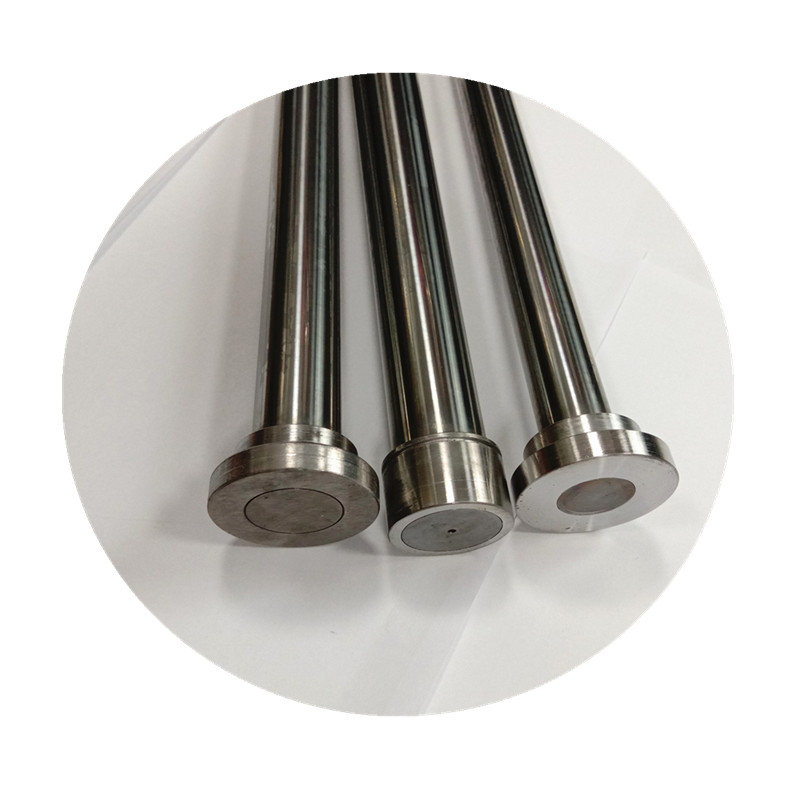

Plunger

Ground Tungsten Carbide Plunger High Precision For High Pressure Pump

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF-R469

- Price:Quote based on drawings

For more iformation, warmly welcome to contact me

Shirley Pan

Email:shirley@chinahardalloy.com

Mobile: +8617773379950(wechat/whatsapp)

Ground Tungsten Carbide Plunger High Precision For High Pressure Pump

Application Range:

our cemented carbide plunger widely used in high pressure pump, high pressure cleaning pump, High-power high-pressure pump group, High Pressure Pump Automatic Set,Pipe dredge, High-pressure oil injection machinery etc.

Detail Information

-. Material: WC+Ni or WC+Co Grade:YN8 (8% Ni)

-. Hardness: HRA89 Bending strength:3500

-. Size: Dia25*277mm Customized

Grade | Density(g/cm3) | Hardness(HRA) | Toughness(N/mm2) | Composition |

YG6 | 14.9 | 89.5 | 2150 | Co 6% |

YG8 | 14.6 | 89 | 2320 | Co 8% |

| YG11 | 14.5 | 87 | 2100 | Co11% |

YN6 | 14.8-15 | 91 | 2100 | Ni 6% |

YN8 | 14.2 | 90.5 | 2300 | Ni 8% |

YN9 | 14.7 | 89.5 | 2200 | Ni 9% |

YN12 | 14.3 | 86.5 | 2250 | Ni 12% |

Our advantage:

