Tungsten Carbide Drill Blanks

Sintered Blank K10 tungsten carbide tube/pipe for thermocouple sleeve

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: YG6, YG8, YL10.2 etc

- Price:Quote based on drawings

Sintered Blank K10 tungsten carbide tube/pipe for thermocouple sleeve

Detailed Product Description

1. Diameter from 0.8 to 42mm.

2. High quality and best price

3. Large stock so the fast delivery

Application

Parts of Electric Light Source and Electron Tube

Medical Facilities

Obstruction of Radiation and Interference

Heat Shields of High Temperature Furnace

Heat Elements of High Temperature Furnace

Structures of High Temperature Furnace

Evaporation Boats

our advantage:

1. Competitive price.

2. Our strengths over other suppliers.

3. Reliable quality on the base of the same price.

4. Timely delivery as your requirements.

5. Professional service to cut much purchasing costs down.

Service

We supply various material grades includes standard YG8, YG6, YG6X, etc. Using good carbide is like using thin kerf saw blades.

The differences are not dramatic but they are important. Good carbide will reduce breakage and give better quality cuts overall.

There are several types of Carbide, including advanced grades. Our R&D Team can supply you with more information about these advanced grades and tungsten carbide grades when you make the inquiry.

Detail Production Information:

YT5 has the best strength, impact resistance and seismic resistance, but poor wear resistance. It is suitable for roughing and

semi-finishing of carbon steel and alloy steel (including forgings, stampings and cast iron skins) when they are cut

intermittently.

YT14 has the advantages of high strength, good impact resistance and seismic resistance, nearly inferior to YT5 alloy, but its

wear resistance is better than YT5. It is suitable for rough turning and rough milling of carbon steel and alloy steel in

continuous cutting, semi-finishing turning and finishing turning in discontinuous cutting.

YG3X has the best wear resistance but poor impact toughness in tungsten cobalt titanium alloy. It is suitable for high-speed

finishing of small sections of cast iron non-ferrous metal and its alloy, pyroclastic steel and alloy steel.

YG6 has higher wear resistance, but lower than YG3, better impact resistance and vibration resistance than YG3X. It is suitable

for semi-finishing and finishing of cast iron, non-ferrous metals and alloys with medium cutting speed.

YG8 has higher strength, impact resistance and seismic resistance than YG6, but its wear resistance and allowable cutting speed

are lower. It is suitable for low-speed rough machining of cast iron, non-ferrous metals and alloys.

Yd201 is suitable for semi-finishing, rough machining of cast iron and light alloy, and milling of cast iron and low alloy steel.

Yw1 has a good red hardness and can bear a certain impact load. It is a universal alloy suitable for the processing of refractory

steel such as heat-resistant steel, high manganese steel and stainless steel, and also suitable for the processing of ordinary steel and cast iron.

Key Features:

1.High melting point (3410°C)

2. low thermal expansion

3.High resistance

4. Vapor pressure is low

5. Good thermal conductivity

6. High density

Our more products

1. Tungsten Carbide rod

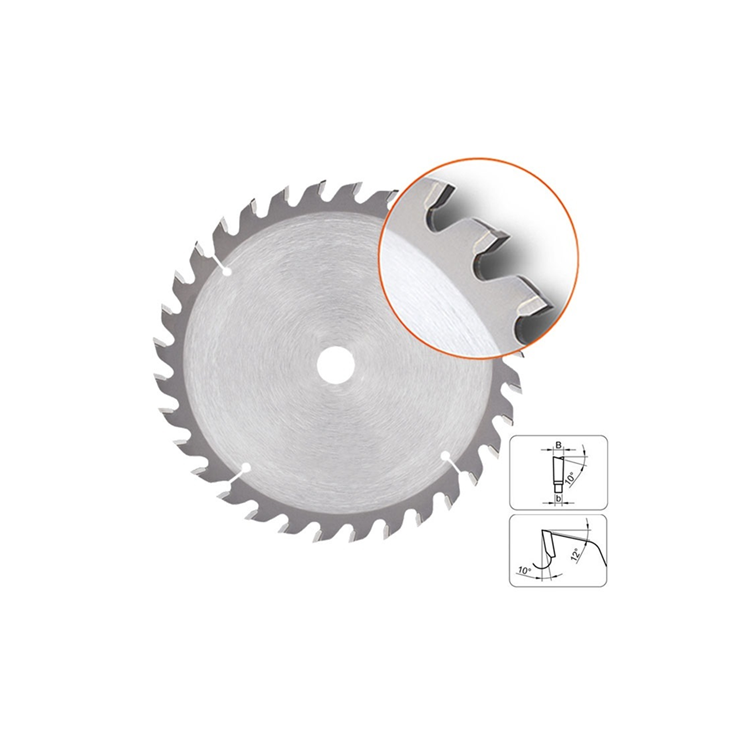

6. Tungsten Carbide Circular Blade

Quality control:

1.All raw materials are tested in terms of density, hardness and TRA and HV30 before use

2.Every piece of product goes through in-process and final inspection

3.Every batch of product can be traced

Our Guarantee

1. Competitive price , but good performance.

2. Press by CIP and Sintered in HIP furnace

3. Feedback within 24 hours. More details, please contact us skype/whatsapp: +86-13307338220

4. ISO9001: 2008 certificate professional manufacturer over 20 years

5. Fully adopted in advance technology and equipment.

6. Quality Control System and strict inspection.

7. OEM and ODM are accepted as well.

Our Packing and shipment:

| Packing | Outside Carton or plywood case with inner plastic box. |

| Shipping | UPS,TNT,EMS,Fedex,DHL,or by sea,as you reques |

Zhuzhou Zhenfang Yaguang Tungsten-Molybdenum Co.,LTD is a professional manufacture in tungsten carbide field. We have engaged in this field for over ten years. We have rich experience on tungsten carbide studying and manufacture.We pursuit providing efficient solution and high quality products for clients. We specialize in tungsten carbide rod, carbide plate&strips, carbide dies, carbide roller, carbide wear parts for petrochemical industry, carbide cutting tools.Tungsten carbide rod and customized wear parts is our advantage.

We always keep good relationship with our clients, enhancing communication

If have any more information, please feel free to contact with me.

Contact information

contact person: Ms Sharon Chen

mobile number +86 18173388506

email address: sharon@chinahardalloy.com

website:www.wmcarbide.com

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com