Molybdenum Products

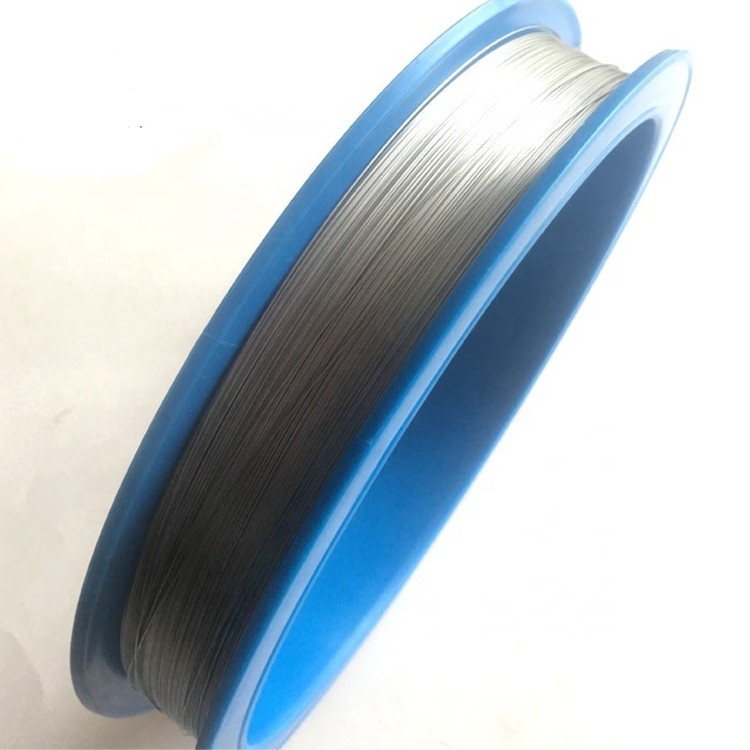

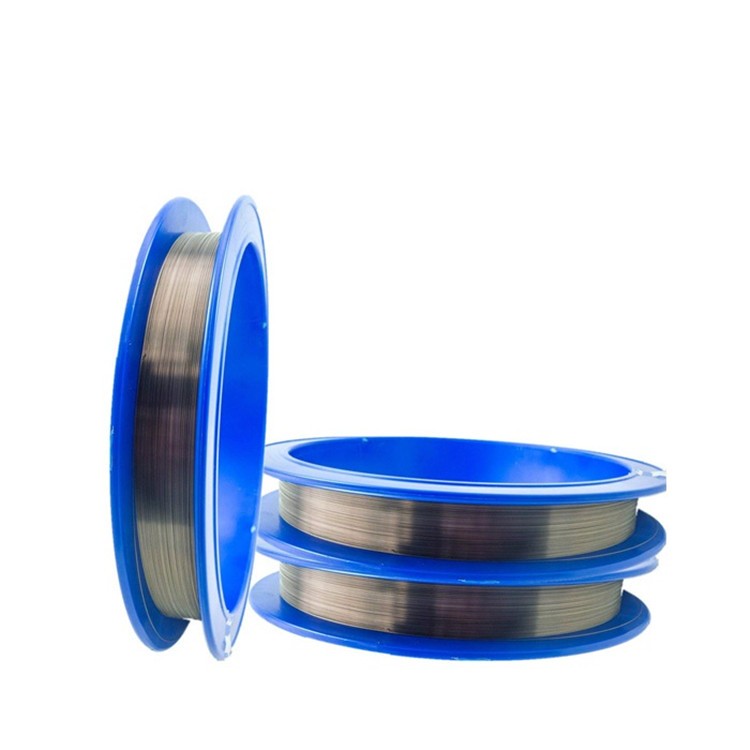

0.4mm White Molybdenum Products / Wire High Melting Point For Lampblack Machine

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF-MW789

- Price:Quote based on drawings

For more information, warmly welcome to contact me

Shirley Pan(Ms)

