | 3.0 | ±0.25 | 330 | 0~+5.0 |

| 24.0 | +0.40~0.80 | 4.0 | ±0.30 | 330 | 0~+5.0 |

| 26.0 | +0.40~0.80 | 5.0 | ±0.35 | 330 | 0~+5.0 |

We manufactured and stocked unground and ground carbide rods for you. For more size information, please kindly email or call us.

We guarantee:

* We are real factory in Zhuzhou

* Full ability to accept OEM & ODM orders

* Manufactured with100% tungsten carbide raw material

* Comply with ISO 9001:2015 Certification

* Strict inspection for quality of raw material and finished products

* Rich experience of over 10 years

* Advanced technology , automatic pressing , HIP sintering

Our packing and shipping

Based on Detail products, we use different Standard packing suitable overseas shipment.

For carbide rod packing as following

1. outsizde carton or plywood case

2. inner packing is plastic box or small carton with cotton or paper protection

3. Shipping:UPS,TNT,EMS,Fedex,DHL, shipment by sea, or as you request.

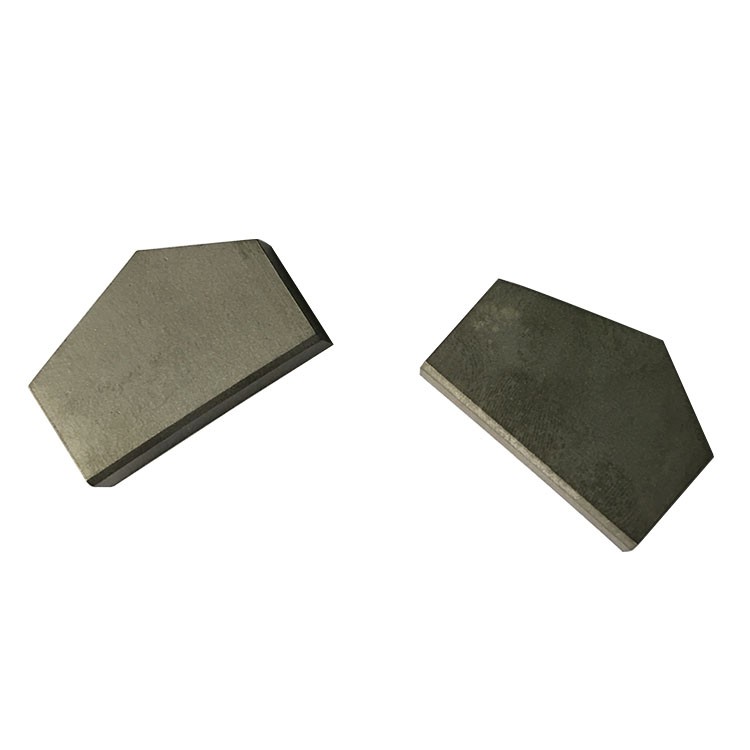

Product Image

For more information, warmly welcome to contact me

Email:shirley@chinahardalloy.com

Mobile:+8617773379950(wechat/whatsapp)

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 6A-block,Tianyikeji industrial park, Qunfeng town, Tianyuan district, Zhuzhou, Hunan, China 412000