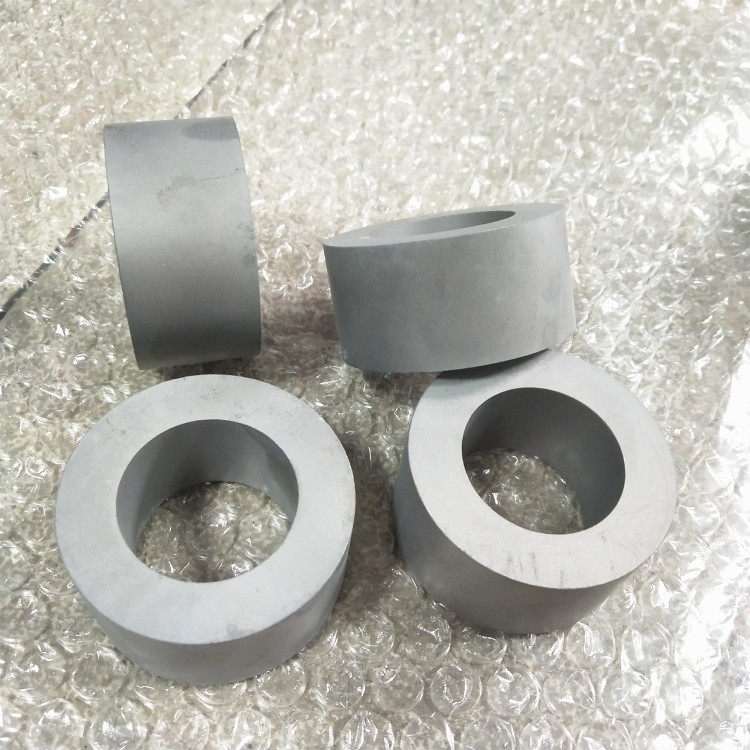

Carbide Wear Parts

YG15 blank tungsten carbide roller for wire drawing and ribbing rolling mill

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: K10,K20,K30

- Price:Quote based on drawings

YG15 blank tungsten carbide roller for wire drawing and ribbing rolling mill

High quality tungsten carbide ribbing rollers with high wear resistance,high bending strength and long service life (1000 metric ton rebars)

Product details

| Item name: | YG15 tungsten carbide roller for wire drawing and ribbing rolling mill |

| Material: | tungsten carbide original material |

| Recommened grade: | YL80.2 / YG15 / YGH30 |

| Application: | rolling mill machine |

| Special service: | OEM and ODM |

| Manufacturer: | since 1998 |

| Enquiry tips: | Drawings,tolerance,roughness and quantity |

| product keywords | YG15 tungsten carbide roller used in wire drawing and ribbing machines |

Brief introduction of tungsten carbide ribbing rollers:

Tungsten carbide ribbing rollers are widely used in steel/rebar works for profiling and forming rebars/bars/wires,due to its high density(14.0-14.2g/cm³),high T.R.S(2800-3200N/mm2) and good wear resistance(hardness 82-86HRA),service life is more than 15 times of traditional steel rolls,carbide ribbing rollers are more and more popular in reinforcement production field,your specific enquiry will be more than welcome.

Our advantages of service:

1.Sales staff beyond 13 years' in this field with good understanding and fluent english.

2.Prompt reply within 24 hours with experienced suggestions.

3.factory cost and short delivery time.

Tungsten carbide rollers can be divided into solid carbide rolls and composite hard alloy rolls according to the structure. Solid carbide rolls have been widely used in pre-finishing and finishing stands for high-speed wire rod mills (including fixed reduction racks, pinch roll stands).

The composite cemented carbide roll is made of cemented carbide and other materials and can be divided into hard alloy composite roll ring and solid carbide composite roll. The cemented carbide composite roll ring is mounted on the roller shaft; for the solid carbide composite roll, cemented carbide roll ring is directly cast into the roll shaft to form an entirety, which is applied to the rolling mill with the large rolling load.

Features

Property

The tungsten carbide rollers have high hardness, and its hardness changes very little with temperature changes. The hardness at 700 °C is 4 times that of high-speed steel; and the elastic modulus, compressive strength, flexural strength, and thermal conductivity are also over 1 times higher than tool steel.

Since the thermal conductivity of the cemented carbide roll is high, the heat dissipation effect is good, and the time at which the surface of the roll is at a high temperature is short so that the high-temperature reaction time between the roll and the harmful impurities in the cooling water is short. Therefore, the cemented carbide roll is more resistant to corrosion and cold and hot fatigue than the tool steel roll.

We always keep good relationship with our clients, enhancing communication.

1.We are a real factory with very very nice wholesale price with high quality and good after sales service.

2.Rearch and development team with 5 members is rich experienced. OEM and label printing

orders are welcome.

3.The MOQ is 1pc.Sample and freight fee is borne by buyer.The sample fee will be reduced in

the next big quantity order.

4.Quick delivery time. We have carbide rods in stock. Delivery time within 3 days after your payment.If quantity is customized and large,delivery time is negociate.

If have any more question, please feel free to contact with us.

contact person:Ms Sharon Chen

Email address:sharon@chinahardalloy.com

whatsapp:+8613823202651

website:www.wmcarbide.com

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com