Cemented Carbide Rods

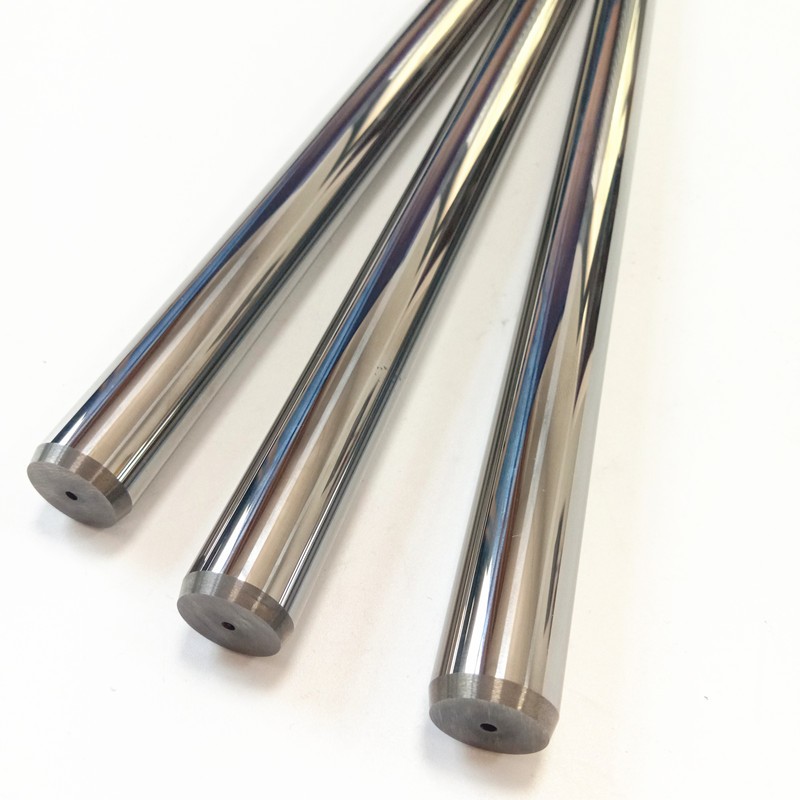

Polished Cemented Carbide Rods , High Performance Tungsten Alloy Rod

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF-R460

- Minimum Order Quantity:10 pcs

- Price:negotiable

- Delivery Time:3-10days

- Payment Terms:L/C, D/A, D/P, T/T, Western Union

- Supply Ability:15tons/month

For more information, please contact me

Shirley Pan

Email:shirley@chinahardalloy.com

Mobile:+86 17773379950(wechat/whatsapp)

Polished Cemented Carbide Rods , High Performance Tungsten Alloy Rod

Application:

1. Tungsten carbide rods are mainly used for making various kinds of solid carbides like PCB micro drill, drill bits, end mill, reamer etc.

2. Tungsten carbide rods can be used for processing aluminum alloy, stainless steel, heat resistant alloy steel, ductile iron, nickel and titanium alloy, nonferrous metal etc.

3. Tungsten carbide rods can also be used for a variety of plug-ins, silicon steel, cold rolled sheet, stainless steel punch, thimble and punch.

