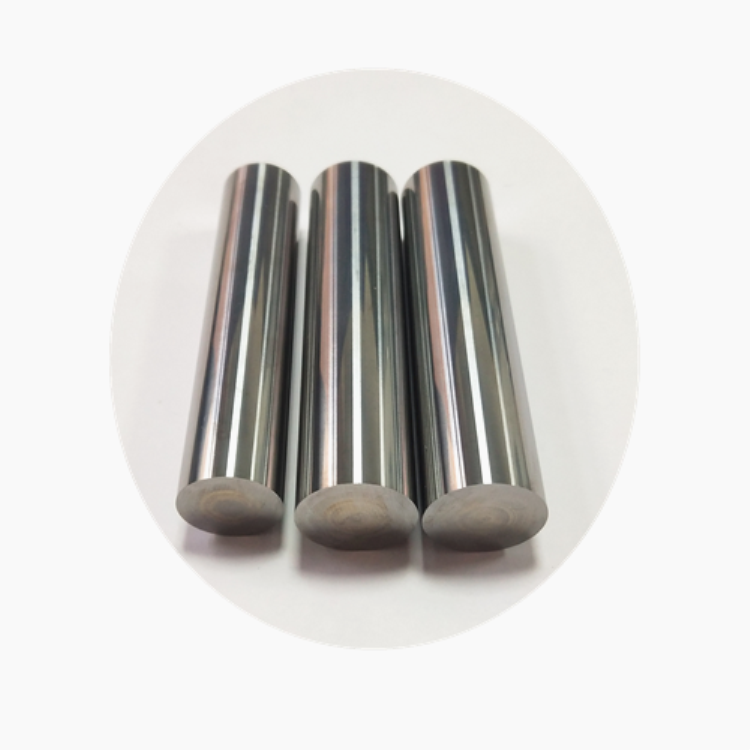

Ground Tungsten Carbide Rod

Customized ground tungsten carbide round rod for end mill

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF0047

- Minimum Order Quantity:10 pcs

- Price:USD 45-58/kg

- Delivery Time:3-5 days

- Payment Terms:100% TT before shiping

- Supply Ability:100000 pcs/month

Customized ground tungsten carbide round rod for end mill

Specifications

1. having all kind sizes for your choose,can suply less than 1000mm length.

2. Sintere by vacuum sintering furnace and HIP machine with excellent specifications without any hole.

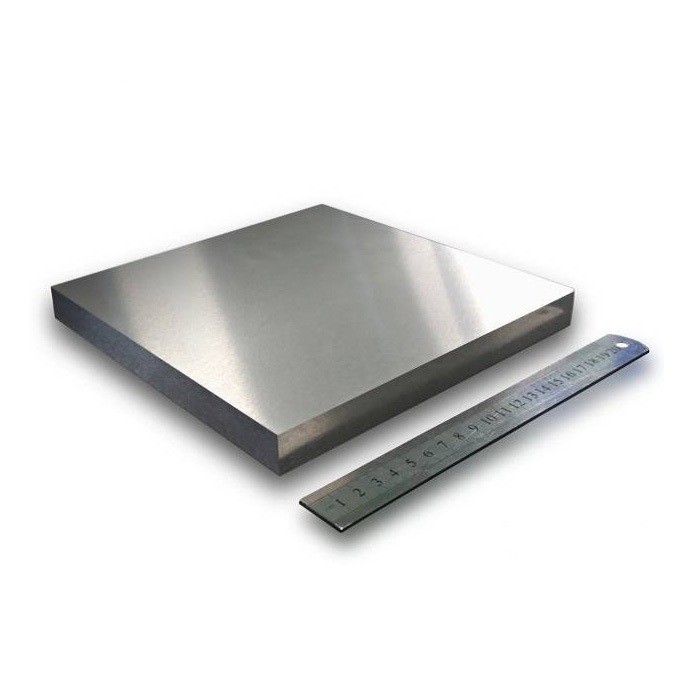

3. suply blank plate with tolerance(-0.15~+0.15)or (0~+0.3).

4. can grinding and polishing the diameter, making chamfer,sharper rod end.

5. process the carbide rod according your request and tolerances.

Grades choosing

Grade | Density(g/cm3) | Hardness (HRA) | T.R.S (MPa) | Grain size (μm) | Composition (%) | Equal to ISO |

