Carbide Wear Parts

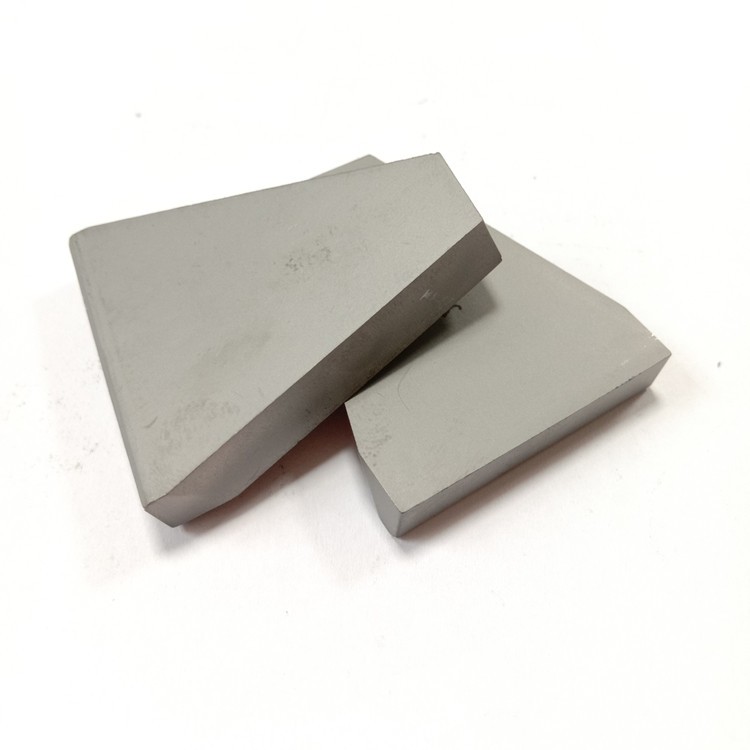

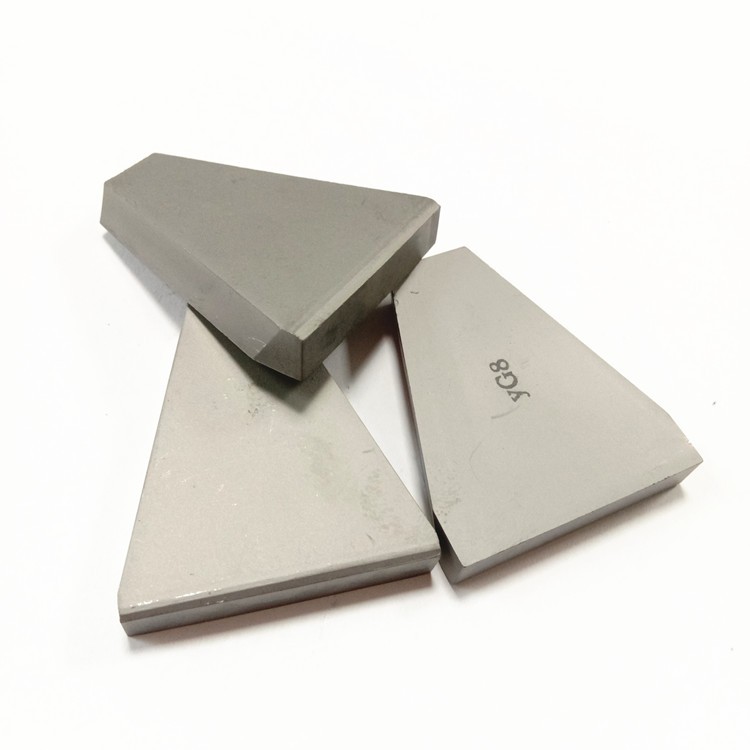

YG6 YG8 YG6X YT5 Cemented Tungsten Carbide Brazed Tips C450

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: K10 K20 K30 YT5 YT15 YW1

- Minimum Order Quantity:10 pcs

- Price:Negotiable

- Delivery Time:3-10days

- Payment Terms:L/C, D/A, D/P, T/T, Western Union

- Supply Ability:15tons/month

YG6 YG8 YG6X YT5 Cemented Tungsten Carbide Brazed Tips C450

The tungsten carbide tips are used for the turning of cast machining, like cast iron, steel, stainless steel,nonferrous metal and nonmetal, etc.

Features:

1. Top 100% virgin raw material

2. Excellent wear-resistance

3. High impact resistance

4. Stable chemical properties

5. Careful surface treatment and perfect appearance

6. Easier to braze, and long service time

7. Made by precision moulds, better diemsional accuracy and uniform

8. Various types and grades available

1.Grade and Application about cemented carbide brazed tips

Grade | ISO Grade | ANSI Grade | Physical and Chemical Property | Performance & Applications | ||

Density | TRS | Hardness | ||||

g/cm3 | n/mm2 | HRA | ||||

YT15 | P10 | C7 | 11.3 | 1650 | 92.0 | Higher wear resistance with a certain impact toughness, Suitable for semi-finishing of medium chip sections, or finishing of small chip sections of steel, cast steel, alloy steel. |

YT14 | P20 | C6 | 11.4 | 1750 | 91.5 | High strength, good impact and shock resistance. Suitable for rough turning, finish milling of carbon steel, and alloy steel during continuous cutting, and semi-finishing and finishing turning during interrupted cutting . |

