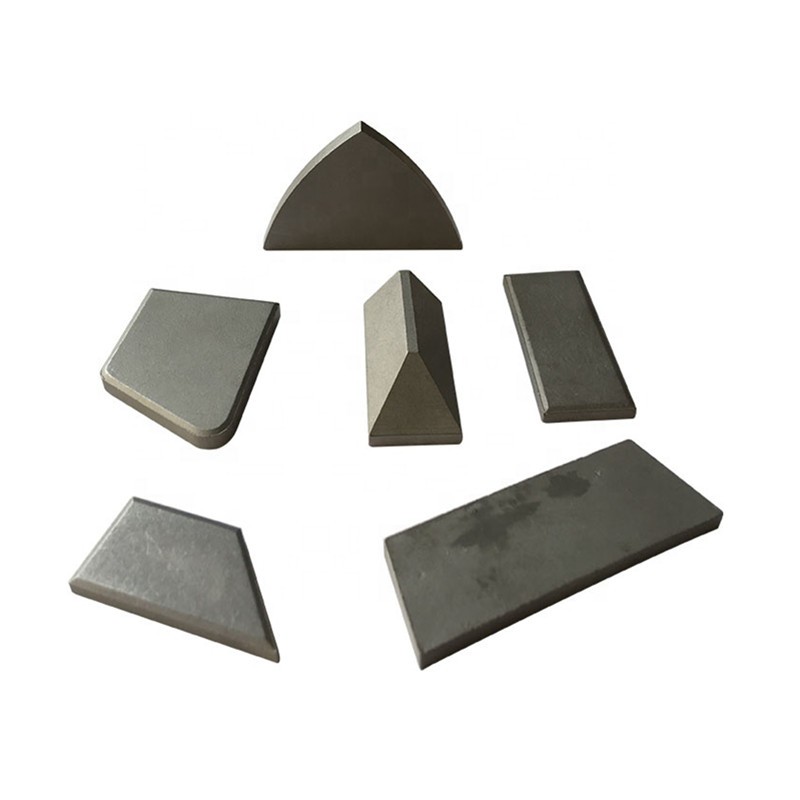

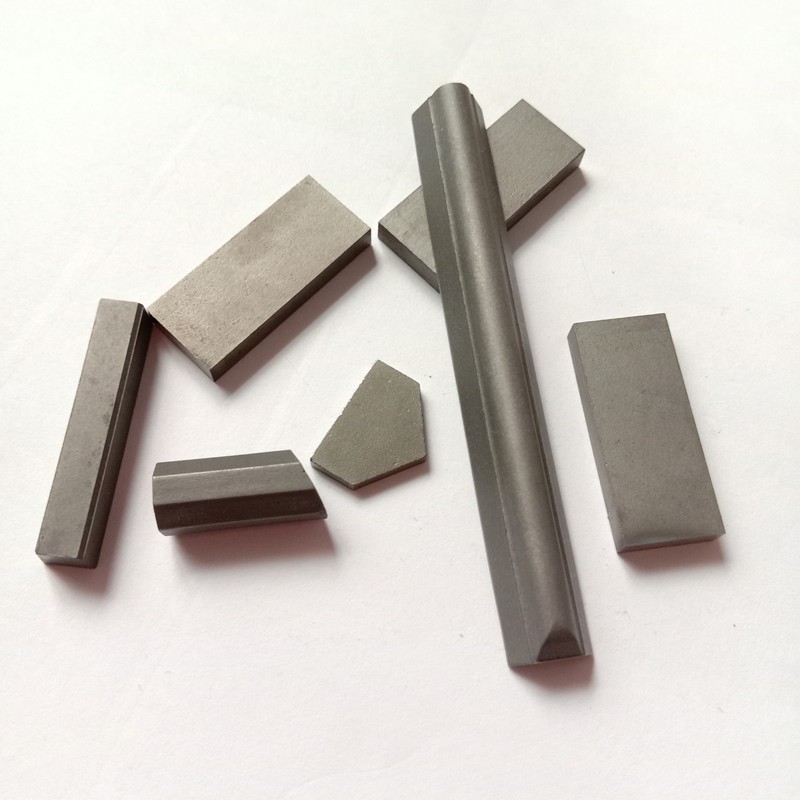

Custom Tungsten Carbide Parts

High Quality Tungsten Carbide Teeth Tine Harrow Tool Wear Tips

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF-C56

- Minimum Order Quantity:10 pcs

- Price:Negotiable

- Delivery Time:3-15days

- Payment Terms:L/C, D/A, D/P, T/T, Western Union

- Supply Ability:15tons/month

High Quality Tungsten Carbide Teeth Tine Harrow Tool Wear Tips

Tungsten carbide tip is made by high quality tungsten carbide raw material, which has the character of high wear resistance and high heat resistance. It's widely supplied to the Agriculture, Railroad, Mining,Oil Sands, Power Generation, Construction, Aggregates, Cement, Waste Management, Transportation, and Recycling Industries with the very best carbide wear resistance in these industries.

Carbide welding tips for the tillage , cultivator , plough. the best grade is YG11,YG8C, YG15,.

we produce carbide agricultural tips according to customer's drawings.