1. Material: using high quality raw material

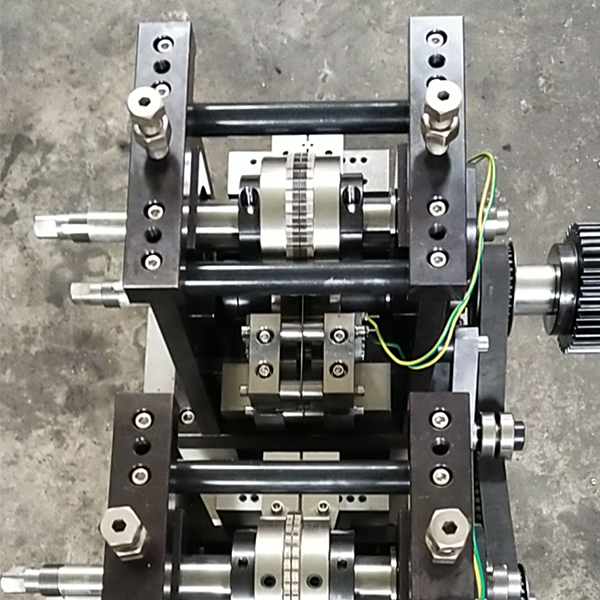

2. Production Procedure: Powder preparing- Pressing-HIP sintering- Processing-Finishing

3. Perfect quality control systerm: ISO9001:2015

4. Various dimension for choosing

5. Various grade for choosing based on your application. the hardness is from HRA82 to HRA92.5

6. We also accept manufacturing based on your drawing

7. We have professional technician team and sales team, giving you professional suggestion

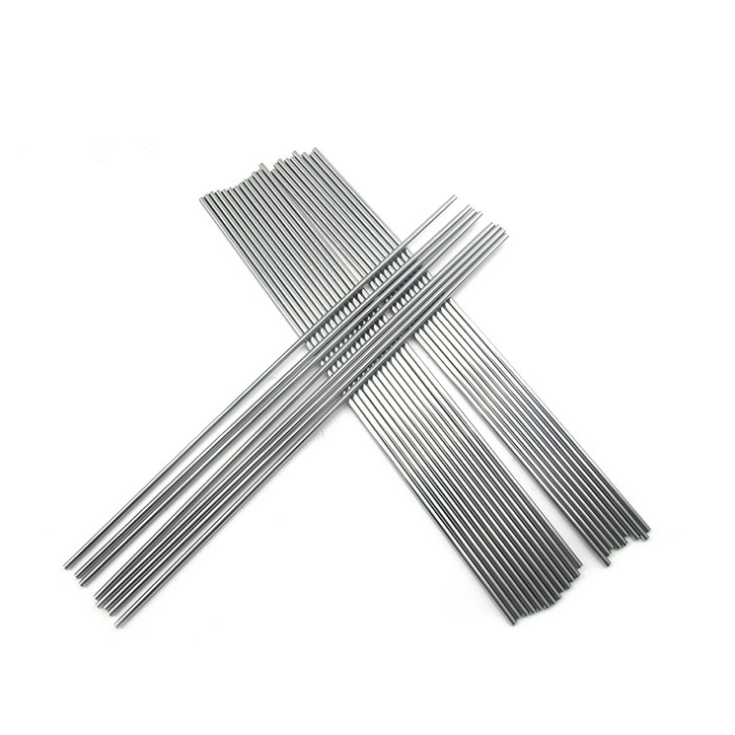

We can supply all kinds of dimensions solid carbide rods with fine&sub micron grain size We manufactured and stocked many dimensions of ground and unground carbide rod for your. We have a large range of grade for your choice. We also can develop grade based on your application.

We offer:

pressed and extruded unground, ground and polished rods with or without chamfers

rod products that can be ground to h6 tolerances

carbide rod with one or two parallel holes

a variety of grades that provide exceptional wear and impact resistance

grades for use in end mills, reamers, drills, countersinks, engraving tools, routers, and other rotary tools

grades for use in a broad range of applications in almost any material

grade for stamping /colding/ forging dies

We make tungsten carbide rods extruded or pressed.

Diameter from 0.3mm to 40mm,

length in 310mm, 330mm or 340mm.

