Custom Tungsten Carbide Parts

YG15 125*82*15 mm tungsten carbide roller for rolling rebars

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: YG15

- Price:Quote based on drawings

YG15 125*82*15 mm tungsten carbide roller for rolling rebars

Material:100% virgin raw material with micro grain size

Tolerance: strict tolerance with extent control

Grades:various of choice YG15,YGR20,YGR25,YGR30,YGR40,YGR45,YGR55,YGR60,YGH30,YGH40,YGH45,YGH55 etc.

Physical Performance:high hardness,excellent wear resistance,good impact resistance and good chemical&mechanical stability

Introduction

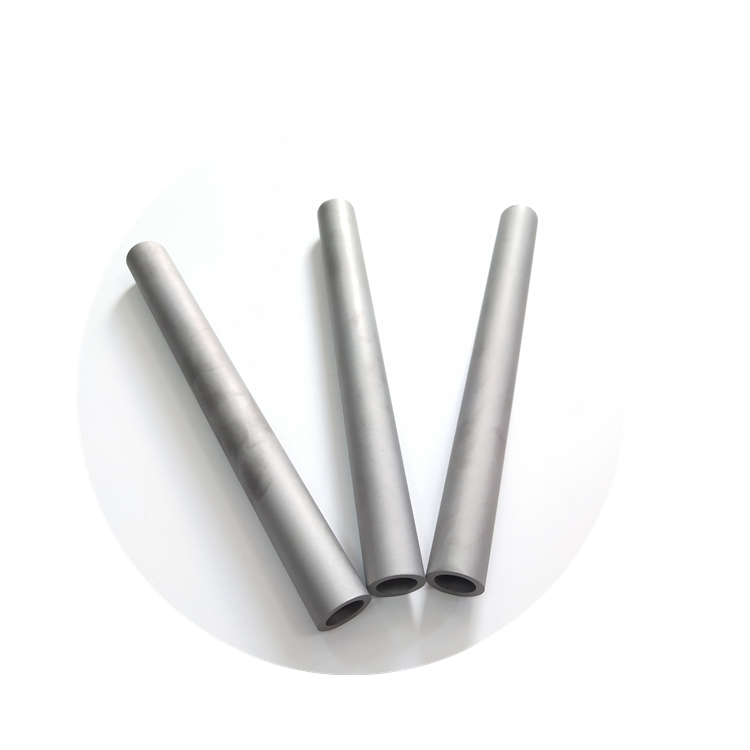

Cemented carbide roll collar (also called tungsten carbide rollers) refers to the roll made from tungsten carbide and cobalt by powder metallurgy. Tungsten carbide rollers are available in both integral and combined versions. They have excellent performance, stable quality, high processing precision, good wear resistance, and high impact resistance.

With the increasingly fierce competition in the quality and price of steel products, steel companies are constantly updating their equipment technology to continuously increase the rolling speed of rolling mills. At the same time, how to reduce the rolling mill downtime and further improve the effective operation rate of rolling mills? It has become an important topic for rolling steel engineers. The use of roll materials with higher rolling life is one of the important means to achieve this goal.

Due to its good wear resistance, high-temperature red hardness, thermal fatigue resistance, and high strength cemented carbide rolls have been widely used in the production of wire rods, rebars and seamless steel tubes, which greatly improved the work efficiency of the rolling mill. A variety of different grades of carbide rings have been developed based on the differences in the working conditions of the different racks and rolls.

Tungsten carbide rollers can be divided into solid carbide rolls and composite hard alloy rolls according to the structure. Solid carbide rolls have been widely used in pre-finishing and finishing stands for high-speed wire rod mills (including fixed reduction racks, pinch roll stands).

The composite cemented carbide roll is made of cemented carbide and other materials and can be divided into hard alloy composite roll ring and solid carbide composite roll. The cemented carbide composite roll ring is mounted on the roller shaft; for the solid carbide composite roll, cemented carbide roll ring is directly cast into the roll shaft to form an entirety, which is applied to the rolling mill with the large rolling load.

Features

Property

The tungsten carbide rollers have high hardness, and its hardness changes very little with temperature changes. The hardness at 700 °C is 4 times that of high-speed steel; and the elastic modulus, compressive strength, flexural strength, and thermal conductivity are also over 1 times higher than tool steel.

Since the thermal conductivity of the cemented carbide roll is high, the heat dissipation effect is good, and the time at which the surface of the roll is at a high temperature is short so that the high-temperature reaction time between the roll and the harmful impurities in the cooling water is short. Therefore, the cemented carbide roll is more resistant to corrosion and cold and hot fatigue than the tool steel roll.

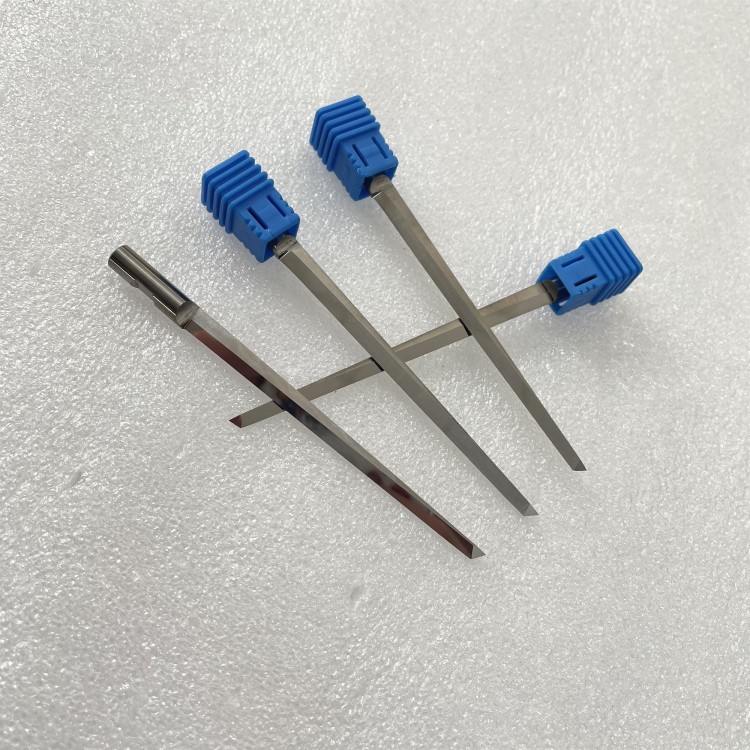

1. Tungsten Carbide rod

2. Tungsten Carbide Sealed Ring

3. Tugnsten Carbide Wear parts

4. Tugnsten Carbide Dies

5. Tungsten Carbide Non-standard parts

6. Tungsten Carbide Circular Blade

We always keep good relationship with our clients, enhancing communication.

Why choose us ?

1.We are a real factory with very very nice wholesale price with high quality and good after sales service.

2.Rearch and development team with 5 members is rich experienced. OEM and label printing

orders are welcome.

3.The MOQ is 1pc.Sample and freight fee is borne by buyer.The sample fee will be reduced in

the next big quantity order.

4.Quick delivery time. We have carbide rods in stock. Delivery time within 3 days after your payment.If quantity is customized and large,delivery time is negociate.

For more information, warmly welcome to contact us

Ms. Sharon Chen

Email:sharon@chinahardalloy.com

Mobile:+8618173388506

Whatsapp:+8613823202651

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com