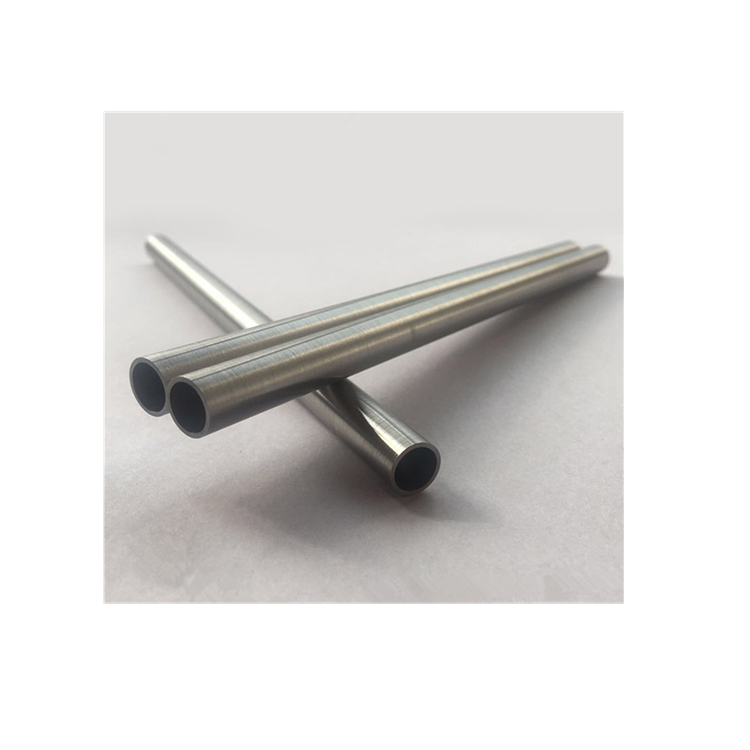

Solid Carbide Rods

K10, k20 dia 14x330mm Grinding Carbide Tungsten Rods cemented carbide Round Bar

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: K10,K20,K30

- Price:Quote based on drawings

K10, k20 dia 14x330mm Grinding Carbide Tungsten Rods cemented carbide Round Bar

1.With strict tolerance extent control

2.Enjoy excellent wear resistance & high toughness

3.Have very good thermal & chemical stability

4.Anti-deformation & deflection

5.A special Hot Isostatic Press (HIP) process provides quality improvement to the finished products to ensure meterial reliability.

Welcome your enquiries.

Also we can send you some samples for your testing.

Advantages of our tungsten carbide rods:

Carbide Rods are used for cutting aluminum alloy, cast iron, stainless steel, refractory alloy steel, nickel based alloy, titanium alloy and nonferrous metals. With several years’ development, with our good quality and competitive price, our products have been widely recognized by worldwide makers of tools. We are looking forward to establish new business with new customers.

The below grades are listed for your reference:

| Grade | Density g/cm3 | Hardness HRA (hv) | T.R.S (MPa) | Performances &applications recommended |

| YG6 | 14.9 | 89.5 | 2150 | Good Wear resistance, used for hard wood,processing original wood, aluminum section bar,brass rod and cast iron. |

| YG8 | 14.6 | 89 | 2320 | Suitable for the roughening of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

| YG11 | 14.4 | 87.5 | 2260 | Medium grain, for wear parts and mining tools |

| YG15 | 14.1 | 86.5 | 2400 | Medium grain, for mining tools, cold heading and punching dies |

| YS2T | 14.45 | 92.5 | 2800 | Fine carbide,high wear resistance,high bending strength,high resistance to bonding, high thermal strength.Machining of refractory alloys, stainless steel and high manganese steel etc.Mainly used for disc cutter and other tools |

| YL10.2 | 14.5 | 92.5 | 3400 | Wear resistance and strength comparatively higher,suitable for processing cast iron, non-ferrous metal and non-metalloid materials |

| YNi8 | 14.6 | 88.5 | 1710 | This grade with 8% nickel binder, it has good wear resistance& corrosion resistance performance ,especially used for high pressure environmental , also good for cutting the titanium alloy. |

Other grades can be supplied by your request.

Usage:

carbide rods used for making the drill bits/ end-mills / reamers .automobile special cutters, printed circuit board special cutters, engine special cutters, Horologe processing special cutters, integral vertical milling cutter, graver and etc. Besides, they can be used for making of cemented carbide stamping head, Core bar and perforation tools.

Your drawings are pretty welcomed.

Application Are

As tungsten carbide have good material properties, it is widely used in varous industries:Paper, packaging, printing, non-ferrous metal processing industry,Mechanical, chemical, petroleum, metallurgy, electronic and natioanl defense industries.

tungsten carbide rods process, to ensure high quality, we commit our customers that:

1. All materials are tested in terms of purity ,density, hardness and T.R.S before use.

2. Every piece of product is inspected before shipment

1. produced with advanced equipments and process.

2. high quality durable tungsten carbide rod blanks/cemented rods for milling for router bits made from 100% virgin raw material.

3. all products go through in-process and final inspection.

4. Quality Control System and strict inspection.

5. stable and continuous production ability.

6. free online technical service available.

7. OEM and ODM are accepted as well.

8. Our solid carbide rods are known for constantly providing maximum quality. You can rely on our products as a basis for

consistent performance capacity of your tools.

9. Undertake orders of non-standard sizes at customer's requests.

For tungsten carbide rod,we can make various type

* solid carbide rod

* grinding carbide rod

* blank carbide rod

* carbide rod with chamfer

* carbide rod with single hole

* custom carbide rod

* carbide rod with tap

Our factory

Zhuzhou Zhenfang Yaguang Tungsten-Molybdenum Co.,LTD is a professional manufacture in tungsten carbide field. We have engaged in this field for over ten years. We have rich experience on tungsten carbide studying and manufacture.We pursuit providing efficient solution and high quality products for clients. We specialize in tungsten carbide rod, carbide plate&strips, carbide dies, carbide roller, carbide wear parts for petrochemical industry, carbide cutting tools.Tungsten carbide rod and customized wear parts is our advantage.

We always keep good relationship with our clients, enhancing communication

FAQ

Q1.What is your advantage ?

A:We have the best factory to produce for you,could guarantee the price is the most competitive. BEGUN carbide was recognized by market, it widely used for Chinese big project,such as subway,high speed rail,tunnel,mining and so on.At the same time,many big projects of the South africa,America,European and Austria also choose our carbide.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% balance before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3.Could you offer OEM and ODM service?

A:That is ok ,we have more than 5 years experience in OEM service.professional R&D department is ready to design products to fit your specifications,they can offer the professional advice and CAD drawings(3D) for you!

Q4. How about your delivery time?

A: Lead time as fast as 7-15 days!

Q5. What is the MOQ ?

A.No MOQ for our existing stock,for special size,MOQ is 5 KGS.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.Our production is based on ISO9001,we have more than 10 years experience of QC team and strictly quality control system in our production process.

Q8. What about the package?

A.It can make as the you need and depend on the products shapes. Generally, we can provide iron drum, carton, wooden case, and bag packages.

Q9: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Customer Notice

To save your value time, please inform us of the following information:

1. Grade

2. Type/Dimension/Clear Drawing

3. Available tolerance

4. Order quantity

5. Blanks or finished products

6.If you have any special requirements of the products, pls send us in advance. We will satisfy you as much as we can.

Pls feel free to contact us you have any requirments, any inquiry is welcomed!

Contact person:Ms Sharon Chen

Whatapp:+86 13823202651

WeChat;18173388506

Email address:sharon@chinahardalloy.com

Website:www.wmcarbide.com

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com