Carbide Wear Parts

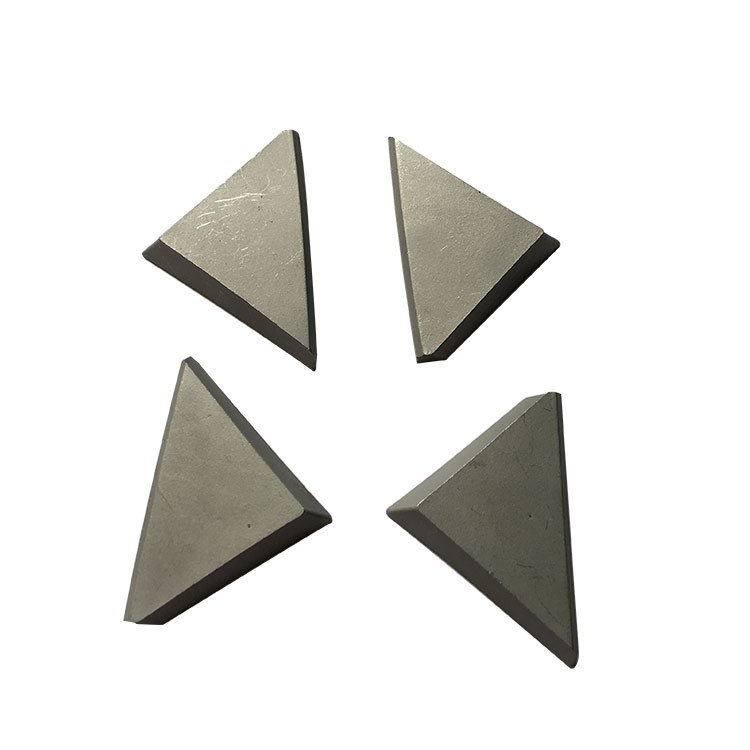

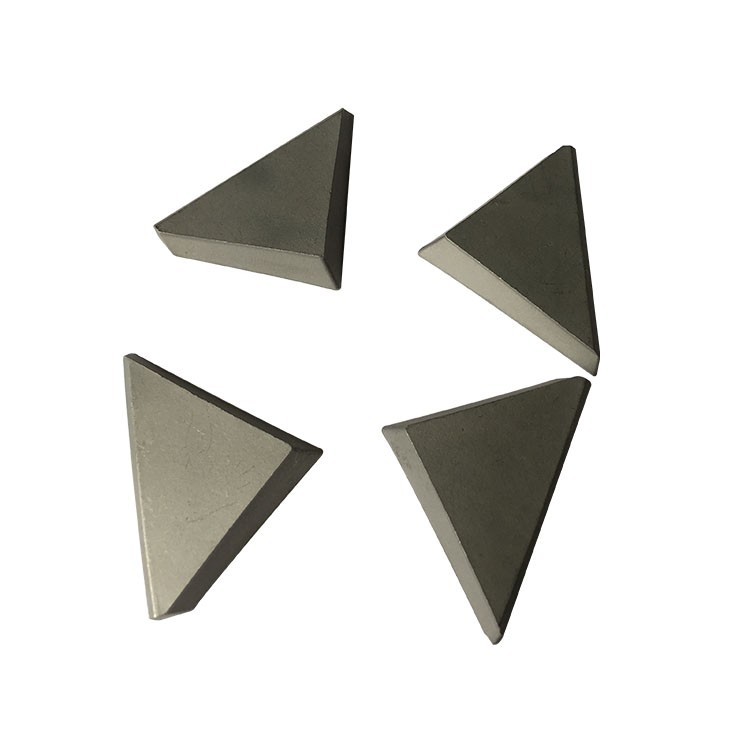

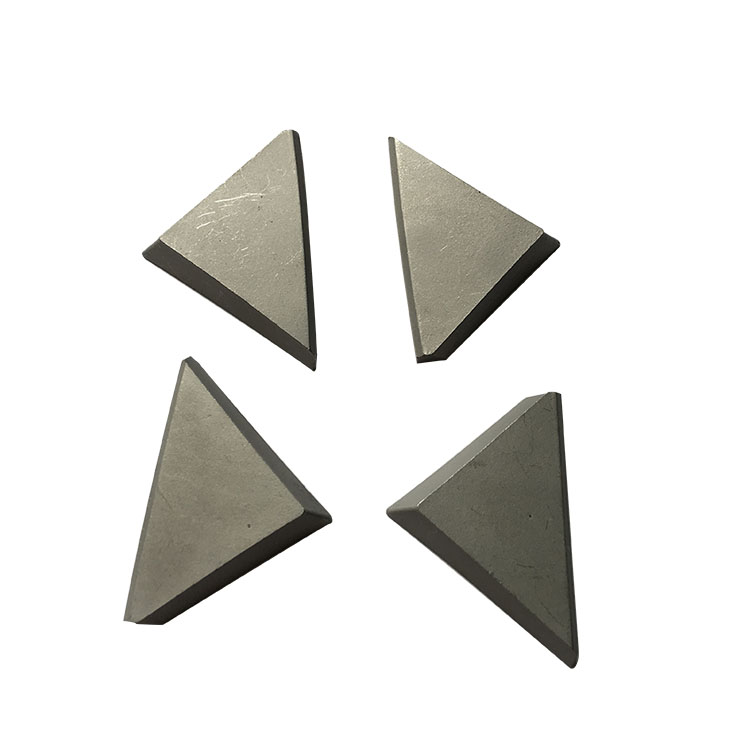

Custom triangle Tungsten carbide inserts for wood cutting

- Place of Origin: China

- Brand Name: Zhenfang

- Certification: ISO9001:2015

- Grade: ZF00133

- Minimum Order Quantity:1000 pcs

- Price:USD 45-58/kg

- Delivery Time:7-15 days

- Payment Terms:30% after confirming order the balance before shiping

- Supply Ability:100000 pcs/month

Custom triangle Tungsten carbide inserts for wood cutting

Features of Tungsten carbide products

1) Full range of types available, more convenient for you to purchase;

2) Various grades available, therefore can provide full machining solutions;

3) Produced with precision molds, the products have better dimensional accuracy and uniform;

4) Careful surface treatment, ensuring perfect appearance, increasing customer satisfaction;

5) Made of top-quality raw material, have more stable properties, easier to braze, also extend its service time.

Application:

The cemented carbide brazed tips have wide application, like for cutting and processing cast iron, stainless steel, and other alloy steel, etc., especially for lathes and periphery grinders and so on.

Mains Grade for Custom triangle Tungsten carbide inserts for wood cutting

Grade No. | Density (g/cm³) | Hardness (HRA) | T·R·S (MPa) | Application Recommended |

| YG6 | 15.80 | 89.5 | 1700 | Mainly used as the buttons of small and medium-sized percussion bits and as the inserts of rotary prospecting bits to cut soft, medium-hard formations. |

| YG8 | 14.70 | 88.5 | 2300 | Mainly used as the buttons of small and medium-sized percussion bits and as the inserts of rotary prospecting bits to cut soft, medium-hard formations. |

| YG11C | 14.40 | 86.5 | 2450 | Chiefly for the inserts and buttons of heavy rock drill bits and rotary-percussive bits, coal-cutting bits and tricone bits to cut medium-hard and hard formations. |

| YG13C | 14.30 | 86.0 | 2500 | It is stronger, and is mainly used as the inserts and buttons of rotary-percussive bits, heavy rock drill bits to cut hard and very hard formations. |

| YG15 | 14.00 | 86.5 | 2500 | It is stronger, and is mainly used as the inserts and buttons of rotary-percussive bits, heavy rock drill bits to cut hard and very hard formations. |

