Carbide Wear Parts

Factory Manufacturing Wear Resistance Spray Tungsten Carbide Nozzle

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: K10 K20 K30 YL10.2 YN8 YN9

- Minimum Order Quantity:10 pcs

- Price:Negotiable

- Delivery Time:3-15days

- Payment Terms:L/C, D/A, D/P, T/T, Western Union

- Supply Ability:15tons/month

For moe information, warmly welcome to contact me

Ms. Shirley Pan

Email:shirley@chinahardalloy.com

Factory Manufacturing Wear Resistance Spray Tungsten Carbide Nozzle

1. 100% virgin raw materials.

2. Various kinds of grades are availalbe based on customer's application.

3. we have professional advanced production line and inspeciton equipments to ensure high quality products.

4. Precision Ground and high polishing process

5. High wear resistance,high hardness and impact toughness

6. Advanced technology , precise grinding.

7.Application: sand blasting, spraying, cleaning

Other application field

We can provide you all kinds of high performance nozzles, such as spray nozzles, oil nozzles, blasting nozzles and so on. With high speed to wash, well wear resistance, excellent corrosion resistance, tungsten carbide nozzles often be used in agricultural irrigation and urban greening. Used in geological prospecting, machinery or tool manufacturing and serves as drill bit in wind drill and electric drills for coal dig. Fit for precision lathe are used in nonstop cutting of die-cast iron.

Grades of carbide nozzle

| Grade | Density g/cm3 | Hardness HRA(hv) | T.R.S (M Pa) | Performances &applications recommended |

| YG6 | 14.9 | 89.5 | 2150 | Good Wear resistance, used for hard wood,processing original wood, aluminum section bar,brass rod and cast iron. |

| YG8 | 14.6 | 89 | 2320 | Suitable for the roughening of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

| YG11 | 14.4 | 87.5 | 2260 | Medium grain, for wear parts and mining tools |

| YL10.2 | 14.5 | 92.5 | 3400 | Wear resistance and strength comparatively higher,suitable for processing cast iron, non-ferrous metal and non-metalloid materials. |

| YN8 | 14.6 | 88.5 | 1710 | This grade with 8% nickel binder, it has good wear resistance& corrosion resistance perfor |

| YN6 | 14.9 | 89 | 1700 | This grade with 6% nickel binder, it has good wear resistance& corrosion resistance perfor |

Cost effective

Good performance property of abrasive resistance

corrosion resistance

stable property performance and long service life.

Customized nozzles are available according to your drawing and application.

Our Service:

We can according to customers’ requirement and drawings or sample to process all kinds of fine products, also can help customer in design

Packing & Shipment

Packing outside carton or plywood case with inner packing

By Express DHL, TNT, FEDEX, UPS, ARAMEX, etc.

We can arrange shipment according to our customers’ requests.

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

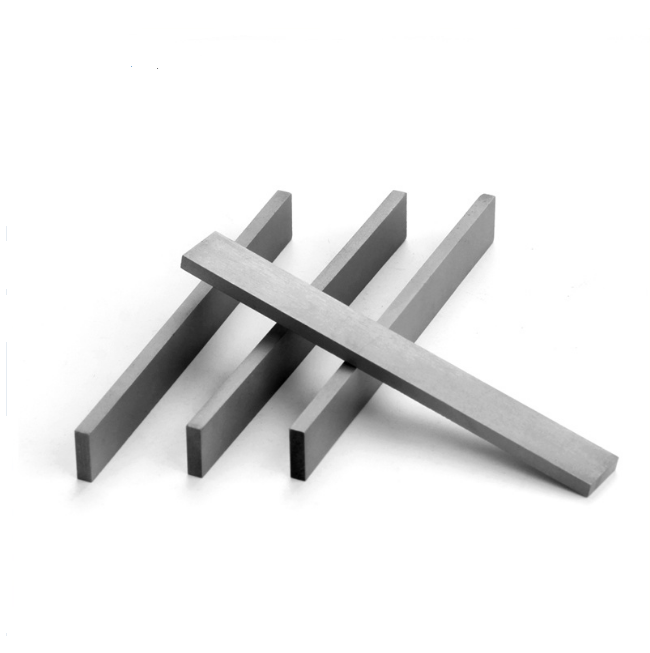

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 6A-block,Tianyikeji industrial park, Qunfeng town, Tianyuan district, Zhuzhou, Hunan, China 412000