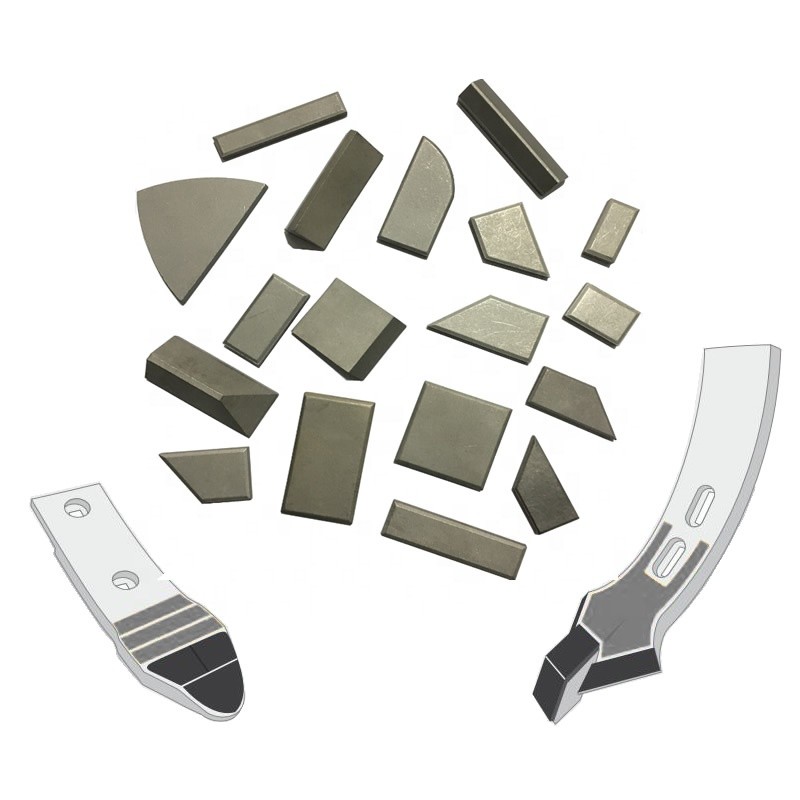

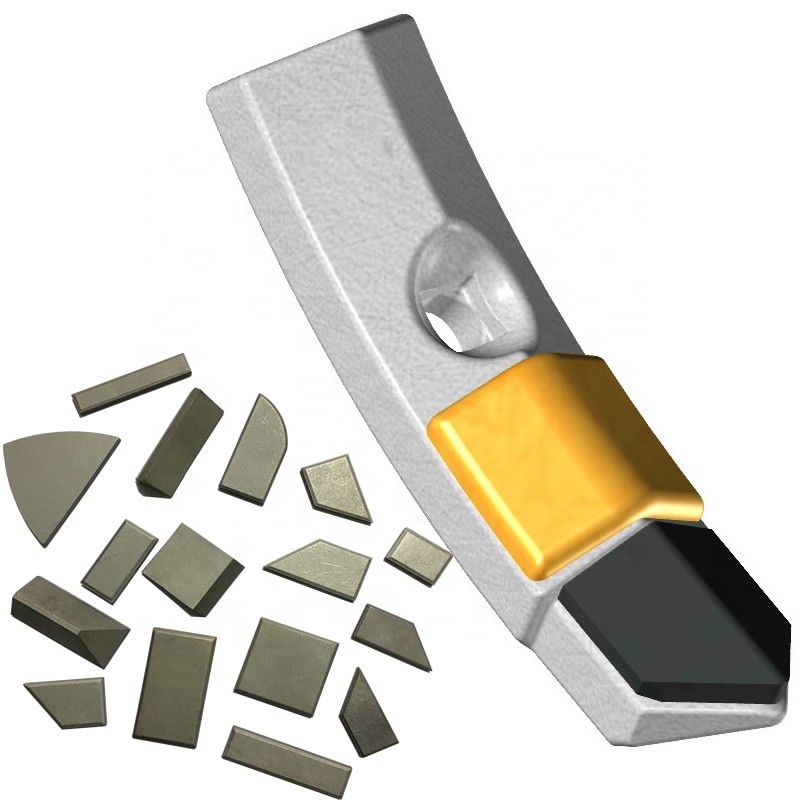

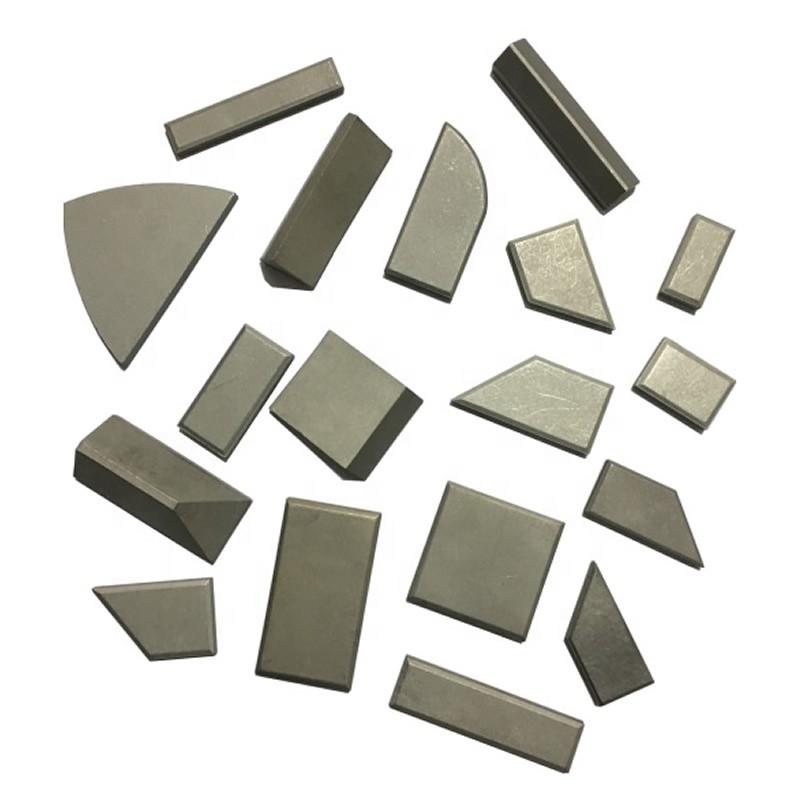

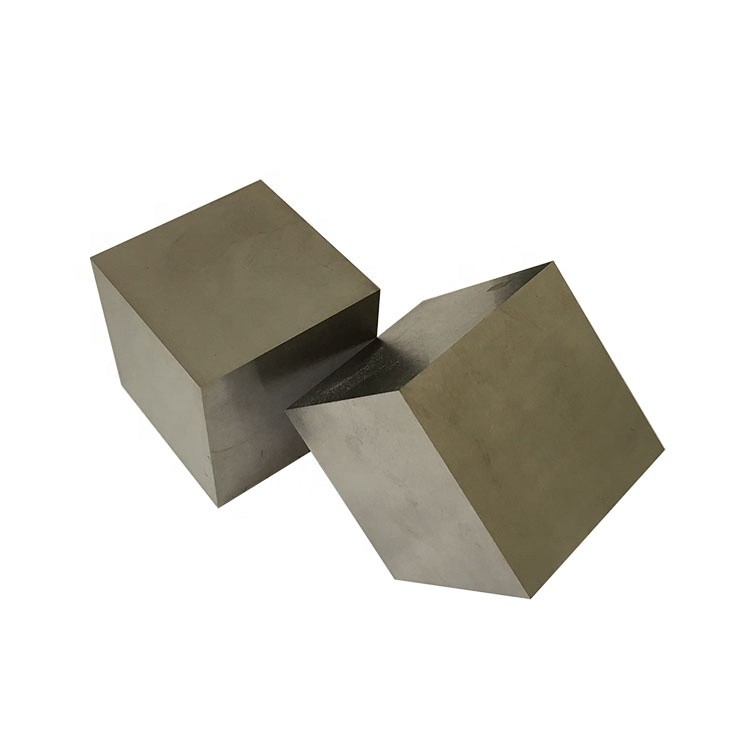

Custom Tungsten Carbide Parts

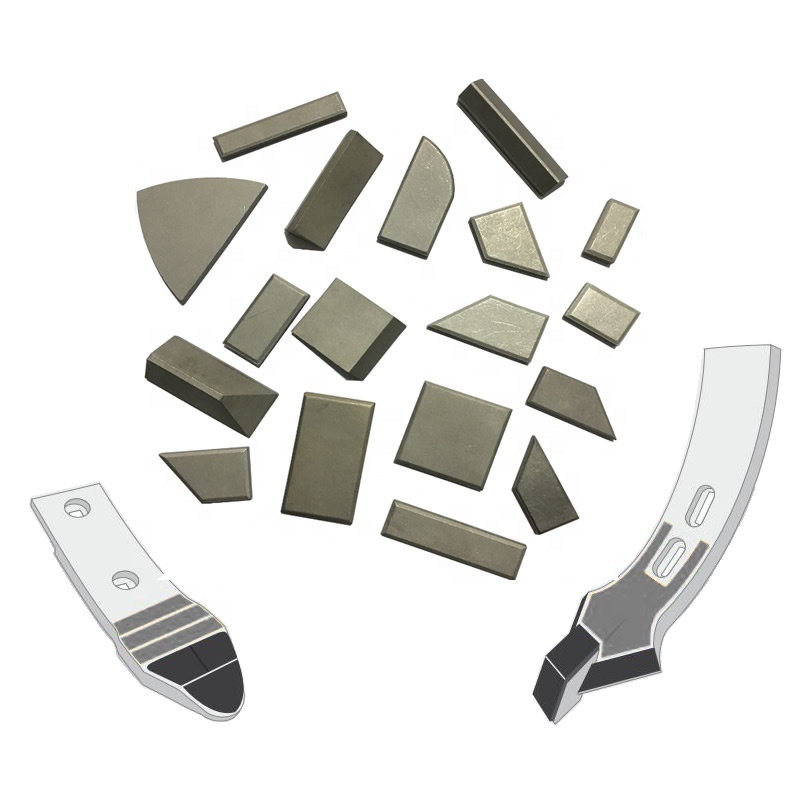

Tungsten carbide points with different size for agriculture soil preparation

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF00123

- Price:Quote based on drawings

Tungsten carbide points with different size for agriculture soil preparation

Description:

Carbide plate for the tillage , cultivator , ploughs the best grade NO is YG11,YG8C, YG15, As some agricultural wear parts have to work in severe environment, so just castig with high strength is not enough, to protect the castings from quick worn , this grade no will greatly increase the serving life.

we are producing carbide agricultural tips according to customer's drawings.