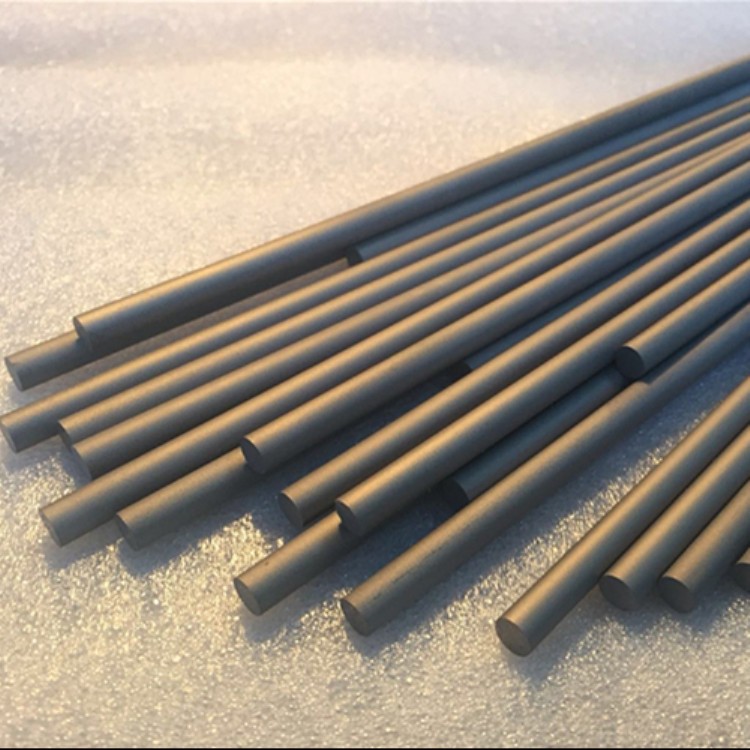

We can supply all kinds of dimensions solid carbide rods with fine&sub micron grain size. We specialized in tungsten carbide round bars with outstanding production line of solid carbide rod and coolant rod.

The tungsten carbide rods we can offer as following:

unground tungsten carbide rod

Ground tungsten carbide rod

Random length carbide rod

Fixed length carbide rod

Carbide rod with one central hole

Carbide rod with chamfer end

Products Details:

