Custom Tungsten Carbide Parts

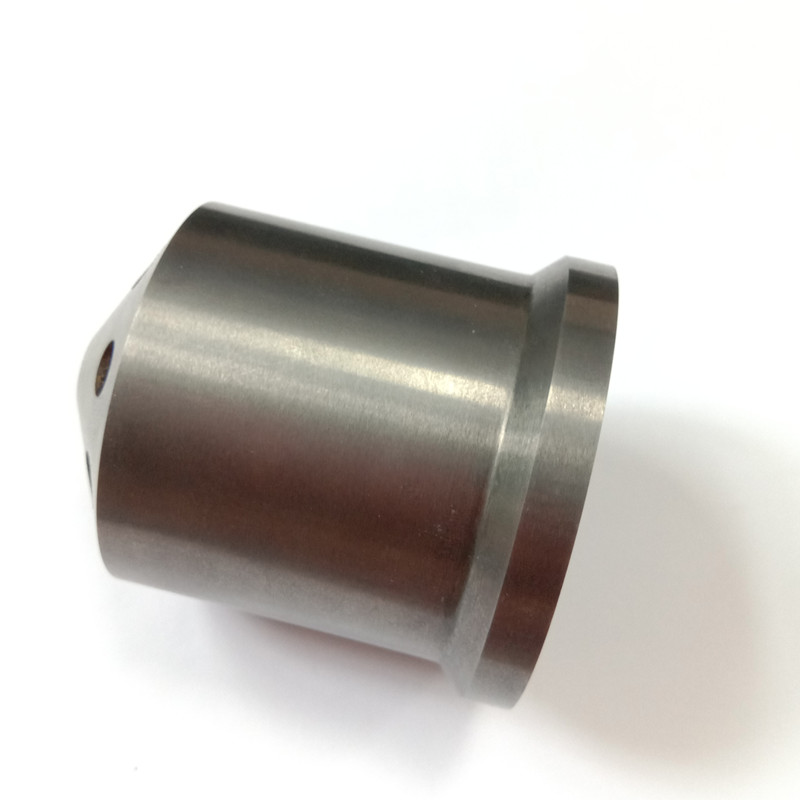

High Wear Resistance Custom Solid Tungsten Carbide Guiding Sleeve

- Place of Origin: Zhuzhou, Hunan

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: YN9 YN8 YG8 Yg6

- Price:Quote based on drawings

High Wear Resistance Custom Solid Tungsten Carbide Guiding Sleeve

Tungsten carbide bushing set up by virgin tungsten carbide material. It’s shows high hardness and bending strength. That has superior performance on resisting abrasion and corrosion, which is widely used in many industries.

In addition, differ from the various of application environment. There are several types of Tungsten carbide bushing. Most of the specifications are all customized.

Grade of tungsten carbide bushing

Tungsten carbide bushing applications is wide, which is a device to protect a class of components. It is in the actual work and the role and purpose of its application environment have a great relationship.

Tungsten carbide bushing production and processing of high-strength, can withstand prolonged load, with high chemical stability, alkali, alcohol, ether, hydrocarbons, acid, oil, detergent, water (sea water), and has no smell , non-toxic, tasteless, non-rust characteristics, its widely used in petrochemical industry for Submerged Oil Pump, slurry pump, water pump, Centrifugal Pump,etc.

Flow Guiding Application

As wear parts,guiding flow in the expansion joint, protecting the bellows

Product feature of tungsten carbide Sleeves1. High hard resistance

2. High corrosion resistance

3. Pressured resistance

4. Wear resistance

5. High bending strength

For more infomation, please contact me

Ms shirley Pan

Email: sales@chinahardalloy.com

Mobile: +86 17773379950

Categories

News

Contact Us

Quote based on drawings

Phone: 0731-28214800

tel: +86 17773379950

E-mail: sales@chinahardalloy.com