We can produce any type and size carbide plate, tile , teeth for the agriculture tool parts.

Application for Side band , Rumpstad , Tine Fit , Cutivator , Tilllages. Shredder Knives ect.

The grade No is YG15, YG9C

All goods we export to European Countries, US, Austria, France. UK, German, Poland, Newterland. Czech etc.

Our factory got so advantage for price and quality , delivery time.

So welcome any factory who produce these agricuture tool parts ,

Our advantages of Tungsten Carbide Tiles for Agriculture Machinery Wear Parts:

1. Use 100% tungsten carbide raw material

2. ISO 9001 Certification

3. with more than 13 years experience in R & D and manufacturing.

4. Advanced technology and equipment , automatic pressing, HIP sintering, and precision grinding.

5. We accept OEM manufacturing and produce on your design.

6. Tungsten Carbide Circular Blade

Quality control:

1.All raw materials are tested in terms of density, hardness and TRA and HV30 before use

2.Every piece of product goes through in-process and final inspection

3.Every batch of product can be traced

Our Guarantee

1. Competitive price , but good performance.

2. Press by CIP and Sintered in HIP furnace

3. Feedback within 24 hours. More details, please contact us skype/whatsapp: +86-13307338220

4. ISO9001: 2008 certificate professional manufacturer over 20 years

5. Fully adopted in advance technology and equipment.

6. Quality Control System and strict inspection.

7. OEM and ODM are accepted as well.

Our Packing and shipment:

| Packing | Outside Carton or plywood case with inner plastic box. |

| Shipping | UPS,TNT,EMS,Fedex,DHL,or by sea,as you reques |

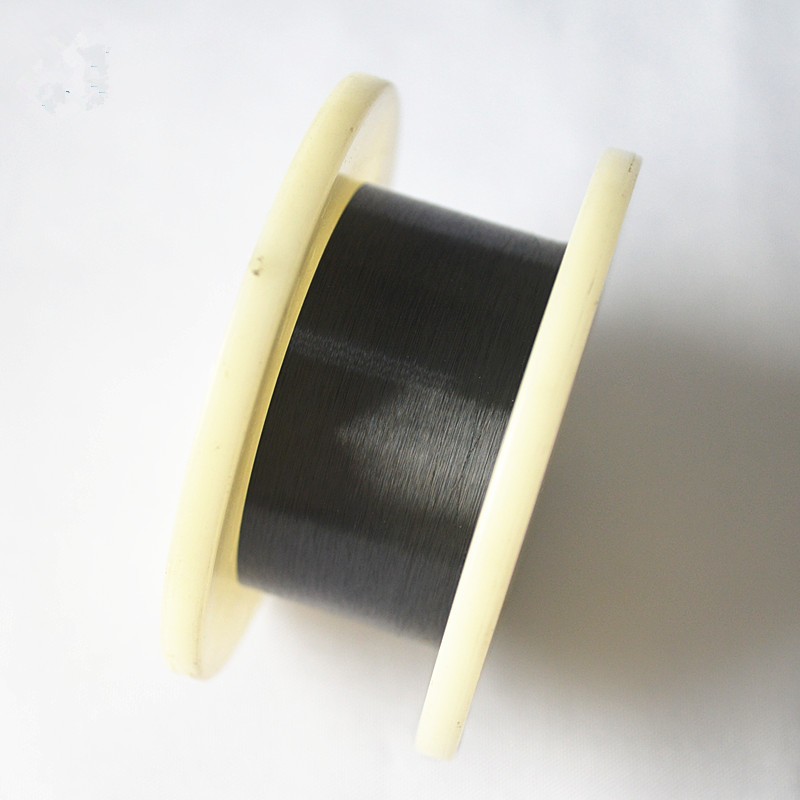

Zhuzhou Zhenfang Yaguang Tungsten-Molybdenum Co.,LTD is a professional manufacture in tungsten carbide field. We have engaged in this field for over ten years. We have rich experience on tungsten carbide studying and manufacture.We pursuit providing efficient solution and high quality products for clients. We specialize in tungsten carbide rod, carbide plate&strips, carbide dies, carbide roller, carbide wear parts for petrochemical industry, carbide cutting tools.Tungsten carbide rod and customized wear parts is our advantage.

We always keep good relationship with our clients, enhancing communication

If have any more information, please feel free to contact with me.

Contact information

contact person: Ms Sharon Chen

mobile number +86 18173388506

email address: sharon@chinahardalloy.com

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com