Carbide Wear Parts

3D Bending Glass Tungsten Carbide Mould Cemented Carbide Plates for Mobile Phone 3D Glass Screen

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: K10 K20 K30

- Minimum Order Quantity:10 pcs

- Price:USD 45-58/kg

- Delivery Time:7-15 days

- Payment Terms:L/C, D/A, D/P, T/T, Western Union etc

- Supply Ability:100000 pcs/month

3D Bending Glass Tungsten Carbide Mould Cemented Carbide Plates for Mobile Phone 3D Glass Screen

*3D Bending Glass Tungeten Carbide Plates Information:

Tungsten Carbide Mould 3D hot bending glass,also known as the 3D hot bending glass tungsten carbide mould heating transfer plate,belongs to the hot bending machine supporting the use of glass heating transfer plate,high temperature materials.

Mobile phone 3D glass screen,the most important thing in the production of glass lenses is hot bending forming. In the hot bending machine evenly heat in the process of high temperature hot pressing glass need to use to the high temperature resistant,thermal conductivity of the powder metallurgy heating transfer plate to heat evenly hot pressing operations.Here,the heating temperature up to 950 ℃ to 1150 ℃ or higher, such a high temperature for 3D hot bending glass tungsten carbide mould is also have special requirements,and glass materials under the environment of high temperature have strong corrosion effect. Should not only guarantee the high hardness and density of heating transfer plate,and to ensure that the high-temperature thermal deformation and strong corrosion resistance,the powder metallurgy is a new material new materials application and the challenge.

Powder metallurgy is producing metal powder or with metal powder as raw material,after forming and sintering,manufacturing metal materials,composite materials and processing technology of various types of products. For 3D glass hot bending machine high temperature hot pressing operations using powder metallurgy material,work in the high temperature of 950 ℃ to 1150 ℃ hot pressing under strong antioxidant capacity,but also has good thermal stability at high temperatures and micro deformation.

*Recommend Grades of TC Plates:

*Gingte Carbide Plates Size Chart:

| (unit):mm | ||

| L | W | S |

| 40 | 40 | 2~20 |

| 50 | 50 | 2~20 |

| 68 | 57 | 2~20 |

| 60 | 50 | 2~20 |

| 100 | 50 | 2~50 |

| 100 | 100 | 3~65 |

| 105 | 105 | 3~65 |

| 120.5 | 107 | 3~45 |

| 120.5 | 120.5 | 3~65 |

| 140 | 65 | 3~65 |

| 140 | 60 | 3~65 |

| 140 | 55 | 3~65 |

| 140 | 50 | 3~65 |

| 150 | 100 | 3~65 |

| 150 | 150 | 3~45 |

| 165 | 65 | 2~50 |

| 165 | 60 | 2~50 |

| 165 | 50 | 2~50 |

| 200 | 60 | 2~50 |

| 200 | 200 | 3~65 |

| 200 | 100 | 3~65 |

| 200 | 150 | 3~65 |

| 250 | 250 | 3~65 |

| 250 | 200 | 3~65 |

| 250 | 150 | 2~50 |

| 250 | 130 | 3~65 |

| 270 | 120 | 2~50 |

| 300 | 250 | 2~30 |

| 300 | 200 | 2~30 |

| 300 | 160 | 2~20 |

| 320 | 215 | 2~30 |

| 350 | 250 | 2~30 |

| … | … | |

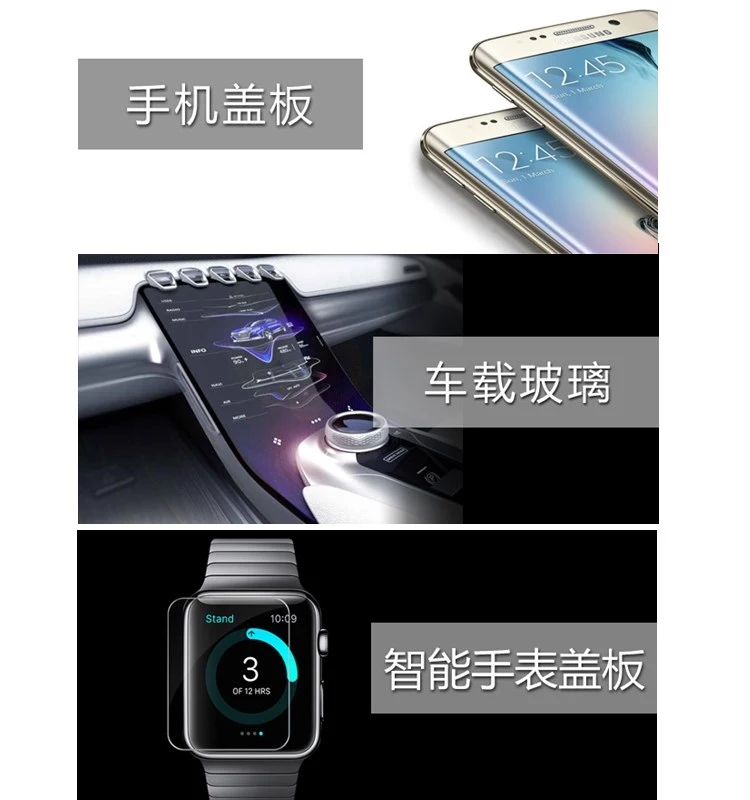

Application Are: 3D Hot bending Glass Molding Machine

Our advantage

1. We are factory ,guarantee competitive price and high quality.

2. High density,Good machinability ,High modulus of elasticity ,Strong corrosion resistance Non-poisonous ,Good mechanical properties

3. 100% QC inspection Before Shipment.

4. We guarantee that all of our products are used with 100% Virgin Raw Material.

5.Customization is avaliable

If have any more information, please feel free to contact with me.

Tel: 0086-731-28215800

Fax: 0086-731-28215800

Mobile: 0086-13823202651(wechat/whatsapp)

Email address:sharon@chinahardalloy.com

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 6A-block,Tianyikeji industrial park, Qunfeng town, Tianyuan district, Zhuzhou, Hunan, China 412000