| YG20 | 13.40-13.70 | 85.0 | 2254 | Mainly for the stamping dies used in the conditions of heavy impact load and large strees |

6. Tungsten Carbide Circular Blade

Company introduction

1 We are a Real Factory in Zhuzhou City.

2. High density,Good machinability ,High modulus of elasticity ,Strong corrosion resistance,Non-poisonous ,Good mechanical properties

3.100% QC inspection Before Shipment.

4. We guarantee that all of our products are used with 100% Virgin Raw Material.

5. We can produce the Special Non-standard Shaped Carbide Products as per your sample or drawing.

Zhuzhou Zhenfang Yaguang Tungsten-Molybdenum Co.,LTD is a professional manufacture in tungsten carbide field. We have engaged in this field for over ten years. We have rich experience on tungsten carbide studying and manufacture.We pursuit providing efficient solution and high quality products for clients. We specialize in tungsten carbide rod, carbide plate&strips, carbide dies, carbide roller, carbide wear parts for petrochemical industry, carbide cutting tools.Tungsten carbide rod and customized wear parts is our advantage.

We always keep good relationship with our clients, enhancing communication and Cooperation to each other, trying to create WIN--WIN cooperation.

If have any further problem, please feel free to contact with me.

Contact information

contact person:Ms Sharon Chen

Mobile number:86-18173388506

email address:sharon@chinahardalloy.com

webiste:www.wmcarbide-rods.com

Categories

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

- Tungsten carbide rod with coolant hole

- Solid Carbide Rods

- Cemented Carbide Rods

- Tungsten carbide rod

- Ground Tungsten Carbide Rod

- Tungsten Carbide Drill Blanks

- Tungsten Carbide Round Bar

- tungsten carbide blade

- Carbide Wear Parts

- Custom Tungsten Carbide Parts

- Tungsten Carbide Nozzle

- Tungsten Products

- Molybdenum Products

- Plunger

- carbide fin form tool

News

Contact Us

Contact: Quality Tungsten Carbide Rod

Phone: 0731-28214800

Tel: +86 17773379950

E-mail: sales@chinahardalloy.com

Add: 7 buildings in area C, High-tech Auto parts City, Zhongda Road, Tianyuan District, Zhuzhou City, Hunan Province.