We can produce any type and size carbide plate, tile , teeth for the agriculture tool parts.

Application

Our advantages of Tungsten carbide tips

1. Use 100% tungsten carbide raw material

2. ISO 9001 Certification

3. with 13 years experience in R & D and manufacturing.

4. Advanced technology and equipment , automatic pressing, HIP sintering, and precision grinding.

5. We accept OEM manufacturing and produce on your design.

| YG6 | 14.9 | 90 | 2300 | 6% Co, 94%WC |

| YG8 | 14.7 | 89 | 2400 | 8% Co, 92%WC |

1. outsizde carton or plywood case

2. inner packing is plastic box or small carton with cotton or paper protection

3. Shipping:UPS,TNT,EMS,Fedex,DHL, shipment by sea, or as you request.

For more information, warmly welcome to contact me

Ms. Shirley Pan

Email: shirley@chinahardalloy.com

Mobile:+8617773379950

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

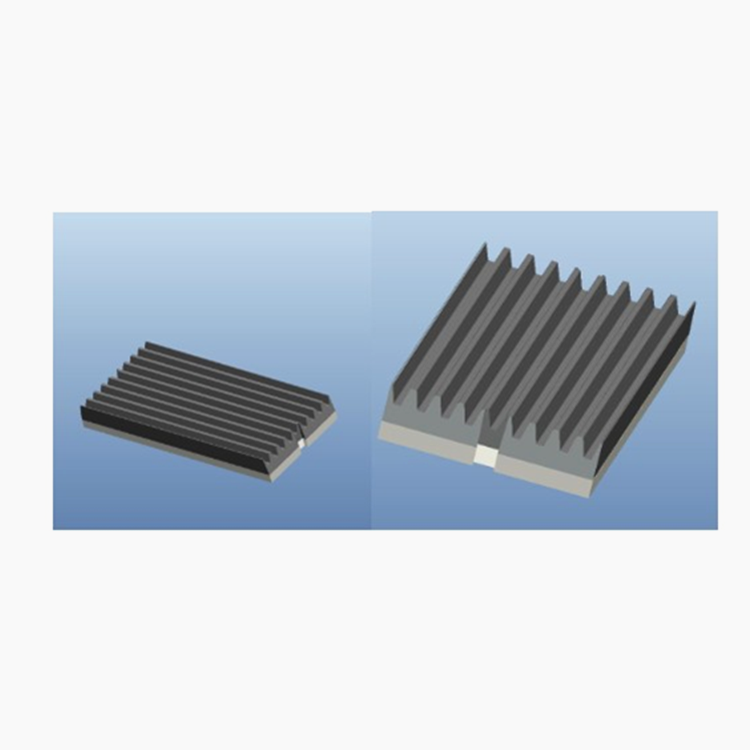

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 7 buildings in area C, High-tech Auto parts City, Zhongda Road, Tianyuan District, Zhuzhou City, Hunan Province.