Grade inYL10.2, K10, K20 K30, K35 or etc.

Production Advantages

1. we using 100% WC and the raw matearils of CO.

2. High hardness HRA89-93 ,good bending strength TRS 2800-4200.N/mm2

3. Long probation,stamping.

4. Has good wear resitance.

5. Professional manufacturer for more than 10years experience.

6. With the HIP sintered technology,the structure of tungsten carbide is more uniform,more dense,the TRS can be raised more than 20%

7. We make tungsten carbide rods extruded or pressed.

8. Customization is acceped

Production Process:

Power mixing-Pressing-HIP sintering-Blank- Processing- Finished

Other Application industries:

The carbide rods be widely used in

- metal Working industry

- motorcycle manufacturing industry

- electronin industry

- other mold

- mechanical manufacturing industry

- military defense Industry

- jewelry

Some key areas where cemented carbide components are used:

Automotive components

Rotary cutters for high-speed cutting of artificial fibres

Metal forming tools for wire drawing and stamping application

Rings and bushings typically for bump and seal applications

Woodworking, e.g., for sawing and planingapplications

Pump pistons for high-performance pumps (e.g., in nuclearinstallations)

Nozzles, e.g., high-performance nozzles for Oil drilling applications

Roof and tail tools and components for high wear resistance

Balls for ball bearing and ball point pen

other grades of tungsten carbide rod

| Grade | YL10.2 | YG6 | YG6X | YG10X | YG8 | YG15 |

| ISO Range | K25-K35 | K20 | K10 | K35 | K30 | K40-K50 |

| WC+others % | 90 | 94 | 94 | 90 | 92 | 85 |

| Co % | 10 | 6 | 6 | 10 | 8 | 15 |

| Grain Size μm | 0.6 | 0.8 | 0.6 | 0.6 | 0.8 | 0.8 |

| Density g/cm3 | 14.5 | 14.9 | 14.9 | 14.5 | 14.6 | 14.1 |

| Hardness HRA | 92.5-92.8 | 89.5 | 92 | 90 | 89 | 86.5 |

| T.R.S N/mm2 | 3800-4000 | 2150 | 2000 | 2200 | 2200 | 2400 |

| Grade | Application |

| YL10.2 | ultra-fine grain WC+ 10% Coblat, with good Wear resistance and Toughness, strength comparatively higher,suitable for PCB micro drills,for making drills,end mill,reamer,taps,burrs etc. |

| YG6 | Fine Grain WC+6% Cobalt, with Good Wear resistance, used for hard wood,processing original wood,aluminum section bar,brass rod and cast iron. |

| YG6X | ultra-fine grain size with cobalt 6%,with good wear resistance,Suitable for processing Chilled cast iron, heat-resistant alloy steel, and fine process of common cast iron |

| YG10X | ultra-fine grain WC+ 10% Cobalt, suitable for small diameter Micro drill ,vertical milling cutter, rotating file |

| YG8 | fine GrainWC+ 8% Cobalt Suitable for the roughening of cast iron and light alloys and also for the milling of cast iron and low-alloy steel. |

| YG15 | fine grain WC +15% Cobalt for mining tools, cold heading and punching dies |

Our Various Size List

D | L | D | L |

(mm) | mm | mm | mm |

| 17.5 | 245 | 15 | 270 |

| 22.225 | 270 | 24 | 276 |

| 20 | 245 | 26 | 277 |

| 33.33 | 277 | 19.7 | 245 |

| 35 | 270 | 32 | 277 |

| .... | .... | .... | ..... |

For more size information, please kindly email or call us.For length, we can cut to any size.

Our packing

Based on Detail products, we use different Standard packing suitable overseas shipment.

For carbide rod packing as following

1. outsizde carton or plywood case

2. inner packing is plastic box or small carton with cotton or paper protection

We always persuit long term business with our clients by our good quality. please do not hesitate to contact us at any time

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com