YT5 | P30 | C5 | 12.9 | 2200 | 90.5 | Best strength, high impact and shock resistance among W-Co-Ti alloys, but comparatively lower wear resistance. Suitable for rough turning, rough planning, and semi-finish planning of carbon steel, and alloy steel including forgings, stamped parts, and cast iron surfaces during intermittent cutting. |

YW1 | M10 | _ | 13.0 | 1710 | 92.5 | Better red hardness, resistant to impact load. A good grade for general purposes. Suitable for machining of ordinary steel, cast irons as well as steels hard to be machined such as refractory steel, high manganese steel, and stainless steel, etc. |

YW2 | M20 | _ | 12.9 | 1880 | 91.0 | Higher wear resistance and strength, resistant to high impact load. Suitable for roughing and semi-finishing of ordinary steel, and cast irons as well as refractory steel, high manganese steel, and high-grade alloy steel, etc |

YG6X | K15 | C3 | 14.9 | 1890 | 91.5 | Fine grain WC alloy, wear resistance higher than YG6, strength close to YG6. Suitable for machining chilled alloy cast irons, and refractory alloy steel, as well as finishing of ordinary cast irons. |

YG6 | K20 | C2 | 14.9 | 2050 | 90.5 | High wear resistance, better impact and shock resistance. Suitable for semi-finishing, and finishing of cast irons, non-ferrous metal, alloys, and non-metallic materials at moderate cutting speed. |

YG8 | K30 | C1 | 14.7 | 2520 | 90.0 | High strength, better impact and shock resistance, but lower wear resistance and cutting speed. Suitable for roughing of cast irons, non-ferrous metal, alloys, and non-metallic materials at low speed |

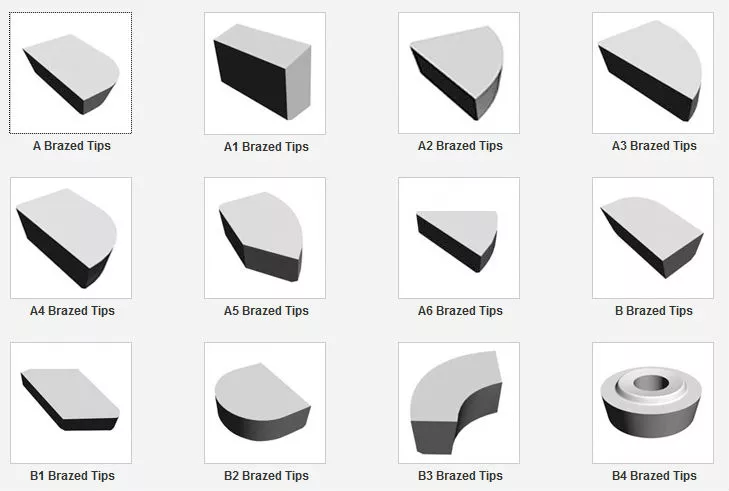

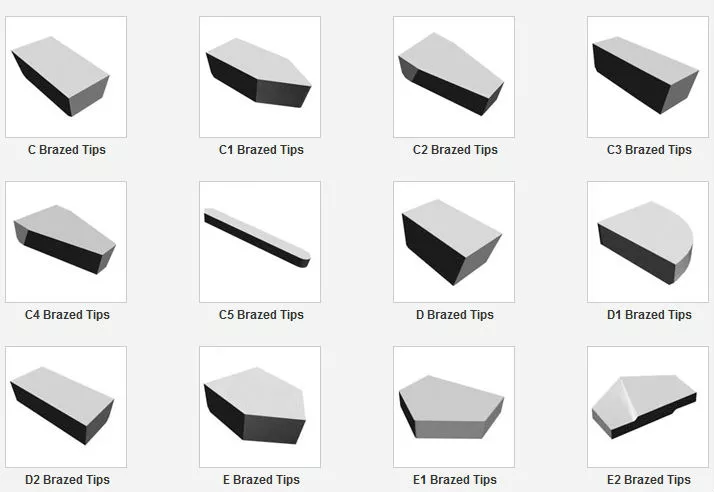

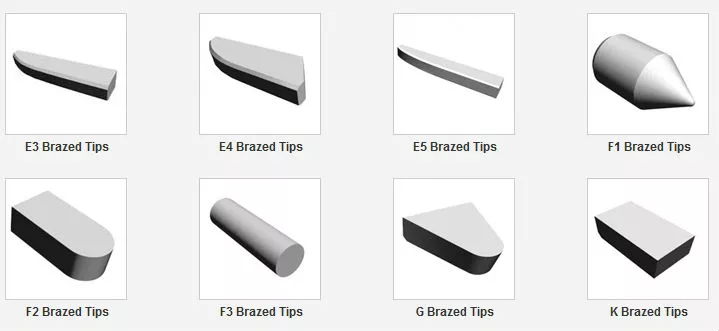

2. carbide brazed tips type

For more information, please feel free to contact us.

Ms. Shirley Pan

Mobile: +86 17773379950(wechat/whatsapp)

Email: shirley@chinahardalloy.com

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 6A-block,Tianyikeji industrial park, Qunfeng town, Tianyuan district, Zhuzhou, Hunan, China 412000