| YU12 | 14.1~14.15 | .≥92.5 | ≥4000 | 0.2~0.5 | 12% CO 88% WC | K40~K50 |

YL10.2 | 14.4~14.6 | ≥92.2 | ≥4000 | 0.6~0.8 | 10% CO 90% WC | K20~K30 |

YG6X | 14.85~15.0 | ≥92.0 | ≥3860 | 0.8~1.0 | 6% CO 94% WC | K05 |

YG15 | 14.0~14.1 | ≥85.0 | ≥2800 | 1.2~2.0 | 15%Co 85% WC | K30~K40 |

YG10 | 14.5~14.6 | ≥85.5 | ≥2600 | 1.2~2.0 | 10%Co 90% WC | K20 |

YG8 | 14.65~14.85 | ≥89.5 | ≥2320 | 1.2~2.0 | 8% CO 92% WC | K20 |

YG6 | 14.85~15.05 | ≥90.0 | ≥2150 | 1.2~2.0 | 6% CO 94% WC | K10 |

Sizes choosing

| Diameter(mm) | Length(mm) | grinding and polishing |

| 0.3~1.0 | 5~330 | h6,h7,H6 or H7 |

| 1.0~3.0 | 5~330 | h6,h7,H6 or H7 |

| 4.0~80 | 5~1000 | h6,h7,H6 or H7 |

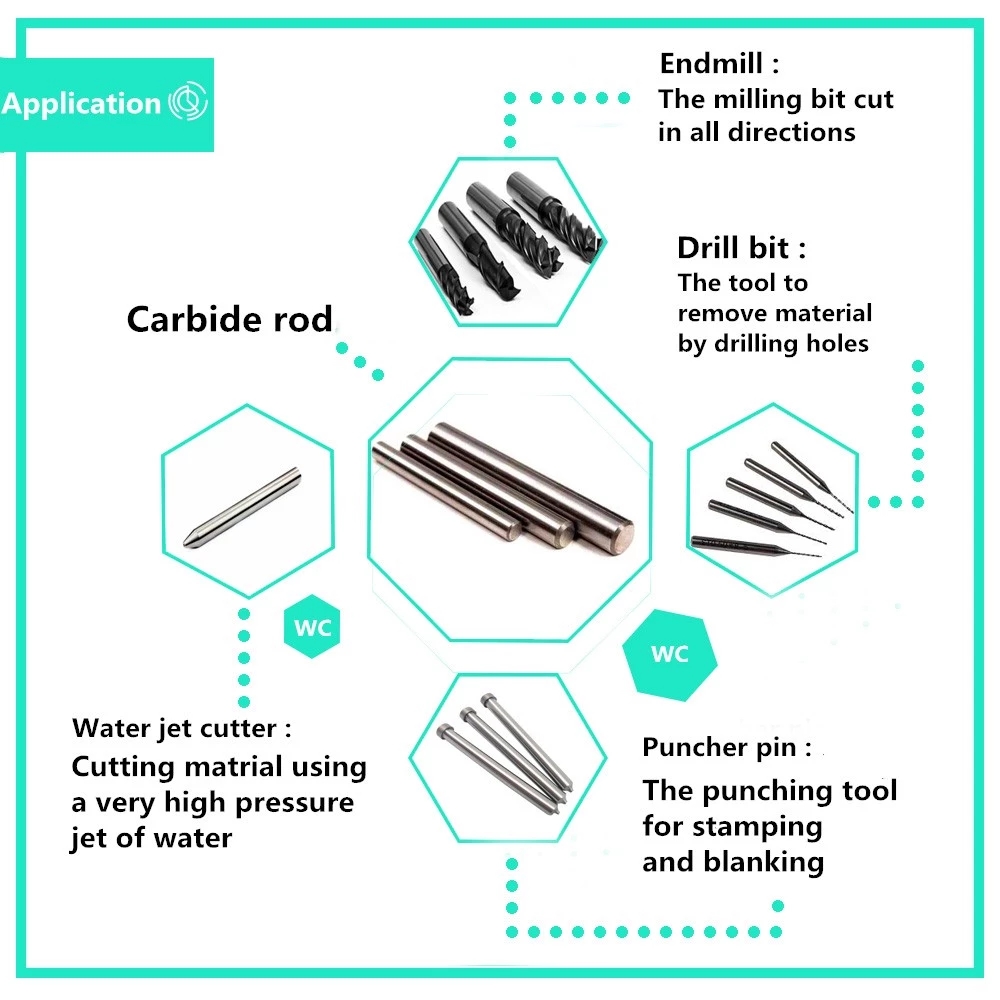

Applications

having high red hardness, good weldability and the characteristics of high hardness, high wear resistance,

mainly used in making solid wood processing, density board, grey cast iron,Non-ferrous metal materials,

chilled cast iron, hardened steel, PCB, brake materials.When using, should according to specific purpose

to choose the right material of tungsten carbide bar.

6. Tungsten Carbide Circular Blade

| Packing | Outside Carton or plywood case with inner plastic box. |

| Shipping | UPS,TNT,EMS,Fedex,DHL,or by sea,as you reques |

If have any more question, please feel free to contact with us.

Contact information

contact person:Ms Sharon Chen

Mobile phone number:+86-18173388506

email address:sharon@chinahardalloy.com

website:www.tungstencarbide-rods.com

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 6A-block,Tianyikeji industrial park, Qunfeng town, Tianyuan district, Zhuzhou, Hunan, China 412000