Carbide Wear Parts

Resistant Wearing Tungsten Carbide Seal Ring Mechanical Parts ISO Certificate

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF-R025

- Minimum Order Quantity:10 pcs

- Price:

- Delivery Time:3-18days

- Payment Terms:L/C, D/A, D/P, T/T, Western Union

- Supply Ability:15tons/month

Resistant-Wearing Tungsten Carbide Seal Ring Mechanical Parts

We can supply various kinds of tungsten carbide rings , such as dynamic and static rings , the dynamic and static ring is also named sealing rings used for mechanical seal and it also suitable for the equipment which's grinding medium between 0.2 and 0.6mm , grinding & dispersing size between 100 and 500mm

Features of tungsten carbide seal ring :

1. Tungsten carbide rings are the most wear resistant rings available on the planet.

2. Tungsten is about 10 times harder than gold, 5 times harder than tool steel, and 4 times harder than titanium.

3. Due to their extreme hardness, tungsten carbide rings will hold their shapes and shine longer than any ring on the market.

4. Carbide rings have been referred to as the "Permanently polished rings".

5. Carbide rings will NOT bend.

Some grade for tungten carbide sleeve for reference

| Grade | Density (g/cm3) | Hardness (HRA) | Toughness (N=mm2) | Chemical Composition | Performances & Applications |

| YG6 | 14.9 | 89.5 | 2150 | Co 6% | Good Wear resistance, used for hard wood,processing original wood, aluminum section bar,brass rod and cast iron |

| YG8 | 14.6 | 89 | 2320 | Co 8% | Suitable for the roughening of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

| YN6 | 14.8~15 | 90.5 | 2100 | Ni 6% | This grade nickel binder, non-magnetic, it has good wear resistance & corrosion resistance performance, especially used for high pressure environmental |

| YN8 | 14.2 | 91 | 2300 | Ni 8% | |

| YN9 | 14.6~14.8 | 89.5 | 2200 | Ni 9% | |

| YN12 | 14.2~14.4 | 86.5 | 2250 | Ni 12% |

Five essential elements of tungsten carbide priducts

1.high hardness

2. high corrosion resistance

3. strong abrasion resistance

4.long service liftime

5. high bending strength

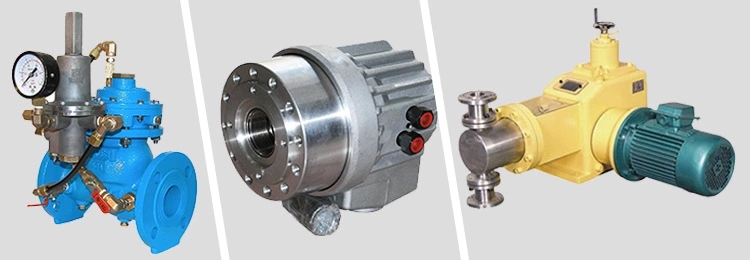

The Application of tungsten carbide seal ring :

The cemented carbide seal-ring can be divided into both of the kinetic seal-ring and static seal-ring, and constitutes mechanic seal together with the spring, rubber seal-ring and steel jecket.

It will be used mainly for waste water pump, water discharge pump for the mines, centrifugal pump, centrifuge, slag slurry pump and slurry pump in the adverse working conditions of high speed rotation, sand flush abrasion and corrosion. The seal-ring will be installed on the pump body and rotating axle, and forms through the end face of the kinetc and static ring a liquid or gas seal.

why you should choose us ?

— We're a mature manufacturer of tungsten carbide products who with over 13 years experience.

— Using HIP sintering technology, which with good densification, high hardness & excellent wear resistance. etc.

— Using German Import antomatic extrusion equipments, the pressure can be adjusted as per the specific requirements. Custom sizes are available (L ≤ 1.4m)— Using 100% virgin fine grain tungsten powder & located in one of the world’s five biggest cemented carbide base -Zhuzhou City.

— Stable quarlity, Timely Delivery with Reasonable Price

— ISO 9001-2008 Quality Control System.

For more information, warmly welcome to contact me by email: shirley@chinahardalloy.com

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 6A-block,Tianyikeji industrial park, Qunfeng town, Tianyuan district, Zhuzhou, Hunan, China 412000