Email:shirley@chinahardalloy.com

Mobile:+8617773379950

0.4mm White Molybdenum Products / Wire High Melting Point For Lampblack Machine

Chemical Composition

| Grade | 99.95%Mo The impurity content is no more than % | |||||||

| Fe | Ni | Al | Si | Mg | C | O | ||

| Mo-1 | 0.001 | 0.005 | 0.002 | 0.001 | 0.001 | 0.002 | 0.002 | |

| Mo-2 | 0.0015 | 0.005 | 0.002 | 0.001 | 0.002 | 0.002 | 0.002 | 0.008 |

Size Detail

| Diameter(μm) | Weight/200mmmg | Weight/200mm tolerance | Diameter tolerance % |

| 30≤d≤40 | 1.47 -2.61 | ±3.0 | ---- |

| 40<d≤100 | >2.61 – 16.33 | ±3.0 | 7.0 |

| 100<d≤400 | >16.33 – 256.2 | ±3.0 | ---- |

| 400<d≤600 | ---- | ---- | ±2.5 |

| 600<d≤2500 | ----- | ----- | ±2.0 |

1. Grade: Mo1,Mo2,

2. Purity :> =99.95%

3. Characteristic:

Melting Point: 2610 Degrees Celsius

Density: 10.2g/cm3

Dimensions: Dia(0.03-3.25)mm

4. Certificate: GB/T9001:2015/

5. Product Feature:

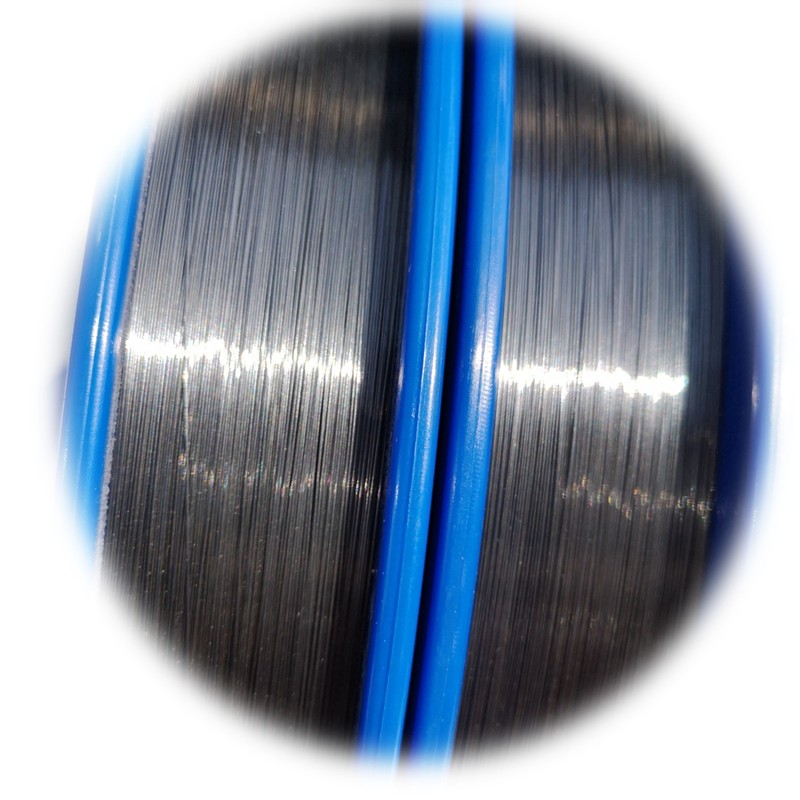

• High melting point, Low density and Thermal coefficients

• Good thermal conductivity properties and Resistance of high-temperature

• High tensile strength and Low elongation

• Good stability and High precision of cutting

• High speed and Long stable time of processing

• Long lifetime and Non-poisonous

• It has the lowest heating expansion of any commercially used metal. Mo.

Used in section bar cutting, H2 furnace, heater rod guide bar hook, mandrel, electric wire and plumbum etc.

Used for making heat resisting facility, such as support, guide bar, heating rod in a furnace etc.

Used in molybdenum furnace and tube socket high temperature thermal field

Specification: molybdenum rod

1. We produce pure and lanthanide doped molybdenum alloy rod;

2. Molybdenum rod can be divided into 2 kinds: Forging molybdenum rod allows to have oxidized film and slight forging hammer mark; the surface of polished molybdenum rod presents metallic luster and has no-oxidized phenomenon notably; the two surfaces have no defects, such as divided layer, crackle, burr and vertical crackle, etc.

3. Molybdenum rod is manufactured in random length pieces or cut to customers' desired lengths with diameters ranging from 3mm to 5mm.

Advantage of our Molybdenum wire

1 uniform grain with densified microstructure ensures longer use time.

2 High special strength,high melt point.

3 excellent corrosive resistance,good thermal resistance.

4 professional after-sales service

Package:

Coils wrapped with waterproof paper with plywood case outside.

Shipping:

A. Express Delivery (DHL, TNT or FedEx)(Small sizes and less than 50 kg)

B. Air Cargo Delivery (Weight Over 50 kg)

C. Sea Shipping Delivery (LCL&FCL)

Payment: T/T, L/C at sight, Paypal, Western Union or as your inquiry

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com