1. Size: Dia8x100mm other size also available

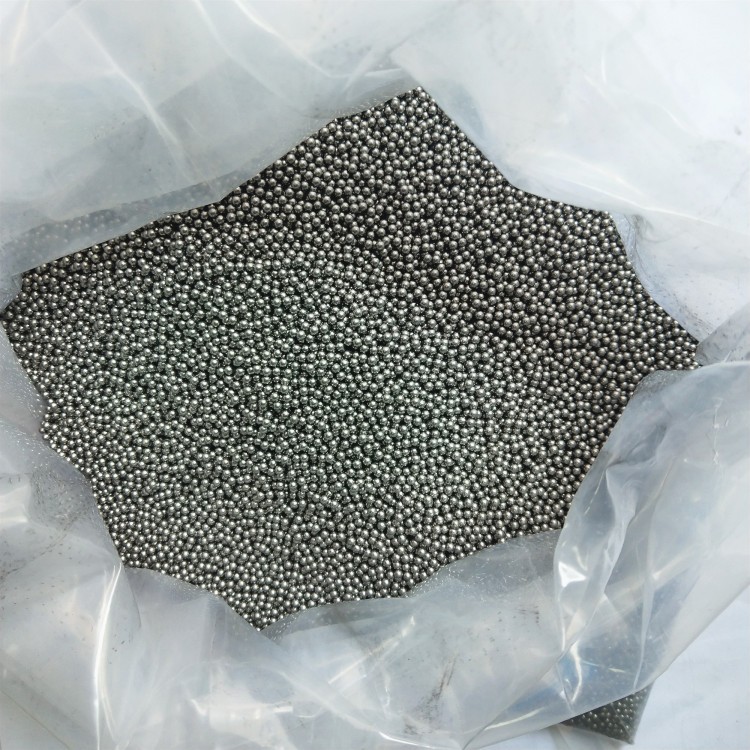

2. Material: Virgin Tungsten Carbide(WC+Co)

3. Grade: YG8/YG6/YG6X/YL10.2

4. Hardness: HRA89/92

5. Surface: Polished

6. Tolerance: h5/h6 based on requirement

7. Grain Size: 0.6-0.8μm

8. Propferties: good abrasive resistance and toughness

Common Unground Dimension and Tolerance

| Dimension | Tolerance of diameter(mm) | Tolerance of length(mm) |

| ZF-Φ1.0x330 | +0.3/+0.5 | +0/+5.0 |

| ZF-Φ2.0x330 | ||

| ZF-Φ3.0x330 | ||

| ZF-Φ4.0×330 | ||

| ZF-Φ6.0×330 | ||

| ZF-Φ8.0×330 | ||

| ZF-Φ10.0×330 | ||

| ZF-Φ11.0×330 | +0.30/+0.70 | +0/+5.0 |

| ZF-Φ12.0×330 | ||

| ZF-Φ14.0×330 | ||

| ZF-Φ16.0×330 | ||

| ZF-Φ18.0×330 | +0.40/+1.0 | +0/+5.0 |

| ZF-Φ20.0×330 | ||

| ZF-Φ22.0×330 | ||

| ZF-Φ24.0×330 | ||

| ZF-Φ26.0×330 | ||

| ZF-Φ28.0×330 | ||

ZF-Φ30.0×330 | ||

| ZF-Φ32.0×330 | +0.7/+1.5 | +0/+5.0 |

| ZF-Φ34.0×330 | ||

We are able to help you customized various diameter and length carbide rod. gound or unground both available | ||

Some grade information for Reference

| Grade | Density g/cm3 | Hardness HRA(hv) | T.R.S (M Pa) | Grain Size(μm) |

| YL10.2 | 14.5 | 92.5 | 3800 | 0.6-0.8 |

| YG6 | 14.9 | 89.5 | 2150 | 0.8-1.2 |

| YG8 | 14.6 | 89 | 2320 | 0.8-1.2 |

| YG11 | 14.4 | 87.5 | 2260 | 0.8-1.2 |

| YG15 | 14.1 | 86.5 | 2400 | 0.8-1.2 |

| YS2T | 14.45 | 92.5 | 2800 | 0.6-0.8 |

| YNi8 | 14.6 | 88.5 | 1710 | 0.8-1.2 |

Our advantage of tungsten carbide rod

* the tolerance of polish and ground can be +0.005/-0.005mm

* We have over ten year experience

* ISO 9001:2015 Certification

* Use 100% tungsten carbide raw material

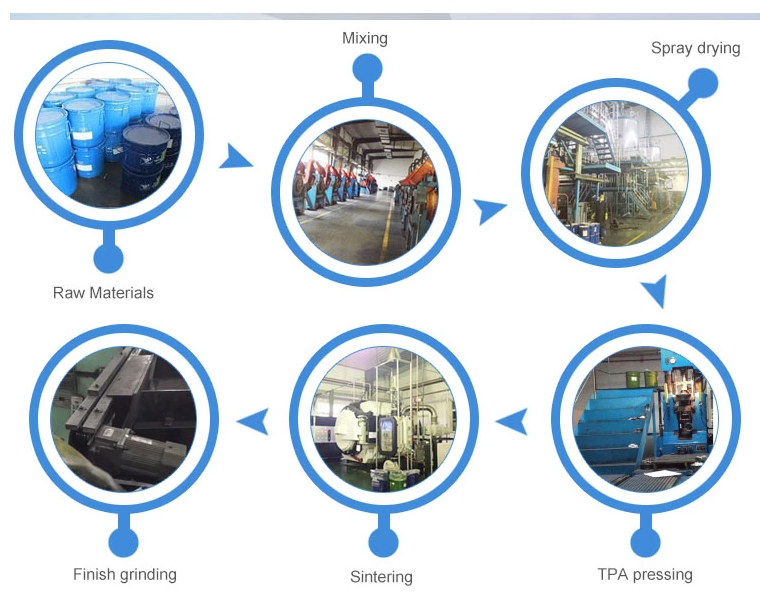

* Advanced technology , automatic pressing , HIP sintering

* Strict inspection for quality of raw material and finished products

* And precision grinding

* Full ability to accept OEM & ODM orders

* Stringent quality control and quality consistency.

Production Process:

Our Packing

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 6A-block,Tianyikeji industrial park, Qunfeng town, Tianyuan district, Zhuzhou, Hunan, China 412000